Assembly type ceramic-aluminum acoustic panel

A sound-absorbing panel and prefabricated technology, applied in the field of architectural decorative panels, can solve the problems of damage to the integrity of ceramic aluminum panels, affecting the use effect, poor maintenance performance, etc., to avoid interference and collision, improve assembly quality and efficiency, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

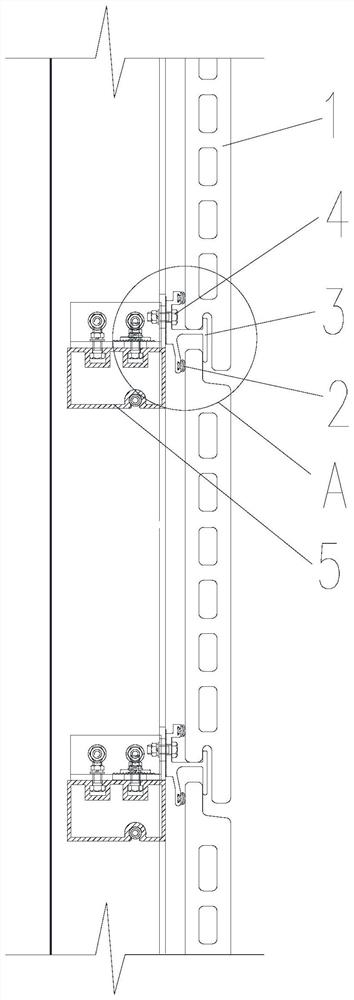

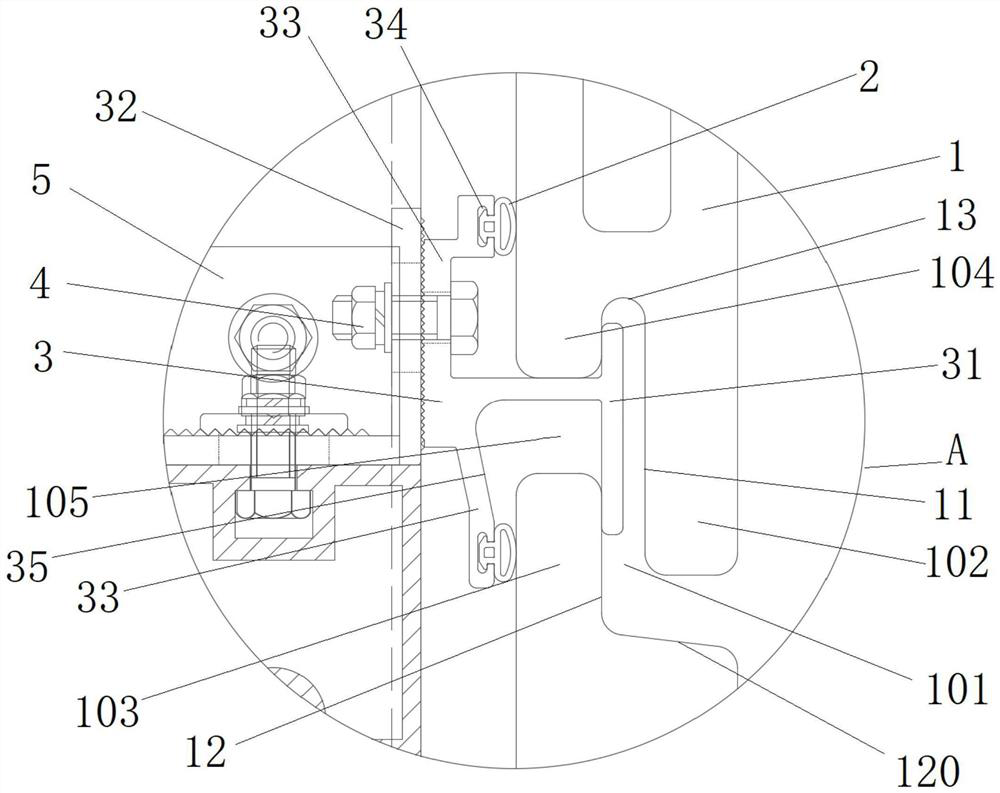

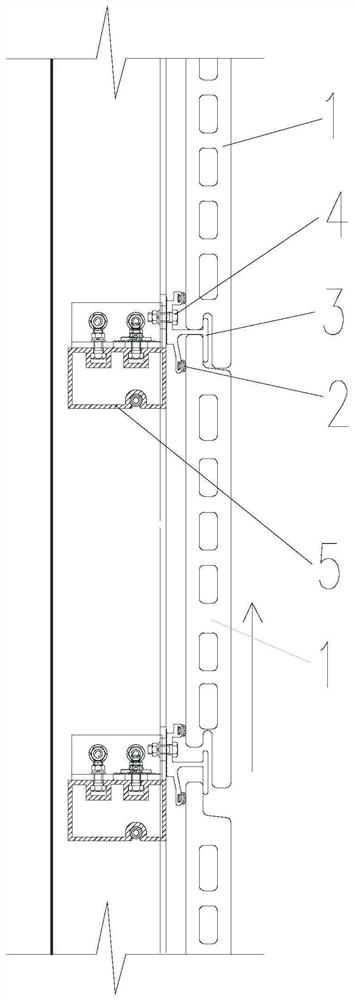

[0022] Please see attached figure 1 And attached figure 2 , an assembled ceramic aluminum sound-absorbing panel, including a sound-absorbing panel body 1, an air pad 2 and a buckle body 3; A second groove 12 is formed on the side, so that two adjacent sound-absorbing panel bodies 1 can be inserted and assembled through the first groove 11 and the second groove 12, and there is a gap between the assembly surfaces of the two sound-absorbing panel bodies 1. There is a first gap 101; one side of the buckle body 3 is formed with a first connecting portion 31, and the first connecting portion 31 can be mated and plugged into the first gap 101 between the assembly surfaces of two adjacent sound-absorbing panel bodies 1 up and down Inside, the top of the buckle main body 3 and the inner wall of the upper sound-absorbing panel body 1 are contacted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com