Fan base, fan overall equipment and fan vibration control method

A fan, integrated technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as unfavorable vibration response control, high frequency, and eccentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

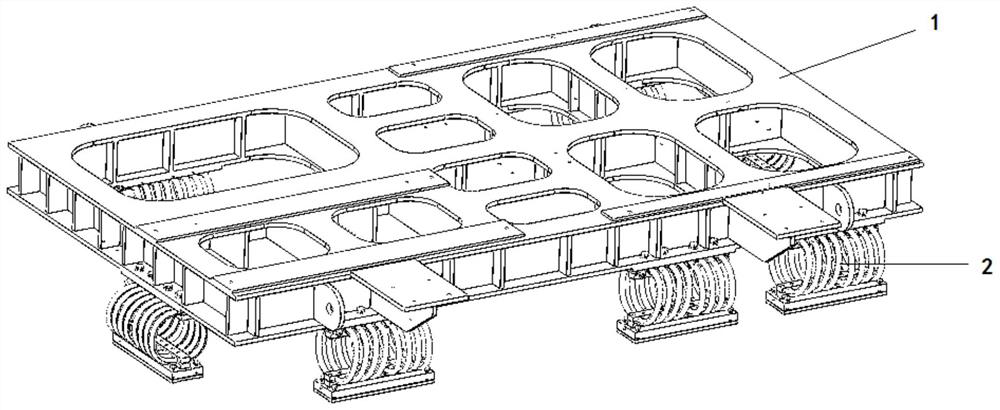

[0033] see image 3 , the present invention provides a fan base 1, the stiffness of the fan base 1 is improved by diagnosing the faults existing in the existing fan base according to the modal vibration data of the model; the fan base 1 is provided with a wire rope isolator 2 .

[0034] Working principle: the fan base 1 of the present invention increases the first-order natural frequency of the fan base 1 by improving the stiffness characteristics. The wire rope vibration isolator 2 reduces the first-order natural frequency of the fan base 1 and improves the vibration isolation efficiency of the fan base 1 .

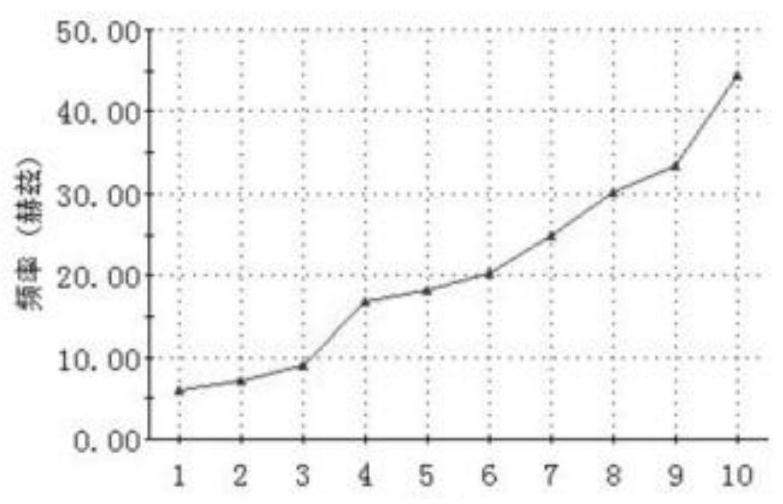

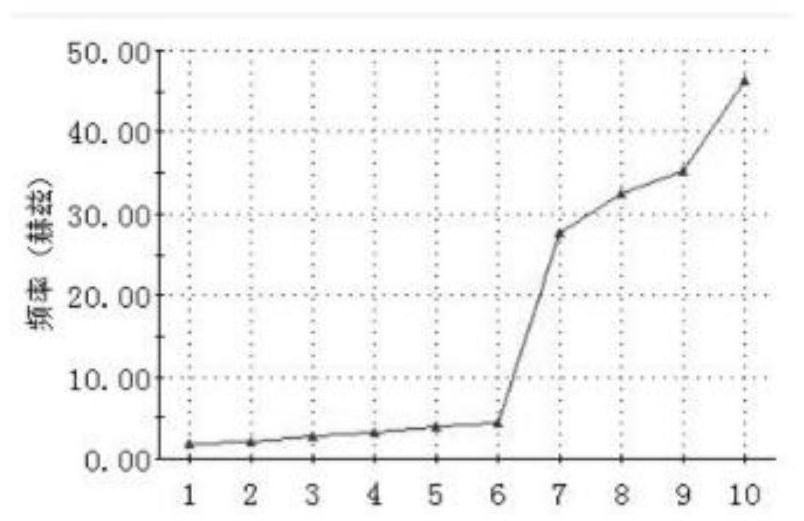

[0035] Further, the modal vibration data of the model is obtained by performing SOLIDWORKS modeling on the existing fan base according to the actual state of the on-site fan in the factory and mine, and using the finite elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com