Welding tool for packaging marine catalyst module

A catalyst module and welding tooling technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of surface area reduction, carrier fragmentation, exhaust gas not meeting emission requirements, etc., to ensure catalytic efficiency, Easy to weld, tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

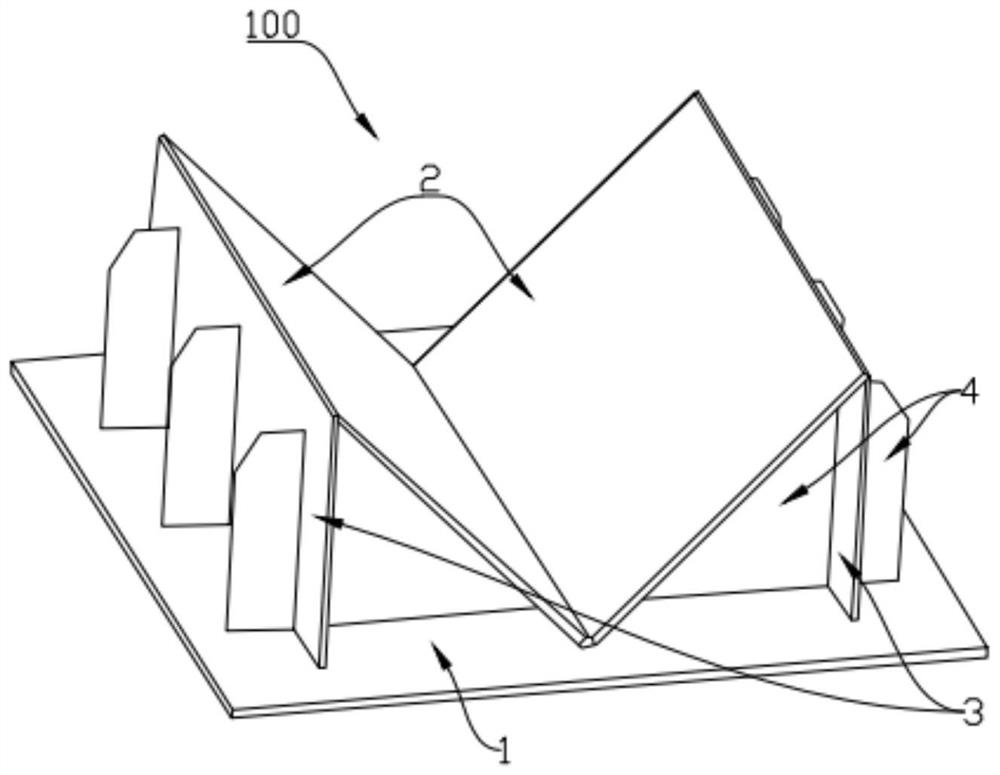

[0013] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings

[0014] In the ship engine exhaust system, the SCR reaction chamber is filled with a catalyst, and the reaction between the exhaust gas and urea (NH3) is accelerated under the catalysis of the catalyst. On the one hand, it improves the efficiency of exhaust gas treatment, and on the other hand, it also ensures the degree of exhaust gas treatment. The catalyst in the SCR reaction chamber is generally TiO 2 V for matrix carrier 2 o 5 and WoO 3 The mixture and the final catalyst generally have regular shapes and definite volumes, such as cylinders, cuboids, polygonal prisms and other shapes. Then with TiO 2 Catalysts used as carriers are prone to breakage and collapse during work, which reduces the surface area of the catalyst in contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com