Supporting vehicle locking mechanism

A car lock and locking screw technology, applied in vehicle parts, traction connectors, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, need, and lack of separation assistance, and achieve fast and convenient fixing and reliable separation assistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

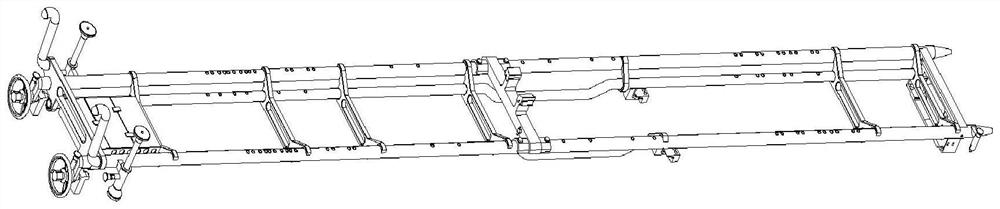

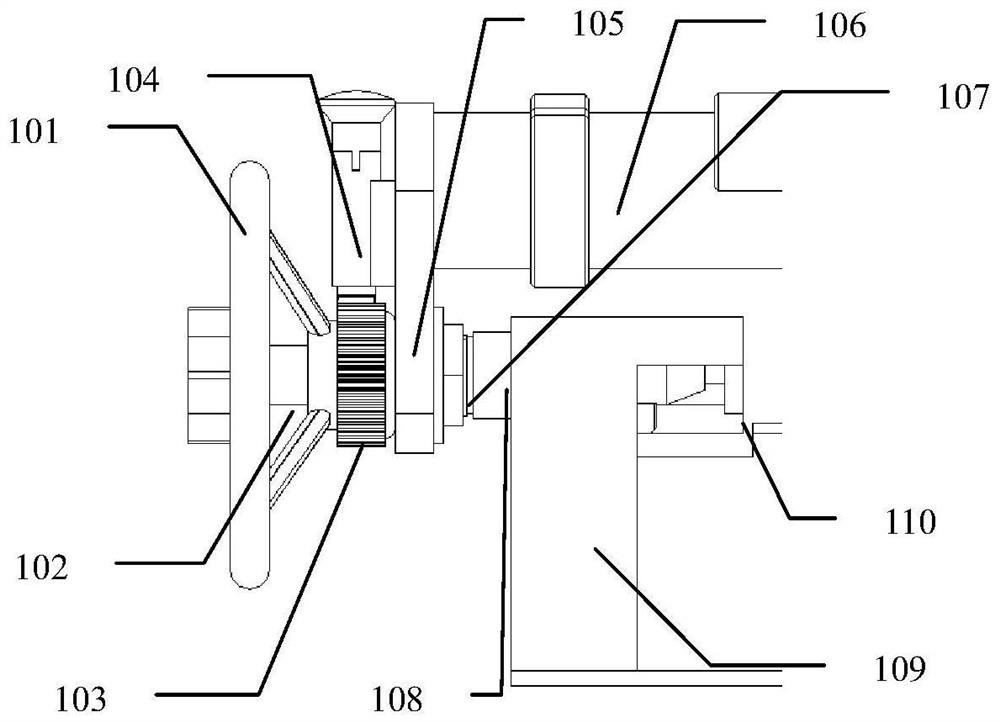

[0034] The present invention mainly provides a support car locking mechanism with separation power, including two parts: a front-end pre-tightening mechanism and a rear-end positioning mechanism. Safety device 104, mounting seat 105, vehicle beam 106, fixing nut 107, rubber pad 108, stop pile 109, stop pile side block 110 are composed of ten parts; the rear end positioning unit is fixed by the vehicle body positioning block 201 and the rear end The stopper 202 consists of two parts.

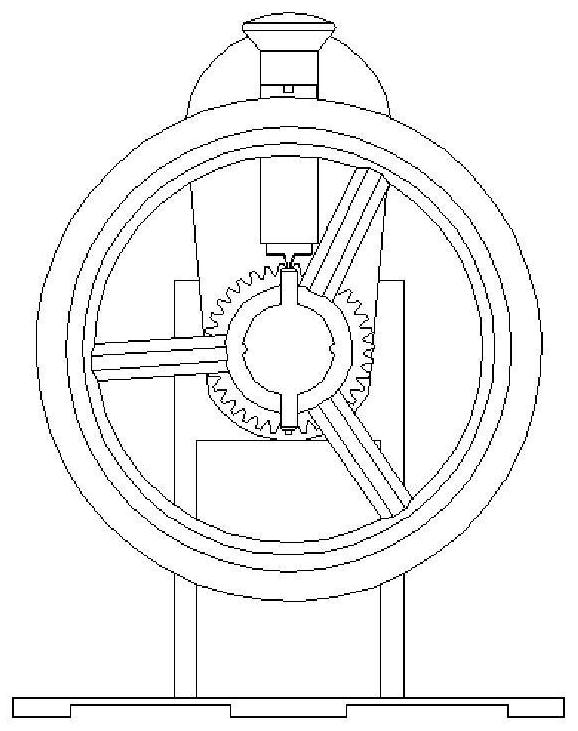

[0035] The rotary handle 101 and the ratchet screw sleeve 103 are integrally machined, and the outer ring of the ratchet screw sleeve 103 is provided with ratchet teeth. The ratchet screw sleeve 103 is installed on the mounting base 105 , and the ratchet screw sleeve 103 is fixed with a fixing nut 107 after passing through the mounting base 105 . The mounting seat 105 is welded on the vehicle beam 106 . The safety device 104 is installed directly above the ratchet screw sleeve 103, and the thim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com