Reclamation-area factory building column foundation and construction protection method thereof

A plant column and foundation technology, applied in basic structure engineering, protection devices, buildings, etc., can solve the problems of long construction period, complex wall construction process, poor economic benefits, etc., to save steel consumption, improve stiffness characteristics, The effect of increasing economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

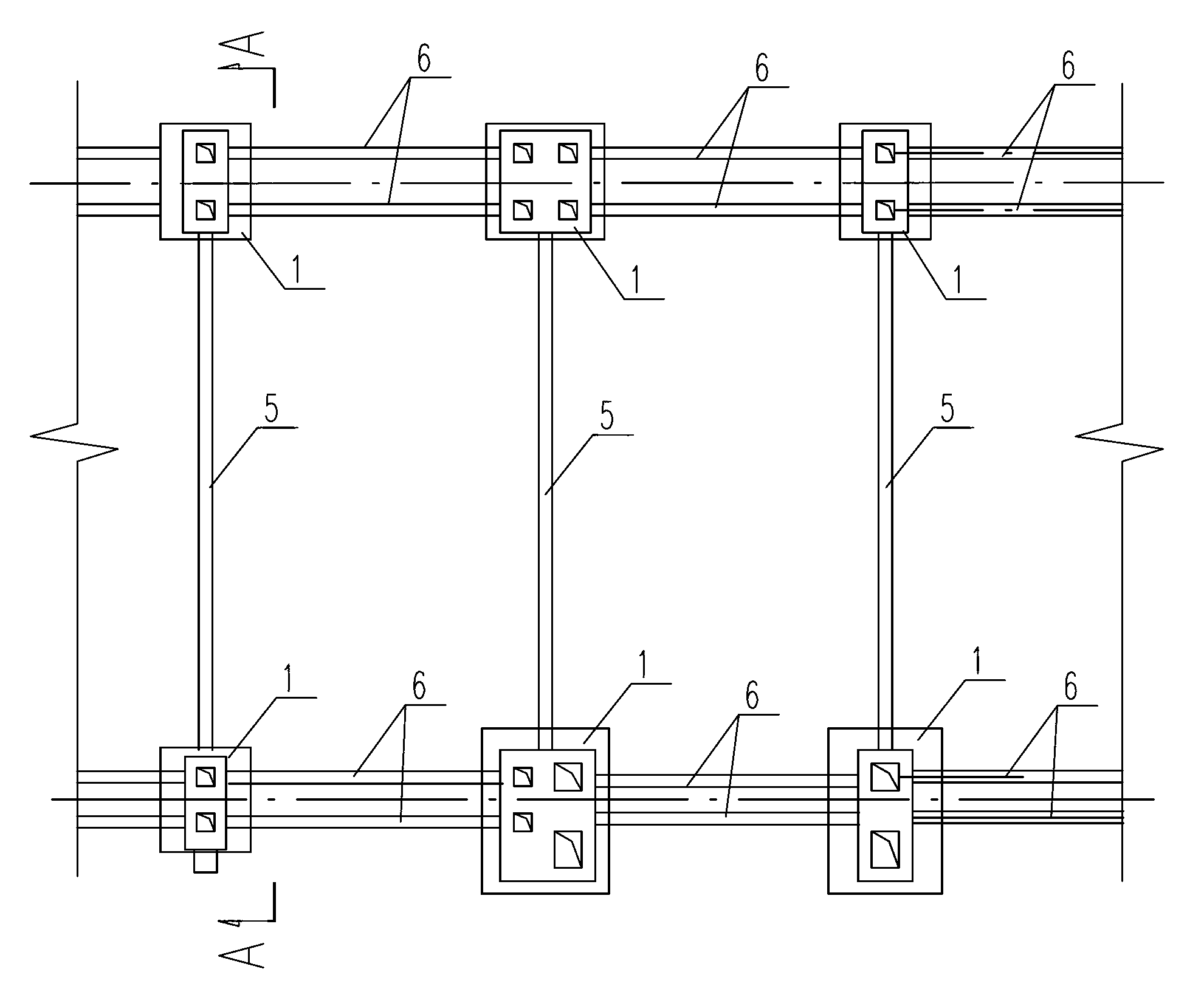

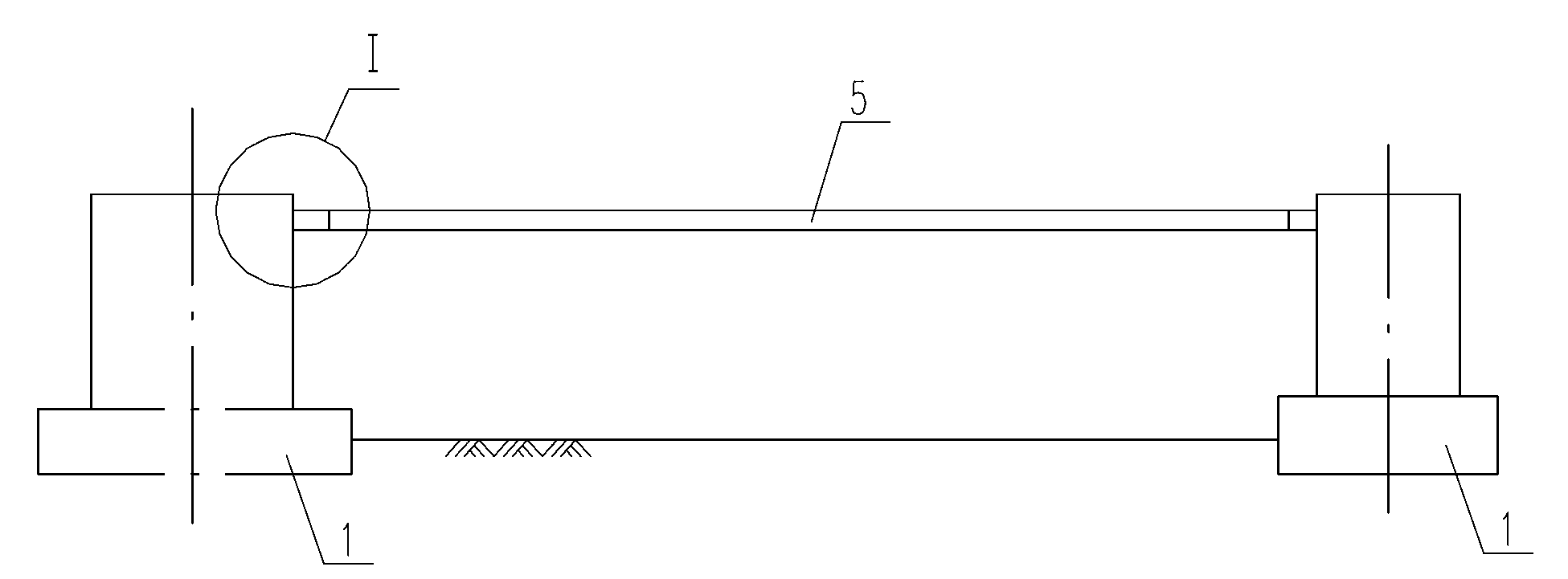

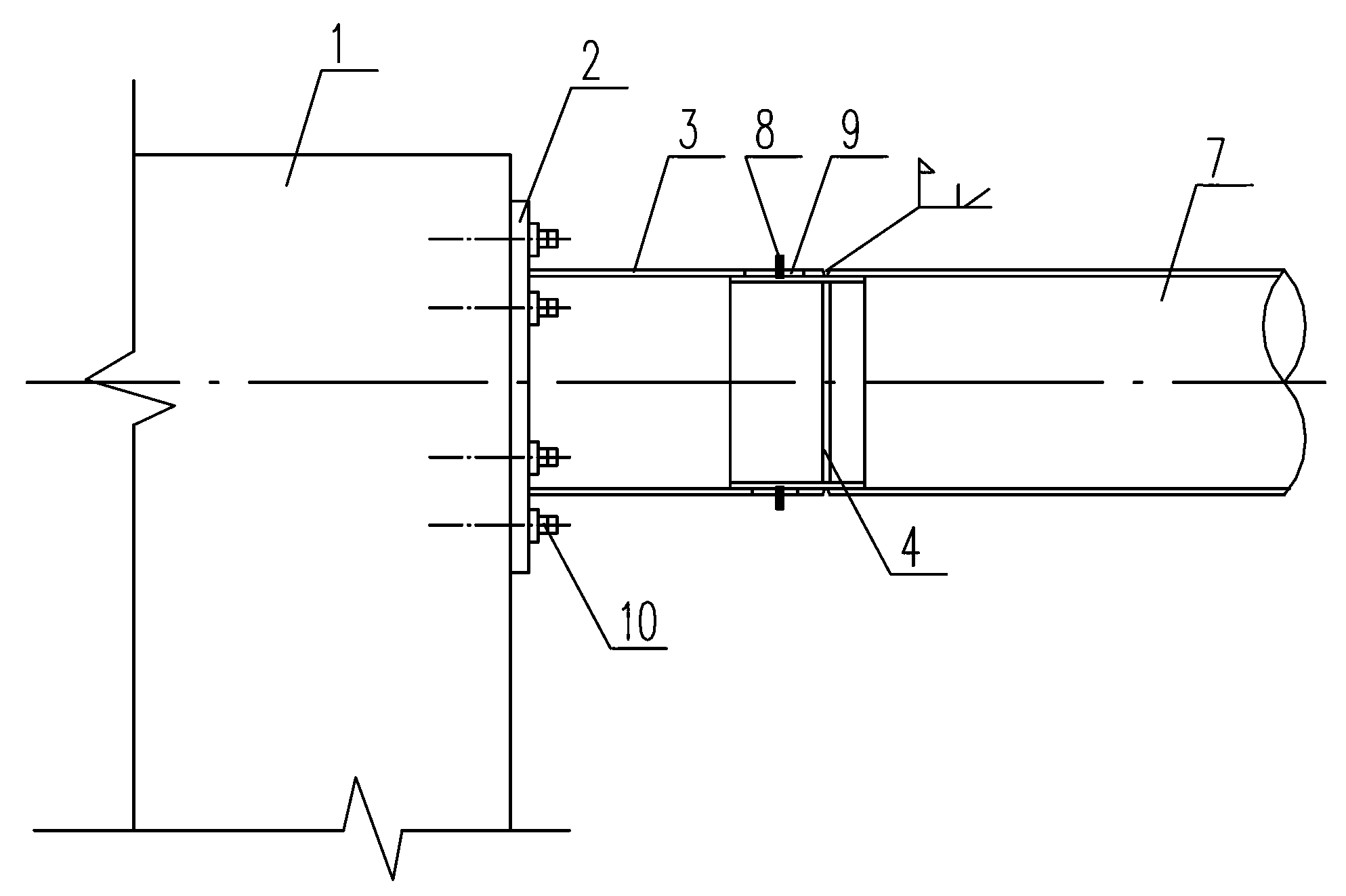

[0017] Such as figure 1 , is a schematic diagram of the plane structure of the column foundation construction of the factory building of the present invention. The column foundation body 1 is located in the reclamation area, and its vertical adjacent column foundation bodies 1 are connected by concrete longitudinal connecting beams 6, and the horizontal span adjacent column foundation bodies are passed through a process. The top pipe 5 is connected. Determine the span, section, and reinforcement of the concrete longitudinal connecting beam 6 according to the column spacing and load of the factory building, and complete the pouring of the concrete longitudinal connecting beam 6; then determine the length of the process pipe jacking 5 according to the span and geological conditions of the factory building. Load calculation process The diameter and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com