Pipe network type humidifying system for refrigeration house

A humidification system and cold storage technology, which is used in household refrigeration devices, lighting and heating equipment, cooling fluid circulation devices, etc., can solve the problems of poor humidification uniformity, slow humidification speed, manual cleaning at regular intervals, etc. The effect of improving uniformity and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

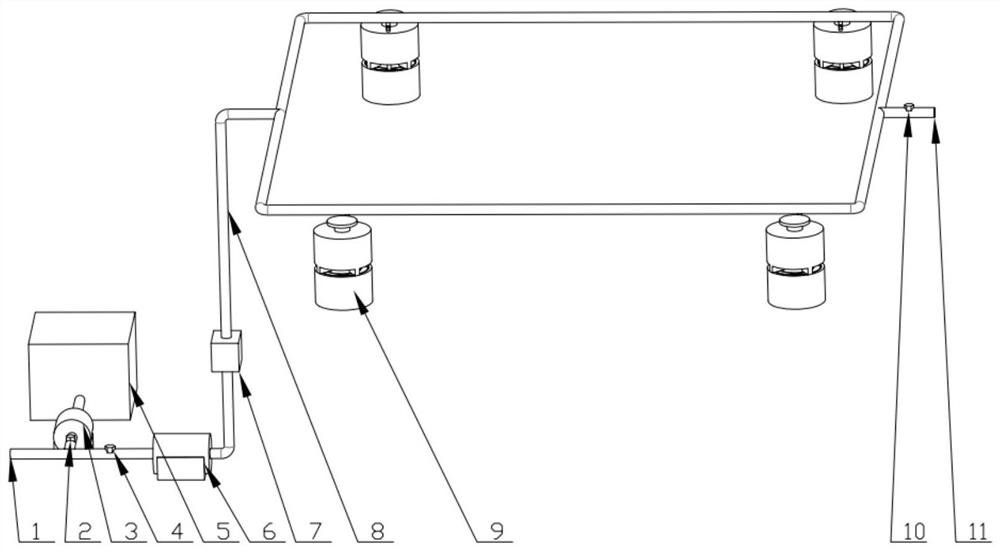

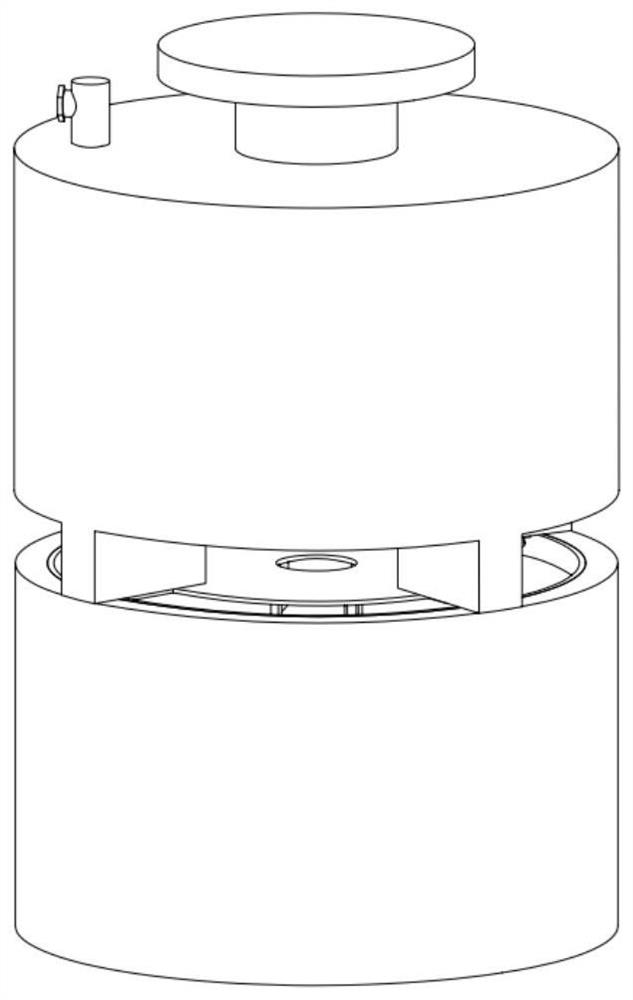

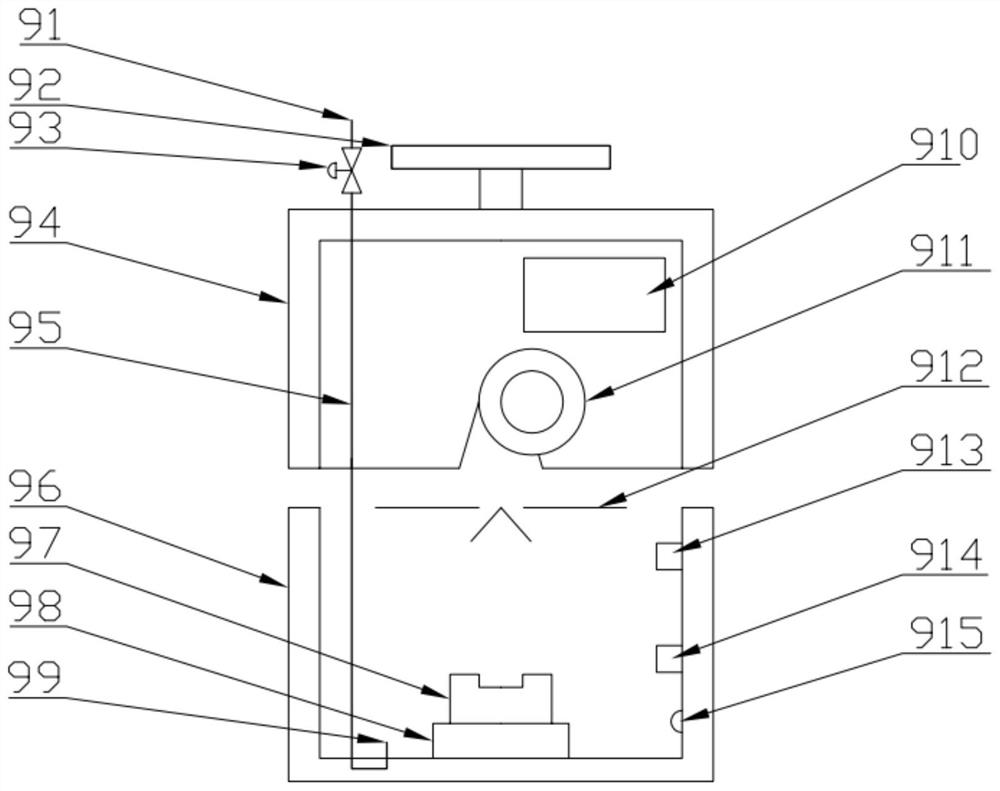

[0025] Example 1: See figure 1 , figure 2 , image 3 , Figure 4 , The present invention provides a technical solution: a cold storage pipe network humidification system. It is characterized in that it includes 1. Tap water inlet; 2. First solenoid valve; 3. Cleaning water pump; 4. Second solenoid valve; 5. Cleaning liquid tank; 6. Water pump; 7. Descaling device; 8. Main pipeline ; 9, humidification device; 10, the third solenoid valve; 11, sewage outlet; 91, water inlet; 92, ceiling installation device; 93, the fourth solenoid valve; 94, the top shell; Water box; 97, ultrasonic atomizing head; 98, heating device; 99, water outlet; 910, control circuit and communication module; 911, fan; 912, water deflector; 913, upper liquid level sensor; 914, lower Liquid level sensor; 915, temperature sensor; 9121, upper piece; 9122, lower piece; 9123, fixing hole.

[0026] When the present invention works, the humidity sensor distributed in the cold storage transmits signals to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com