Installation method and hoisting method of hoisting system

An installation method and a technology of hoisting lugs, which are applied in the field of hoisting system installation and hoisting, to achieve the effects of reducing labor hours, avoiding potential safety hazards, and facilitating transportation and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

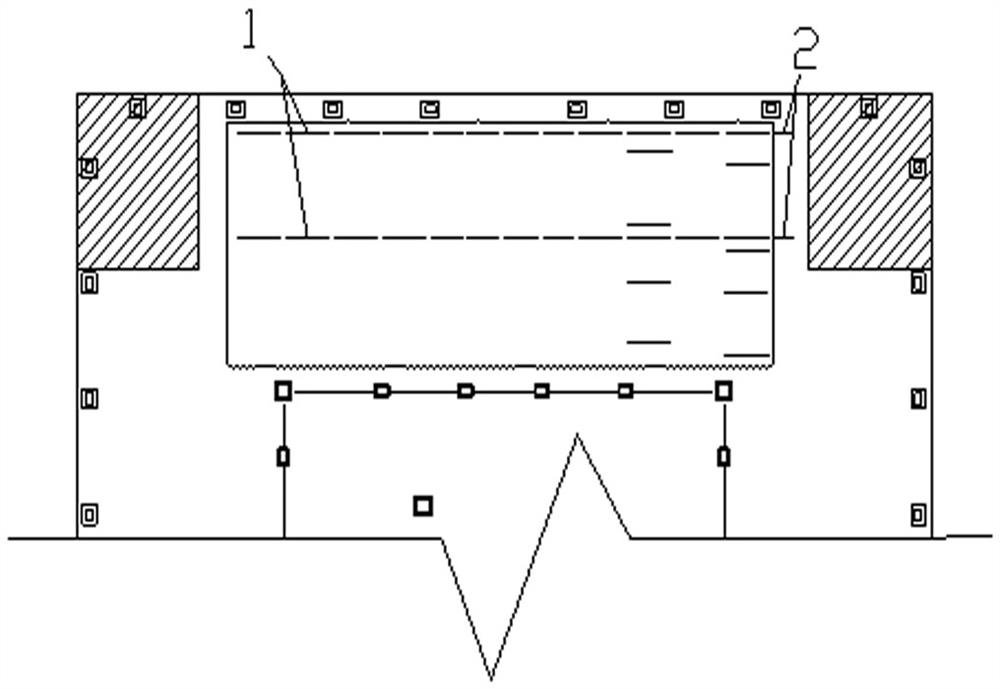

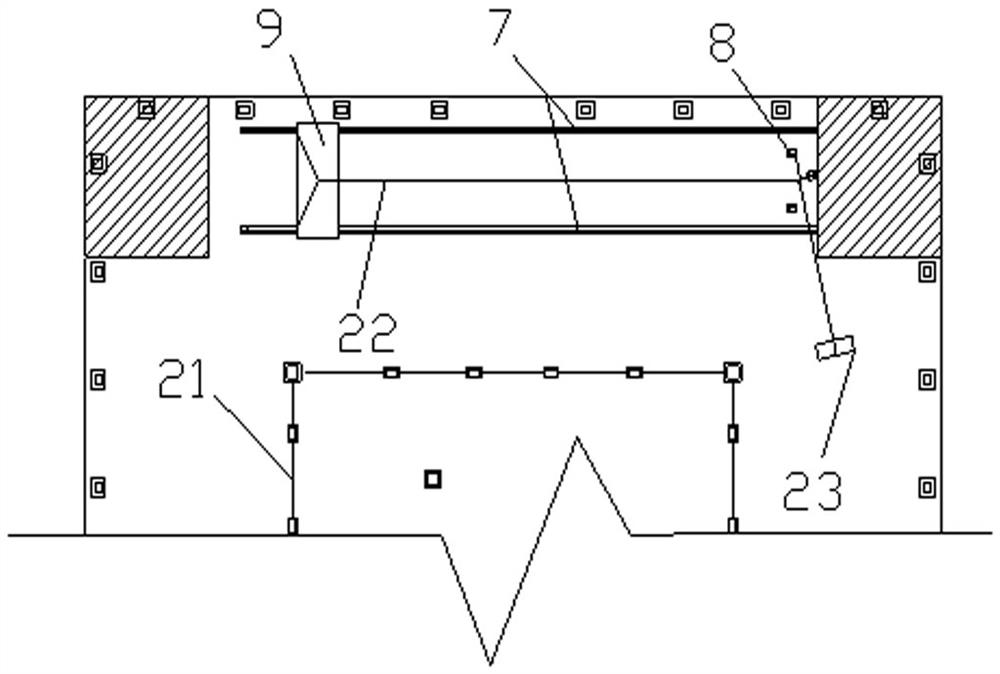

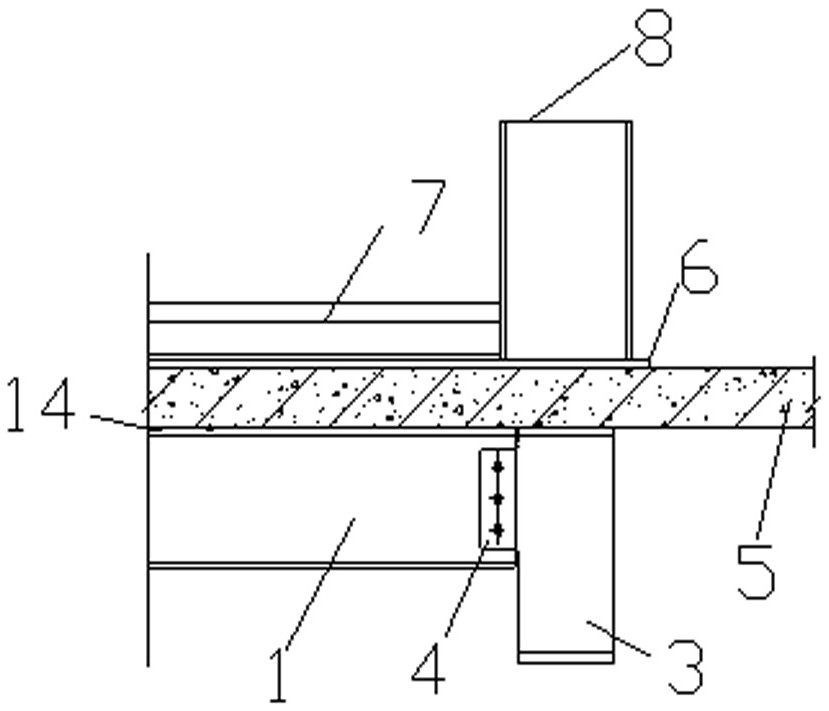

[0063] like Figure 1-13 As shown, the present invention provides a kind of hoisting system installation method and hoisting method, the present invention provides a kind of hoisting system installation method, has the following steps:

[0064] Step 1: Complete the construction drawings, and prefabricate steel beams in the factory according to the construction drawings; according to the calculation of the load capacity requirements of the horizontal transport unit to be installed and the hoisting and positioning unit, the first new steel beam 1, the second new steel beam 2 and the first new steel beam 2 should be added. The quantity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com