Method for selectively matching face-to-face and back-to-back assembled bearing space rings by using pre-tightening force

A preload, back-to-back technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the gap between the preload and the expected preload, without considering the spacer shape and position tolerance and elastic deformation, spacer shape and position Tolerances and the gap between elastic deformation preload and expected preload, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 of the method of using pretightening force to select and match bearing spacers face to face in the present invention includes the following steps:

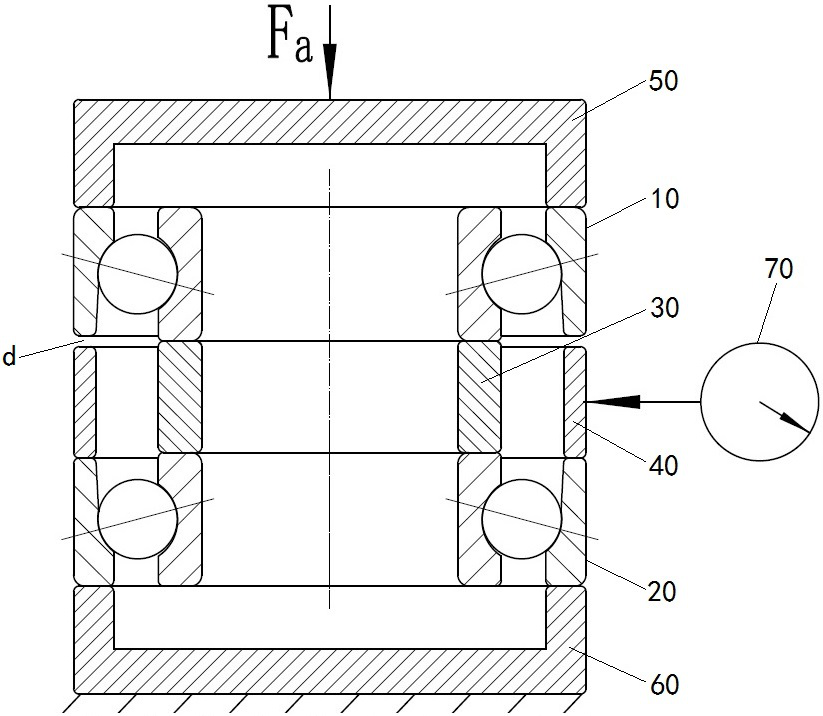

[0058] Step one, such as image 3 As shown, the inner spacer 30 and outer spacer 40 to be tested and the upper and lower sets of face-to-face bearings form a bearing assembly. with gap d. The outer ring of the lower end bearing (that is, the second bearing 20) is supported by a support 60 with a groove, thereby avoiding the inner ring of the second bearing 20; the first bearing is pressed by a gland 50 with a groove 10, so as to avoid the inner ring of the first bearing 10, apply downward axial pressure F to the gland 50 through the force application mechanism a , so that the outer ring of the first bearing 10 moves downward.

[0059] Step 2, gradually increase the axial pressure F a , when the axial pressure F a Reach the lower limit value F of the required preload of the bearing assembly 1 , use the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com