Energy-saving enthalpy difference laboratory heat exchange system capable of switching modes

A technology for switching modes and heat exchange systems, which is applied to compressors with reversible cycles, lighting and heating equipment, evaporators/condensers, etc. Quantity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

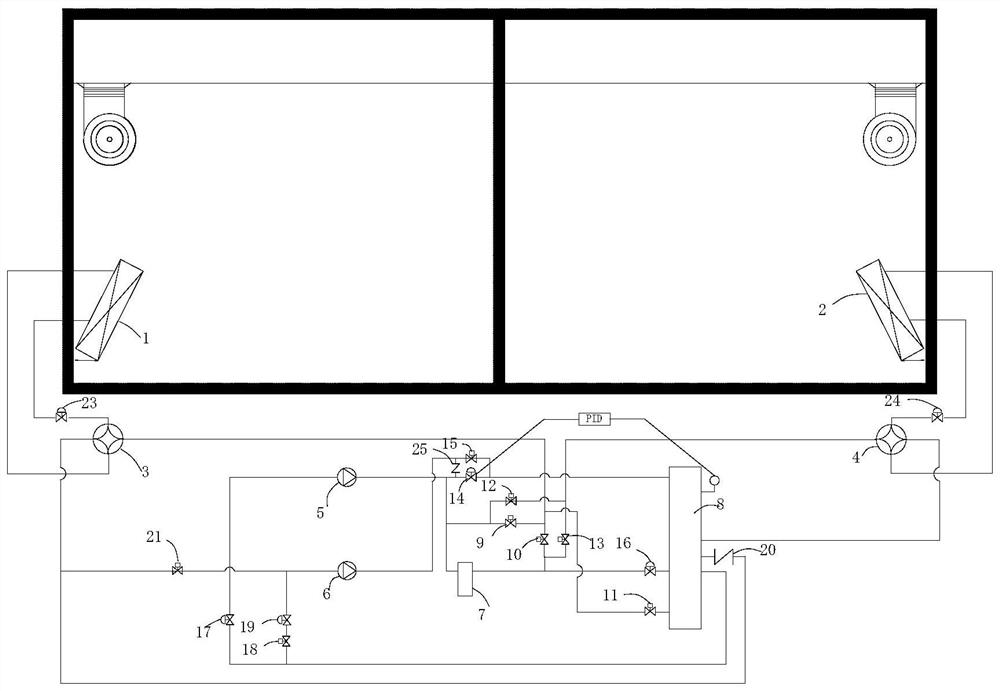

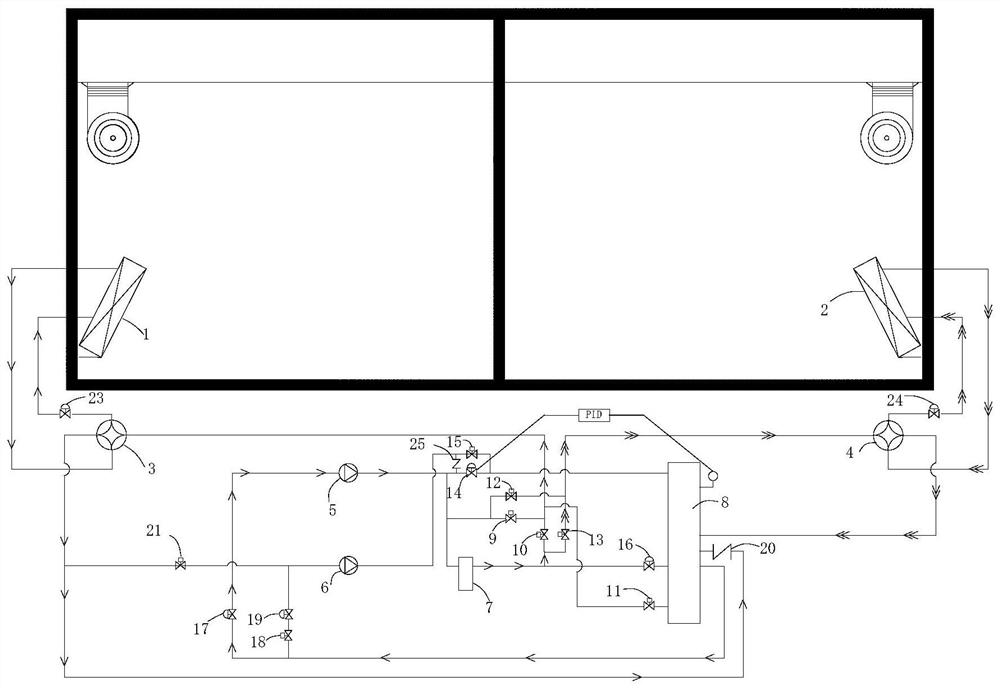

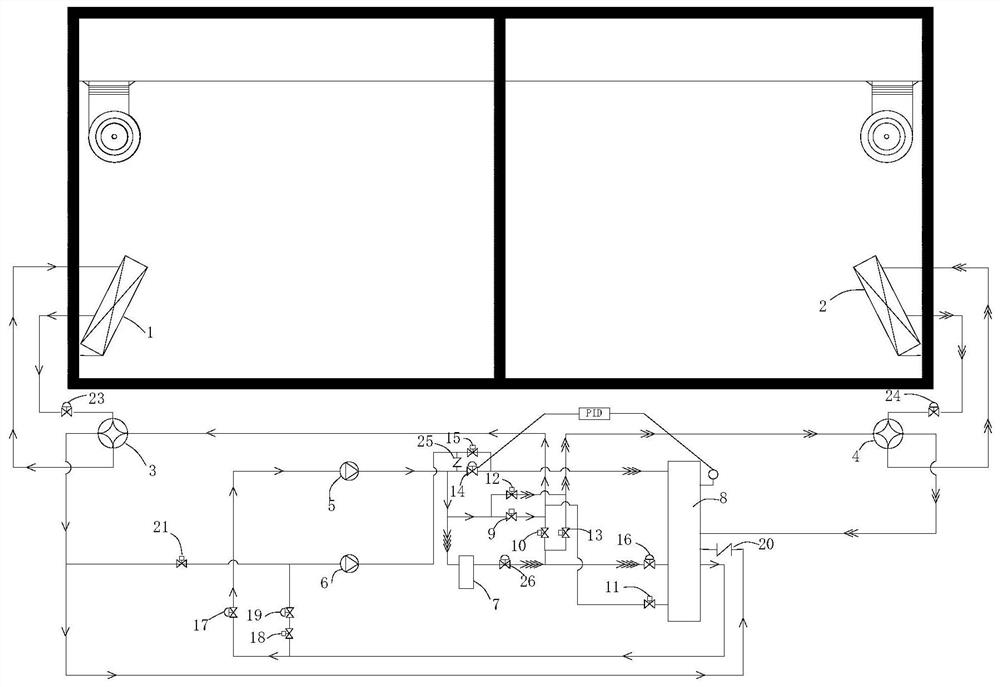

[0044] figure 1 It is a schematic diagram of the overall structure of the energy-saving enthalpy difference laboratory heat exchange system with switchable modes in the present invention.

[0045] Such as figure 1 As shown, a switchable energy-saving enthalpy difference laboratory heat exchange system includes a first heat exchanger 1, a second heat exchanger 2, a first switch assembly, a second switch assembly, a third switch assembly, and a first switch assembly. Four switch assemblies, the first compressor 5, the second compressor 6, the condenser 7, the pressure regulating assembly and the fluorine barrel 8, wherein: the first compressor 5, the condenser 7 and the fluorine barrel 8 are connected in sequence to form a first cycle, The second compressor 6, the condenser 7 and the fluorine barrel 8 are circularly connected in turn to form the second cycle, both the first cycle and the second cycle can be used for the refrigerant condensation cycle, and the fluorine barrel 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com