Alcohol head polymerization purification preparation method

A technology of alcohol head and diethylene glycol, which is applied in the field of alcohol head polymerization, purification and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

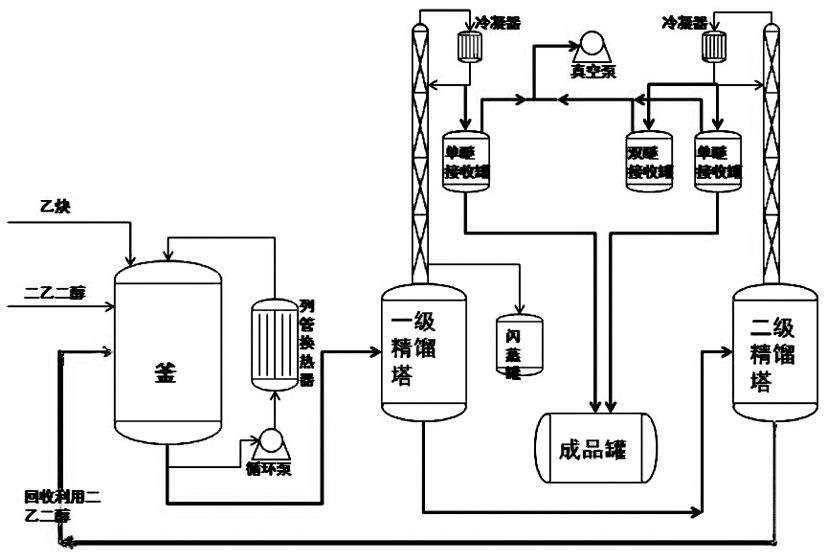

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] A kind of alcohol head polymerization purification preparation method, comprises the following steps:

[0030] (A) Add diethylene glycol and a prefabricated mixed solution of catalyst, polymerization inhibitor and stabilizer into the reactor.

[0031] The weight components of diethylene glycol, acetylene, and prefabricated mixed solution are as follows: 250-270 parts of diethylene glycol, 25-35 parts of acetylene, 8-9 parts of prefabricated mixed solution; preferably: 255-265 parts of diethylene glycol, 27 parts of acetylene -32 parts, 8.3-8.7 parts of prefabricated mixed solution.

[0032] In one embodiment, the weight components of diethylene glycol, acetylene, and prefabricated mixed solution are: 250 parts of diethylene glycol, 25 parts of acetylene, and 8 parts of prefabricated mixed solution; in one embodiment, diethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com