Electric control gear shifting device for new energy vehicle

A technology of new energy vehicles and shifting devices, which is applied in the direction of transmission, gear transmission, transmission control, etc. It can solve the problems of difficult shift deceleration, brake disc overheating, difficult shift precise control, etc., to protect driving safety , to ensure the effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

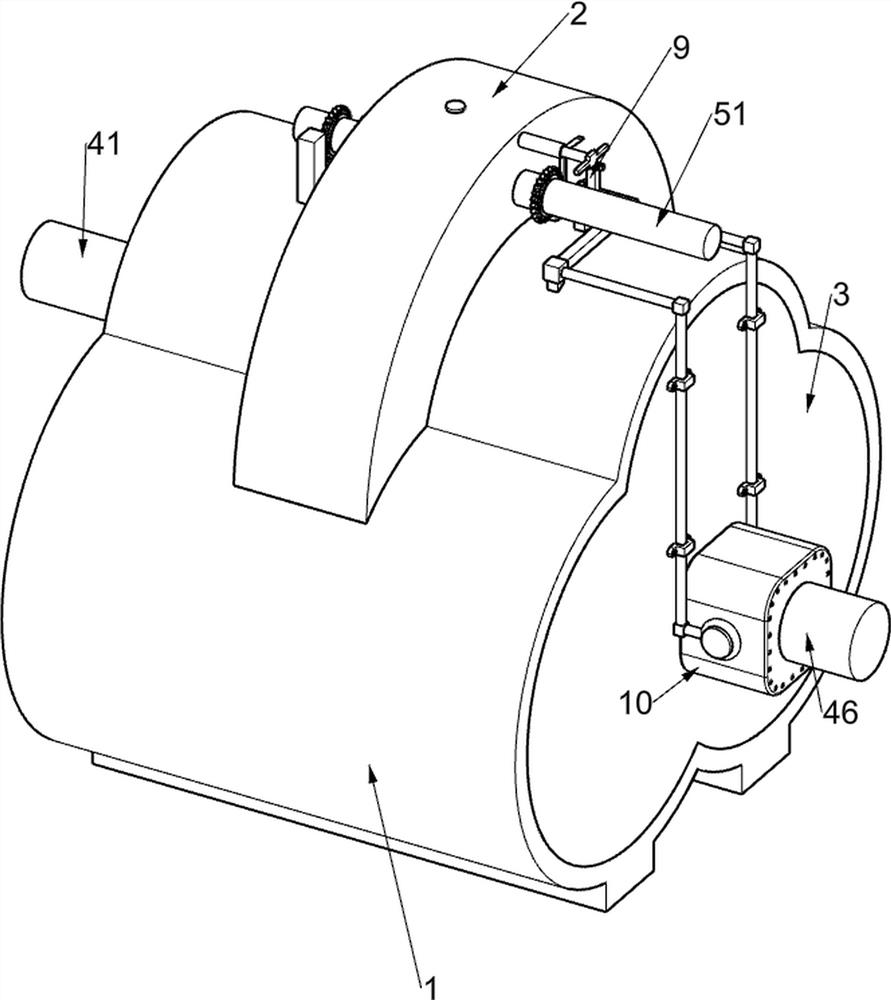

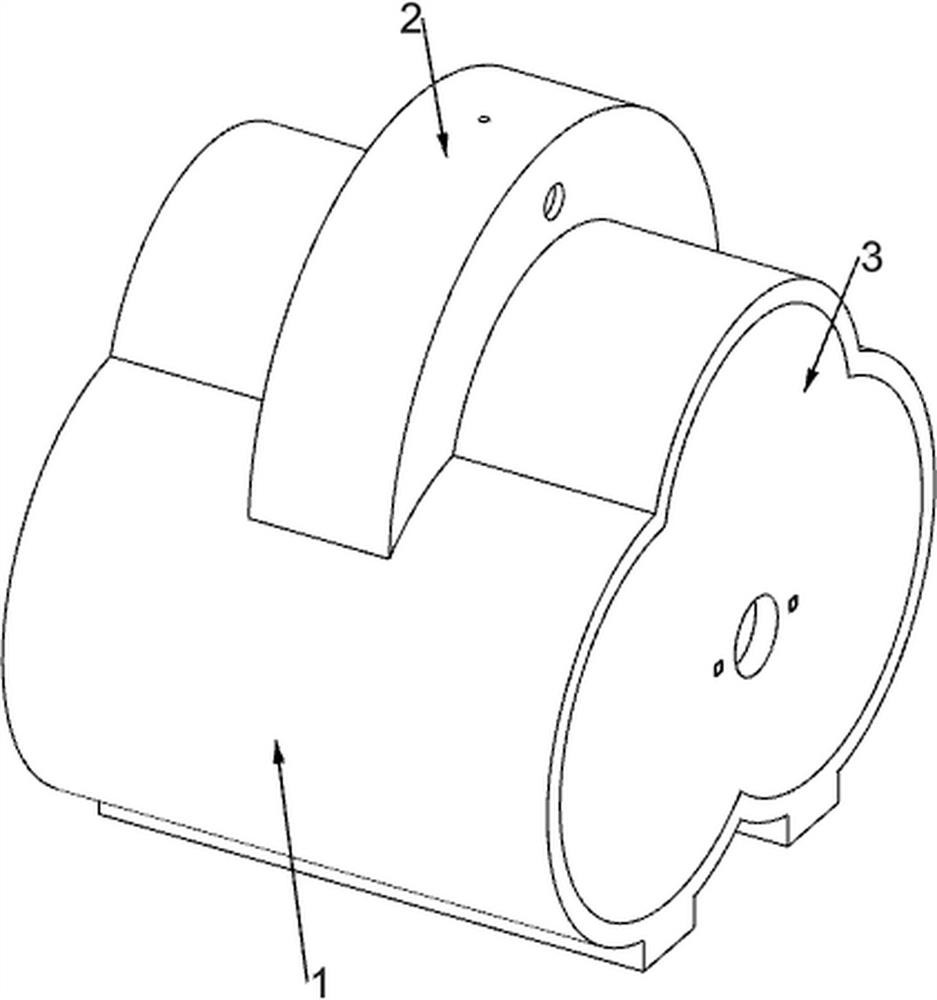

[0037] Electronically controlled shifting devices for new energy vehicles, such as Figure 1-11 As shown, it includes a bottom frame 1, an arc-shaped protection frame 2, a cover plate 3, a rotating assembly 4, a manual shift assembly 5, and a sliding sleeve assembly 6. The top of the bottom frame 1 is fixedly installed with an arc-shaped protection frame 2, and the bottom frame 1 Cover plates 3 are fixedly installed on both sides. The two cover plates 3 are jointly rotatably connected with a rotating assembly 4. The engine drives the car through the rotating assembly 4. The arc protection frame 2 is rotatably connected with a manual shift assembly 5. The gear assembly 5 is used for shifting gears of the automobile, and the sliding sleeve assembly 6 is arranged on the rotating assembly 4 .

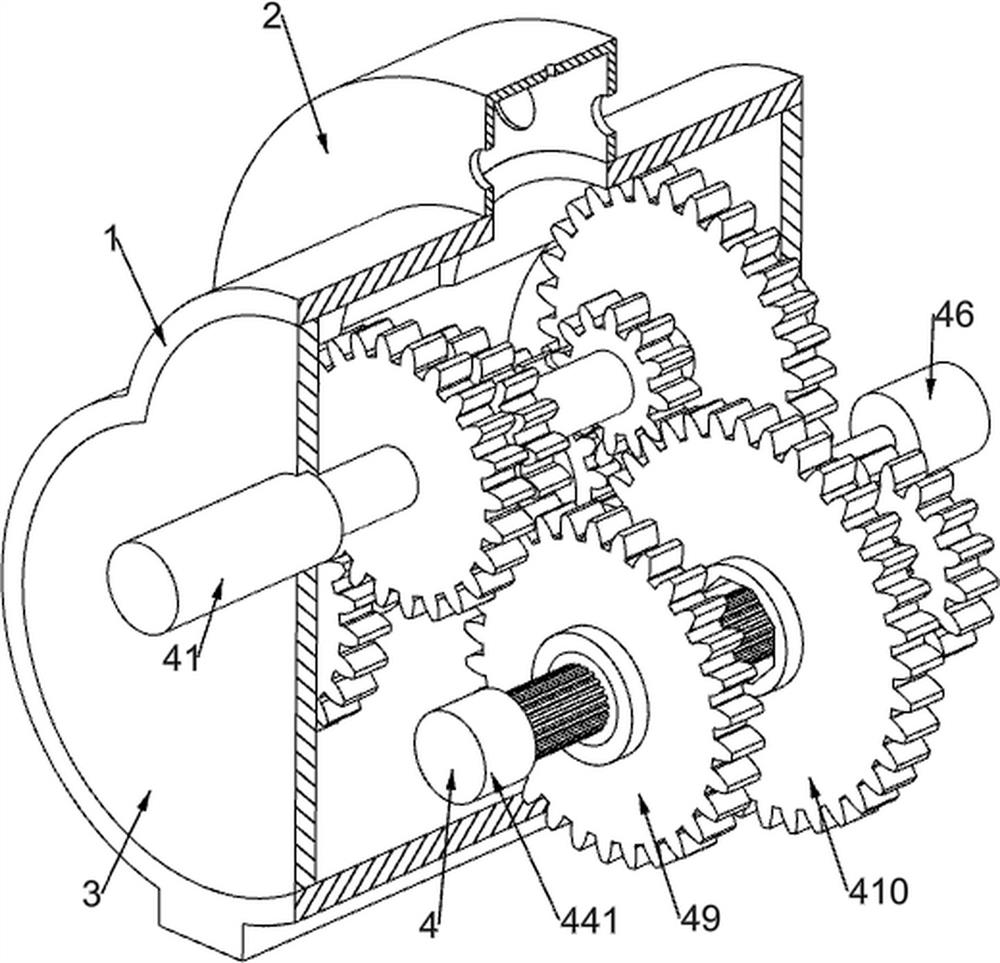

[0038] Rotating assembly 4 includes input shaft 41, transmission gear one 42, transmission gear two 43, transmission gear three 431, transmission gear four 44, spline shaft 441, connecting ...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 8 As shown, it also includes a limit assembly 7, the top of the arc protection frame 2 is slidingly connected to the limit assembly 7, the limit assembly 7 is used to limit the transmission lever 51, and the limit assembly 7 includes a slotted limit wheel 71, clamping lever 72 and second reset spring 73, slotted limit wheel 71 is fixedly connected on the transmission lever 51, and clamping lever 72 is slidably connected to the top of the arc protection frame 2, and clamping lever 72 is connected with the slotted limiting wheel 71 contacts, the clamping rod 72 is used to clamp the slotted limit wheel 71 , and a second return spring 73 is connected between the clamping rod 72 and the arc protection frame 2 .

[0047] The rotation of the transmission lever 51 will drive the slotted limiting wheel 71 to rotate, and the slotted limiting wheel 71 will push the clamping rod 72 to move upwards, and then the compressed second return spr...

Embodiment 3

[0049] On the basis of Example 1, such as Figure 9-10 As shown, it also includes an uphill and downhill electronically controlled shifting assembly 8. The uphill and downhill electronically controlled shifting assembly 8 is fixedly installed on the top of the bottom frame 1. The uphill and downhill electric control shift assembly 8 includes an I-shaped support frame 81, a speed sensor 82, an adjustment gear 83, an overrunning clutch 84, an arc slotted frame 85, a sliding rack frame 86, an electromagnetic block 1 87 and a first homing Spring 88, the right side of the cover plate 3 on the left is fixedly installed with an I-shaped support frame 81, and three speed sensors 82 are fixedly installed on the I-shaped support frame 81, the input shaft 41 runs through the top speed sensor 82, and the spline shaft 441 runs through the bottom Two speed sensors 82, the speed sensor 82 is used to detect the gap between the rotation speed of the key shaft 441 and the output speed of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com