A fixed position follow-up rigid support mechanism

A technology of rigid support and fixed position, which is applied in the direction of large fixed members, lifting devices, metal processing machinery parts, etc., and can solve problems such as safety accidents, poor support rigidity, and local structural displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

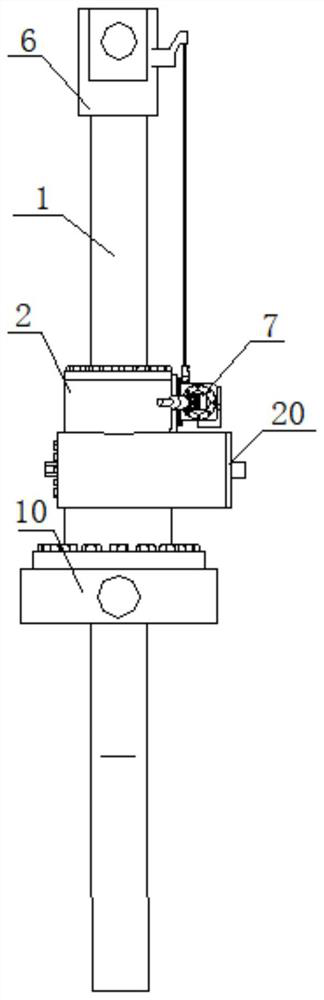

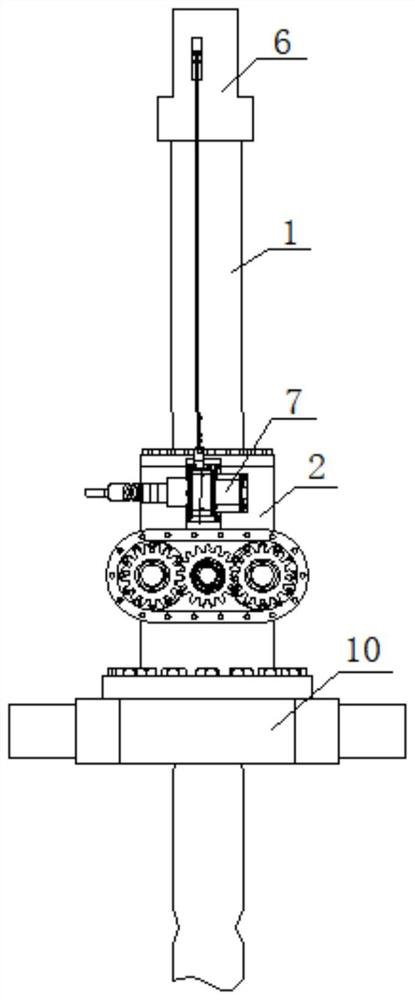

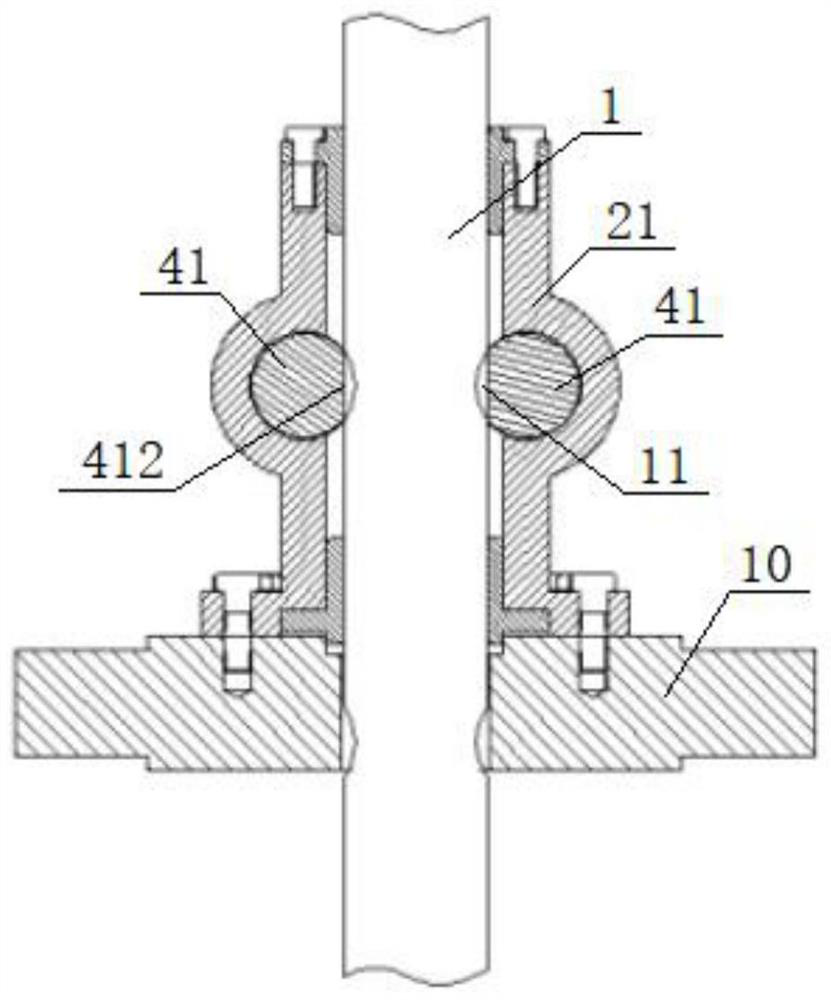

[0043] see Figure 1-Figure 7, a fixed position follow-up rigid support mechanism, comprising a follow-up rigid support rod 1, a lock 2, a connecting sleeve 6, a wire displacement sensor 7, and a mounting seat 10, the upper end of the follow-up rigid support rod 1 and the connecting sleeve 6 The bottom of the connecting sleeve 6 is fixedly connected, the upper end of the connecting sleeve 6 is provided with a through hole that is fixedly connected to the hinge shaft at the bottom of the support platform 8, and the lower end of the follow-up rigid support rod 1 passes through the locker 2 and the mounting seat 10 in turn and extends downward. , the bottom of the housing 21 of the locker 2 is fixedly connected to the drive cylinder support base 9 through the mounting seat 10 of the hinge-type structure. Two sets of locking shaft assemblies 4 on both sides, the drive shaft assembly 3 includes a horizontally arranged drive shaft 31 and a drive gear 32 set on it, one end of the dri...

Embodiment 2

[0045] The differences from the examples are:

[0046] A No. 1 guide sleeve 22 and a No. 2 guide sleeve 23 are respectively provided at the upper and lower end openings of the casing 21 . match.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com