Chain-driven sliding door

A chain-driven, sliding-lifting technology, applied in the field of sliding doors, can solve problems such as door leaf rising obstruction, door leaf descending speed limit, wire rope breaking, etc., to prevent winding or de-grooving, force balance parallel synchronization, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

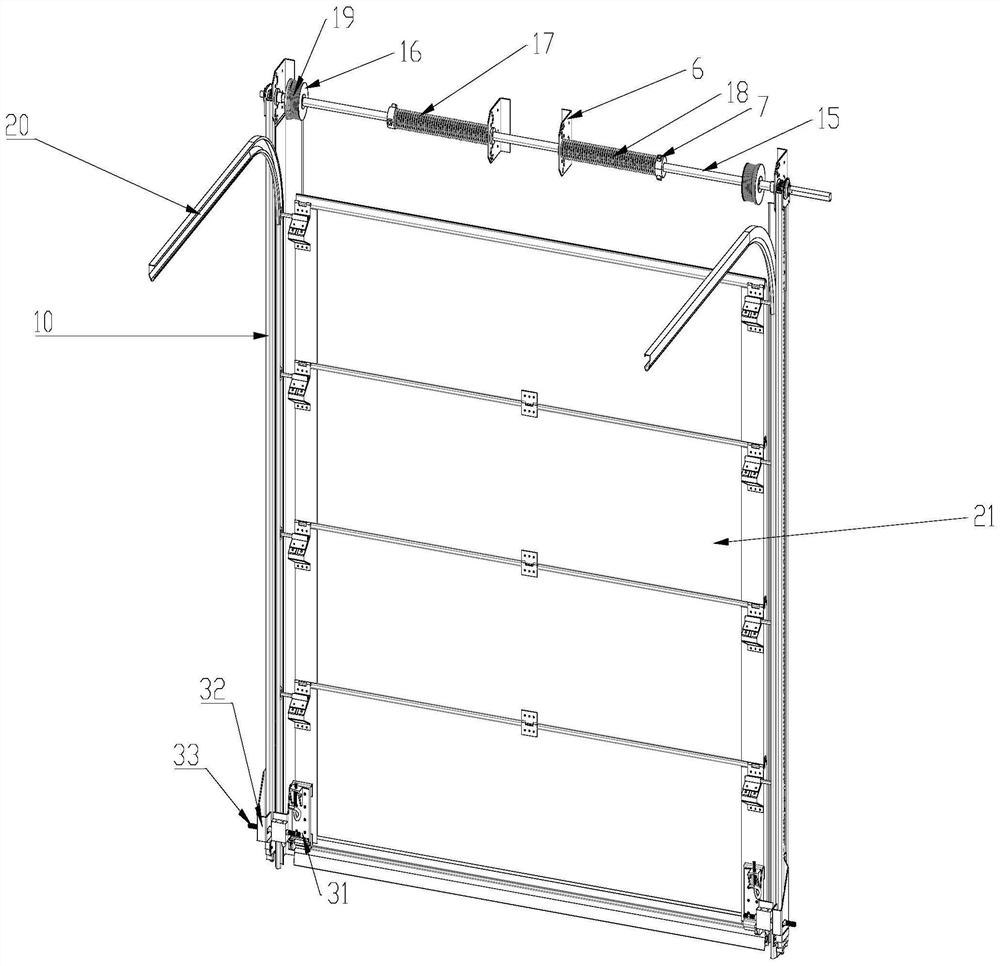

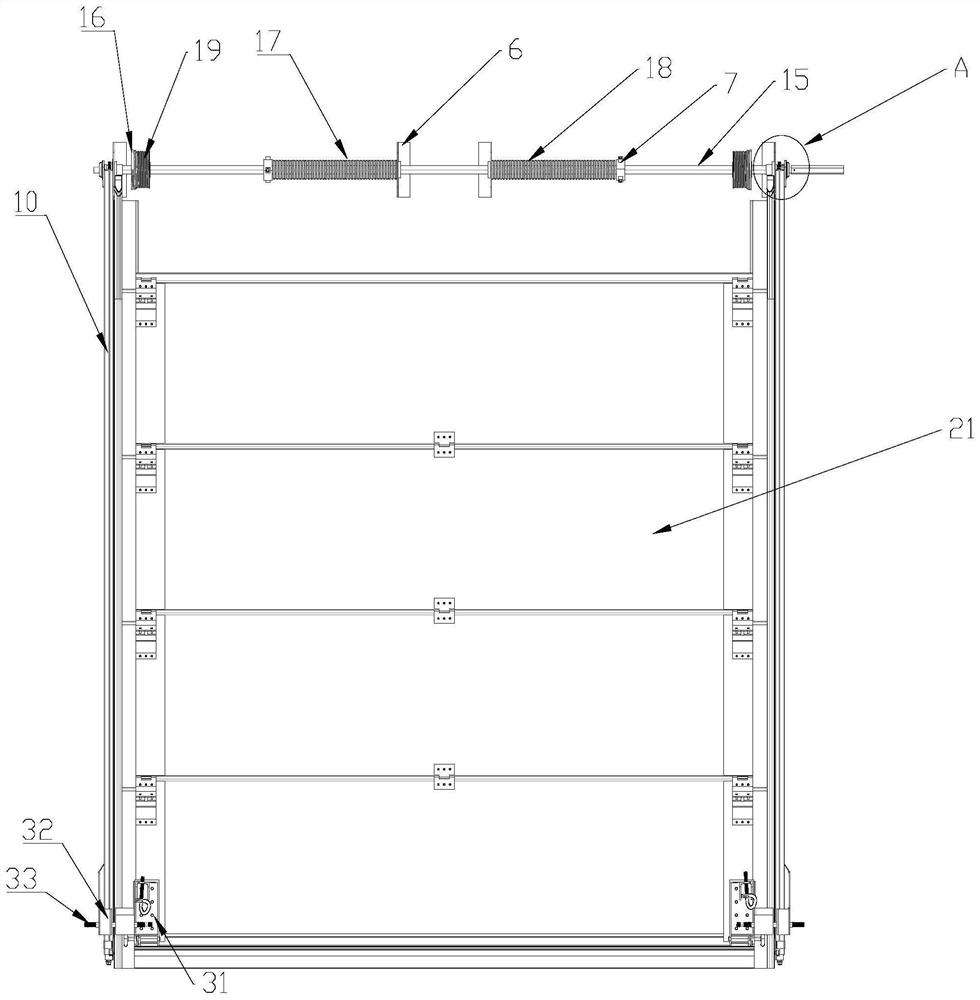

[0029] refer to Figure 1-3 As shown, this embodiment includes a straight rail frame 10 and a curved rail frame 20, the curved rail frame 20 is located in the straight rail frame 10 and is fixedly connected with the straight rail frame 10, and the curved rail frame 20 is provided with There is a door leaf 21, the inside of the curved rail frame 20 is provided with slide rails, and the two sides of the door leaf 21 are provided with pulleys, so that the door leaf 21 can lift and slide on the slide rails inside the curved rail frame 20 through the setting of the pulleys, thereby improving the height of the door leaf. 21 do the stability of slide-up motion on curved rail frame 20.

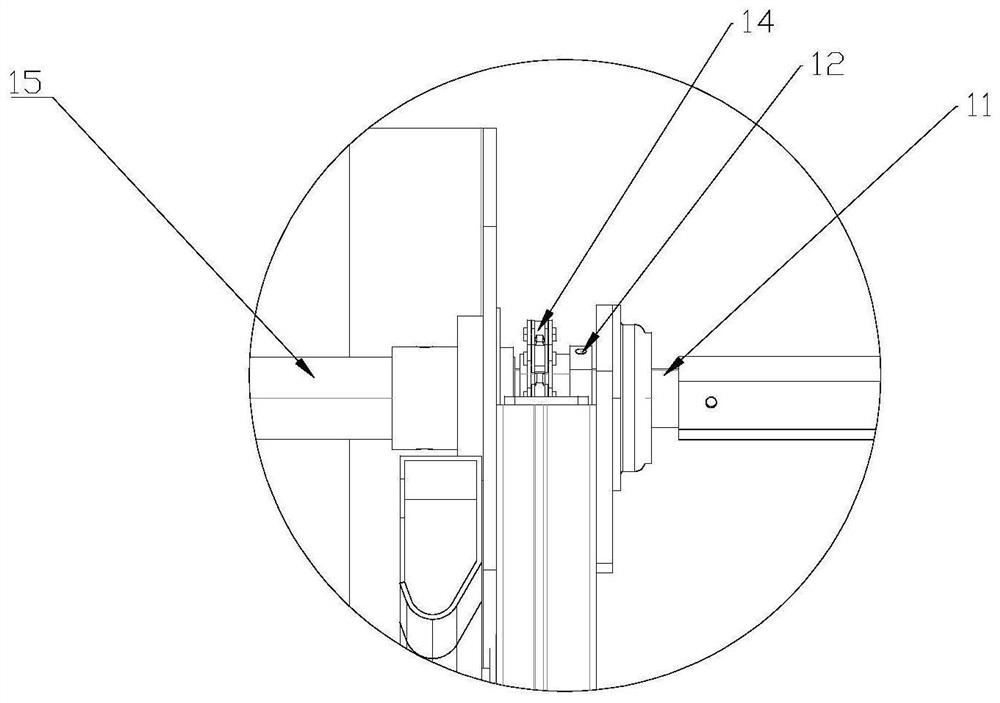

[0030] The top of the straight rail frame 10 is provided with a solid drive shaft 11, the solid drive shaft 11 is covered with a hollow drive shaft 15, the hollow drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com