Making process of quick-frozen fried rice noodles and quick-frozen fried rice noodles

A technology for making rice noodles, which is applied in food freezing, food science, food preservation, etc., can solve the problems of being unable to make quick-frozen fried rice noodles in batches, not having fresh rice noodles, and insufficient supply, so as to achieve easy assembly line operations and reduce Artificial loss and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation technology of quick-frozen fried rice noodles, the steps are as follows:

[0025] S1. Soak dried rice noodles at room temperature so that the moisture content is not lower than 40%;

[0026] Soak the dried rice noodles in water at room temperature for 4-6 hours, and take out when the water content is not lower than 40%;

[0027] S2. Preliminary aging and secondary increase of moisture content;

[0028] The soaked river noodles are preliminarily matured, and the preliminary ripening is boiled or soaked in boiling water, and boiled in boiling water for 4-6 minutes, so that the degree of ripening reaches 90%, and the water content of the rice noodles is increased to 65-75% %.

[0029] S3. Roll and knead seasoning;

[0030] Knead the preliminarily matured rice noodles and the heated cooking oil in a tumbler for 2-8 minutes;

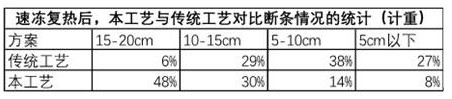

[0031] The specific tumbling time is adjusted according to the temperature and raw material conditions, the following table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com