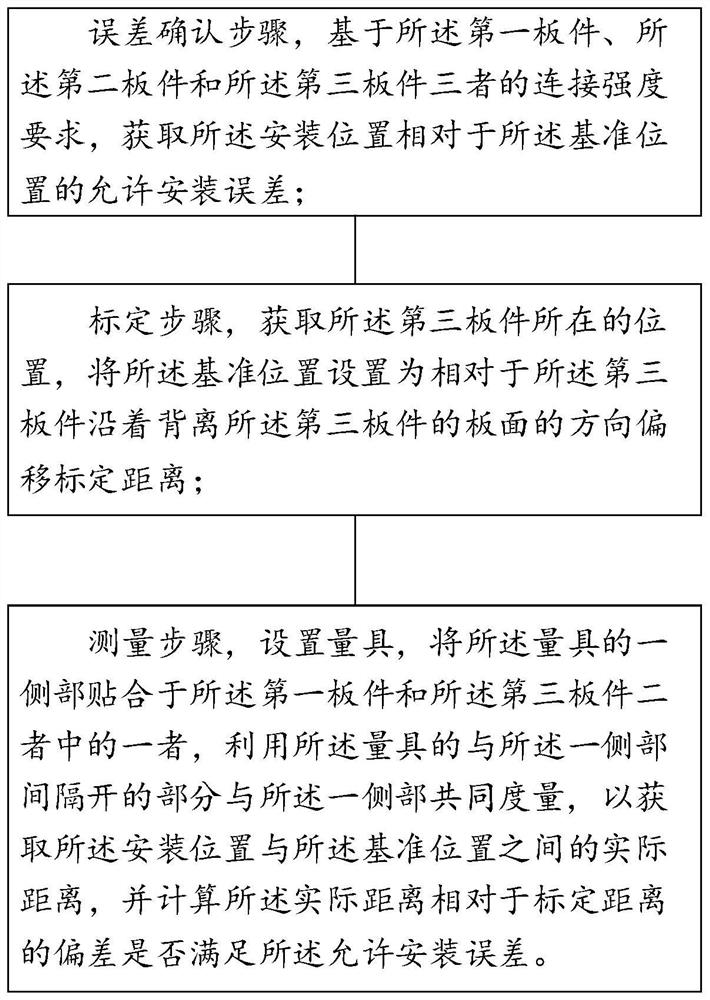

Measurement method

A measurement method and technology of measurement steps, applied in the field of measurement, can solve problems such as unfavorable installation errors and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

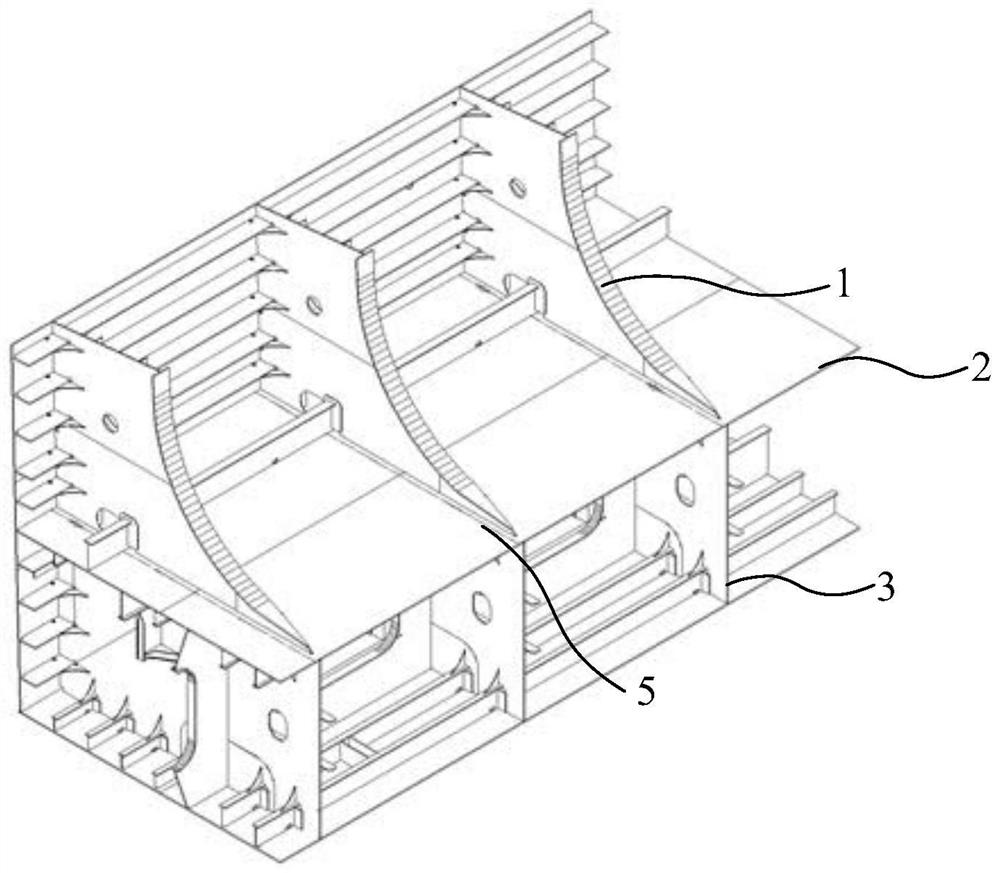

Image

Examples

Embodiment Construction

[0034] The following detailed description is provided to assist the reader in gaining an overall understanding of the methods, devices and / or systems described herein. However, various changes, modifications, and equivalents of the methods, apparatus, and / or systems described herein will be apparent upon understanding the disclosure of the present application. For example, the order of operations described herein is an example only and is not limited to the order set forth herein, but, except for operations that must occur in a particular order, can be made that will be apparent after understanding the disclosure of this application. change. Furthermore, descriptions of features that are known in the art may be omitted for increased clarity and conciseness.

[0035] The features described herein may be implemented in different forms and should not be construed as limited to the examples described herein. Rather, the examples described herein have been provided merely to illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com