Bipolar plate for all-vanadium redox flow battery based on butadiene styrene rubber and preparation method of bipolar plate

An all-vanadium redox flow battery, styrene-butadiene rubber technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of poor mechanical properties of materials, high graphite filling amount, etc., to achieve good flexibility, uniform dispersion, favorable for The effect of overall cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 70 parts of expanded graphite and 2 parts of sulfur were mixed for 10 minutes by a high-speed mixer, and then mixed with 30 parts of styrene-butadiene rubber raw rubber at 70°C until uniform. The rubber compound after being milled was taken into a mold, and was molded by hot pressing at a temperature of 150° C. and a pressure of 20 MPa for 30 minutes to obtain a bipolar plate.

[0022] The bipolar plate had a resistivity of 12 mΩ·cm, a bending strength of 23 MPa, and an elongation at break of 34%.

Embodiment 2

[0024] Take 60 parts of expanded graphite and 3 parts of sulfur to mix for 10 minutes through a high-speed mixer, and then knead with 40 parts of styrene-butadiene rubber raw rubber at 65°C until uniform. The rubber compound after being milled was taken into a mold, and hot-pressed for 25 minutes at a temperature of 160° C. and a pressure of 15 MPa to obtain a bipolar plate.

[0025] The bipolar plate had a resistivity of 41 mΩ·cm, a bending strength of 26 MPa, and an elongation at break of 51%.

Embodiment 3

[0027] 50 parts of expanded graphite and 5 parts of sulfur were mixed for 10 minutes by a high-speed mixer, and then mixed with 50 parts of styrene-butadiene rubber raw rubber at 60°C until uniform. The rubber compound after being milled was taken into a mold, and hot-pressed for 15 minutes at a temperature of 170° C. and a pressure of 10 MPa to obtain a bipolar plate.

[0028] The bipolar plate had a resistivity of 103 mΩ·cm and a bending strength of 31 MPa.

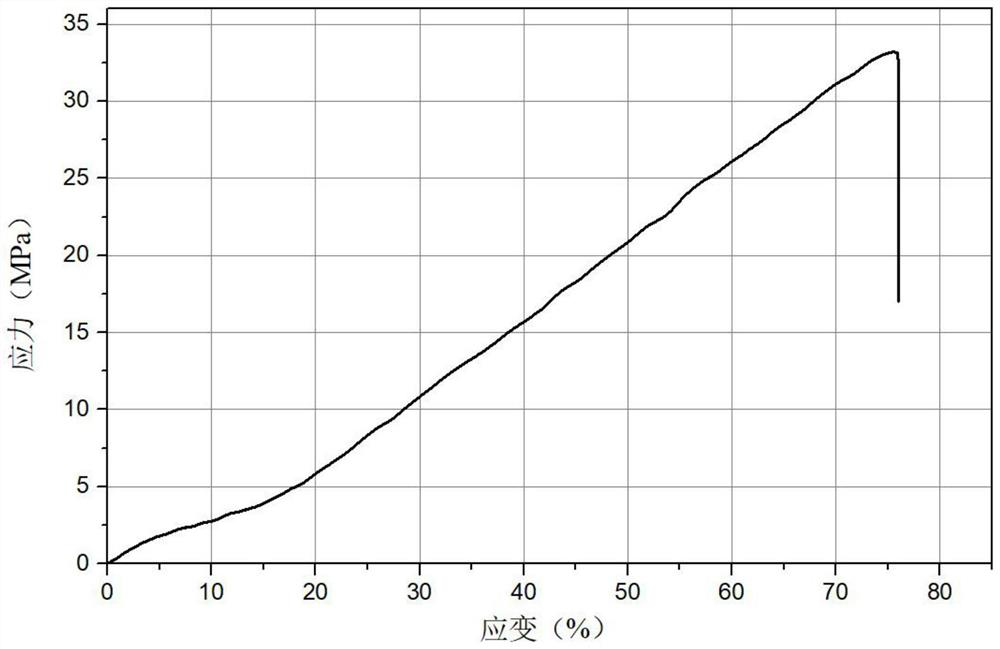

[0029] figure 1 The tensile curve of the sample prepared in Example 3 reflects the relationship between the strain of the sample and the stress, and it can be found that the elongation at break is 76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com