Underway metal monitoring equipment

A metal monitoring and navigation technology, which is applied in the preparation of test samples, measurement devices, color/spectral characteristics measurement, etc., can solve the problems of low work efficiency, inability to realize real-time navigation detection, and cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

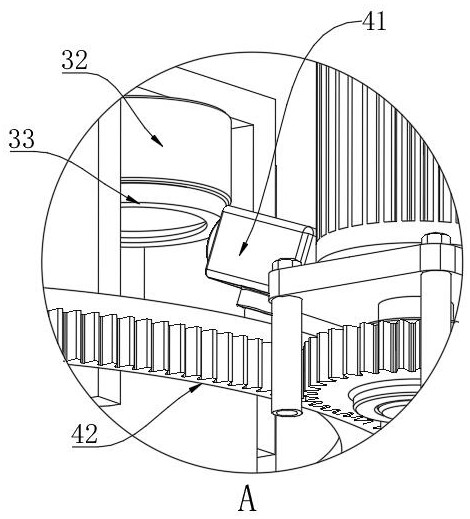

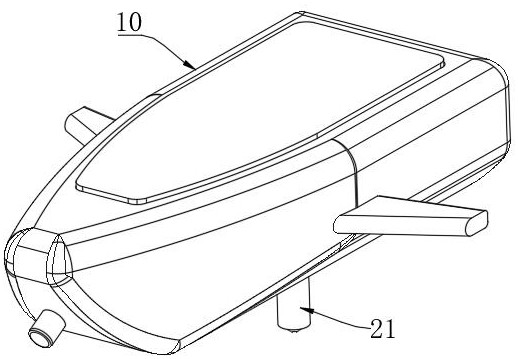

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the embodiments described in the present invention are part of the embodiments of the present invention, not all of them .

[0038] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require further definition and explanation in subsequent figures.

[0039] In the description of the present invention, it should be noted that the terms "parallel", "perpendicular" and the like do not mean that the components are required to be absolutely parallel or vertical, but may be slightly inclined.

[0040] In the description of the present invention, it should also be noted that, unless otherwise clearly specified and limited, the term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com