Pure pneumatic control automatic sprue cutting mold

A gating and automatic technology, applied in the direction of metal processing, etc., can solve the problems of unstable degating quality, high cost, large human resources and labor, etc., achieve control of labor costs and production costs, simple structure, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

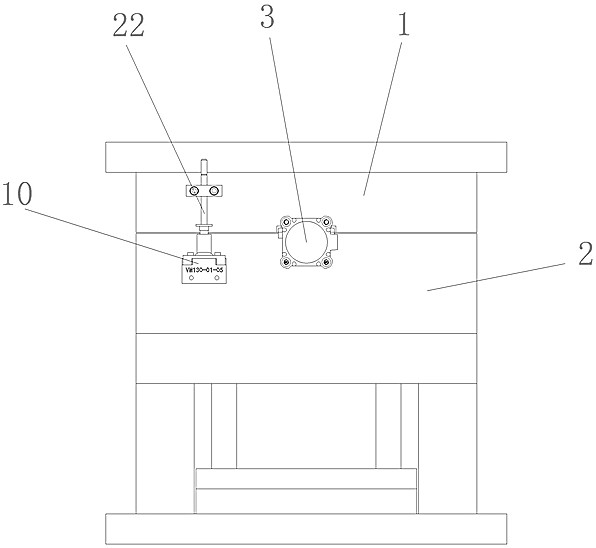

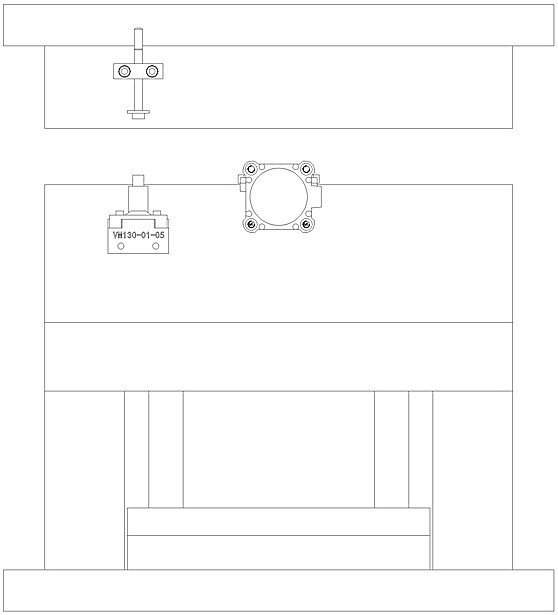

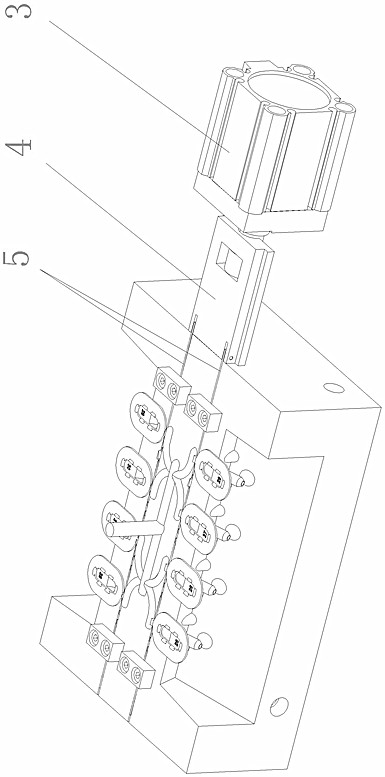

[0021] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 11 Shown: a pure air-controlled automatic gate cutting mold, including a fixed mold part 1 and a movable mold part 2 that match each other, and the fixed mold part 1 and the movable mold part 2 are respectively provided with a fixed mold core and a movable mold core, The fixed mold core and the movable mold core are closed to form a mold cavity in the mold closing state, and a gate cutting cylinder 3 is arranged in the movable mold part 2, and the working end of the gate cutting cylinder 3 is connected with the slider seat 4, and the slider seat 4 is connected with two symmetrically distributed strip sliders 5, and the strip sliders 5 are slidably connected in the slideway opened on the movable mold core, and a plurality of cutting knives 6 are arranged on the strip slider 5 , the cutter 6 matches the quantity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com