Transformer oil static pressure device and transformer system

A technology for transformer oil and transformers, applied in the field of transformers, can solve the problems of high cost, not allowing the design of hanging tanks, affecting the normal production of transformers, etc., to meet the requirements of oil static pressure, and to achieve the effects of convenient and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

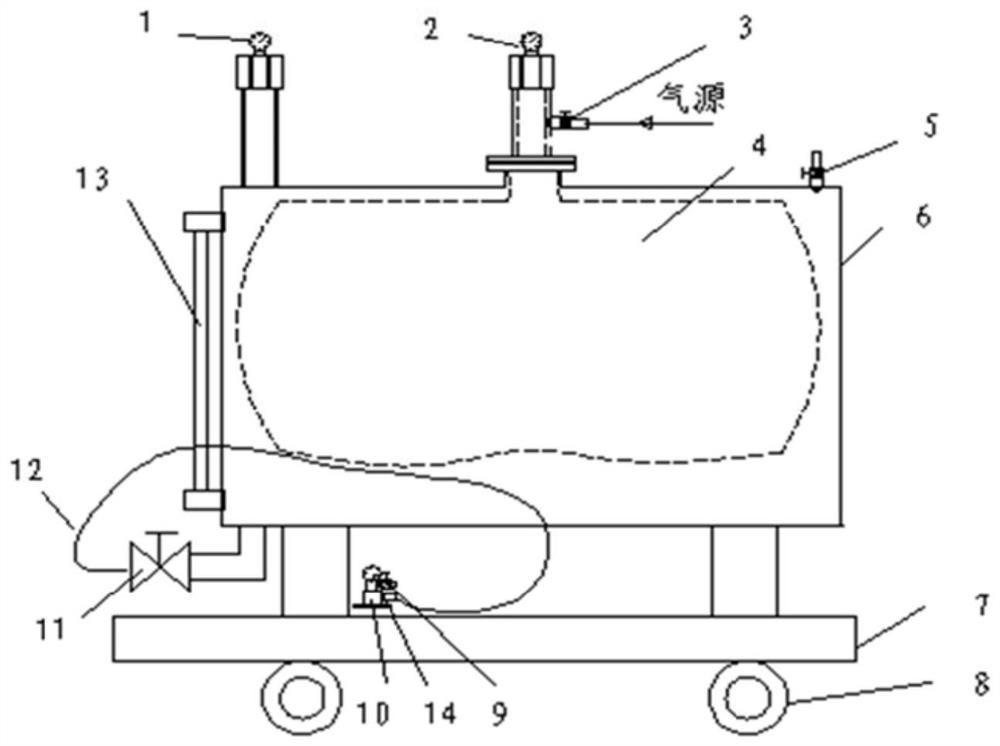

[0043] like figure 1 As shown, this embodiment discloses a transformer oil static pressure device, which includes a base 7 and a housing 6 arranged on the base 7 . The casing 6 is provided with an air charging port and a test interface.

[0044] There is an air bag 4 suspended in the housing 6, the inner cavity of the housing is completely isolated from the inside of the air bag, and the inflation port communicates with the interior of the air bag 4. The inflation port is provided with a first valve 3, and the first valve 3 is used to control the opening of the inflation port. close. When the first valve 3 controls the opening of the inflation port, compressed gas can be filled into the airbag 4 through the inflation port. cavity volume.

[0045] The test interface is used to connect with the main body of the transformer, and a second valve 11 is provided at the position of the test interface, and the second valve 11 is used to control the opening and closing of the test in...

Embodiment 2

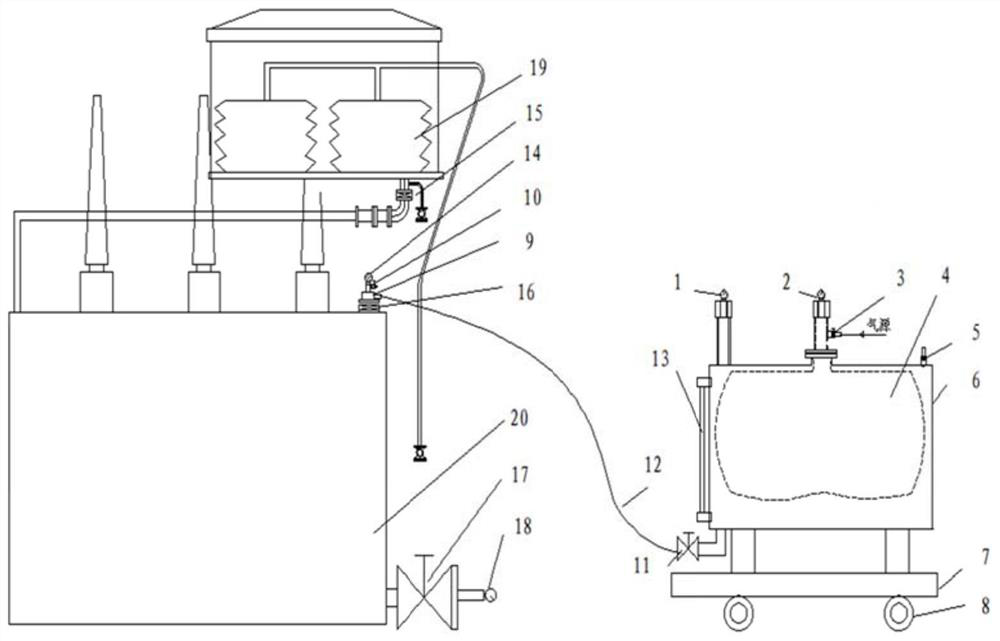

[0062] like figure 2 As shown, the present embodiment provides a transformer system, including a transformer main body 20, and the transformer oil static pressure device in Embodiment 1, wherein, there is an 80 butterfly valve 16 on the transformer main body, and the test interface in the transformer oil static pressure device is connected to the 80 Butterfly valve 16 communicates. Specifically, the transformer oil static pressure device is connected as a whole with the transformer main body 20 through the L-shaped joint at the end of the pressure-resistant tube.

[0063] The oil static pressure process using the oil static pressure device is as follows:

[0064] 1. Close the main pipe valve 15 connected between the oil conservator 19 of the transformer and the main body 20 of the transformer, install a bottom pressure gauge 18 at the end of the oil filling and draining valve 17, and connect the pressure-resistant pipe 12 of the static pressure device The L-shaped joint 9 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com