Modularized fabricated building

A modular and prefabricated technology, used in buildings, building components, building structures, etc., can solve the problems of same-layer connection and upper and lower connection troubles, general economic benefits and practicability, and general stability, and achieve good stability. , Good economic benefits, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

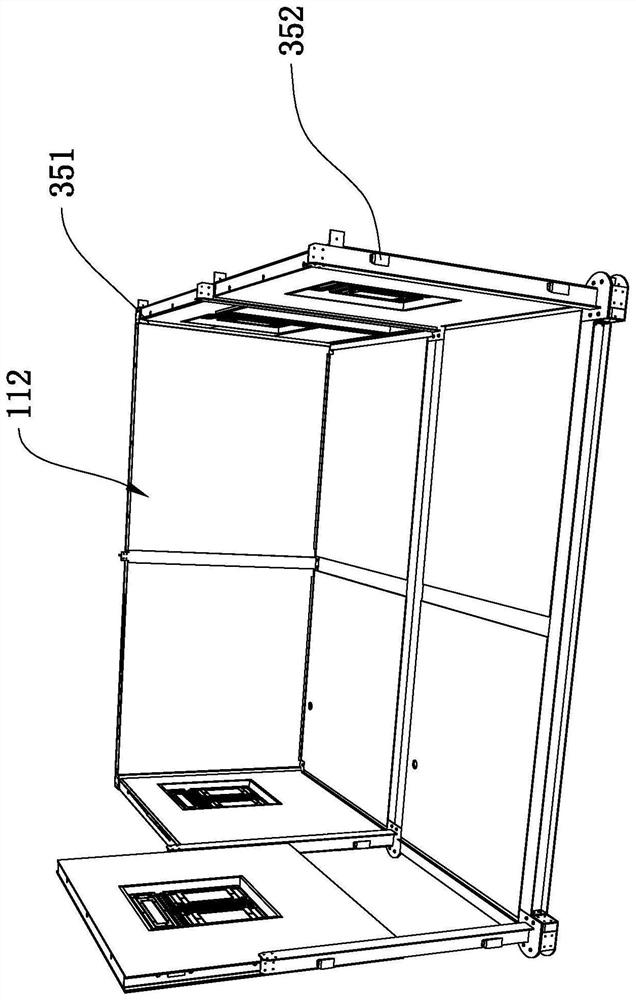

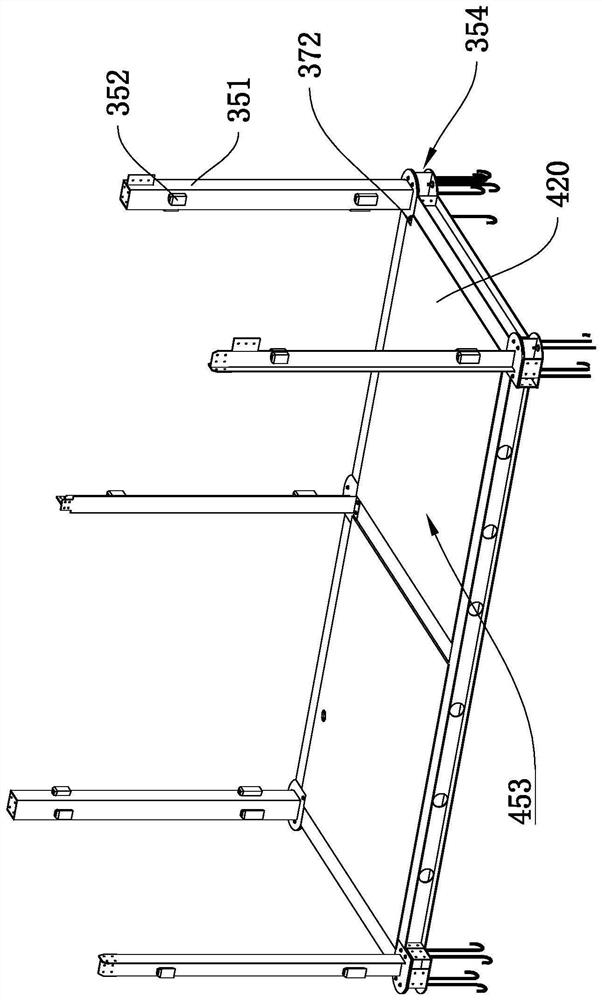

[0054] Such as Figure 1-19 As shown, a modular prefabricated building includes several modular walls 112 and corner columns 351 connecting two adjacent modular walls 112, and the adjacent two sides of the corner columns 351 are respectively provided with first limiting Position component 352, the side end of the modular wall 112 is provided with a second limit component 353 that is limited and matched with the first limit component 352 in the horizontal direction, and the bottom end of the corner column 351 is connected with a corner base 354 The adjacent two sides of the corner base 354 respectively have a floor installation part 356 connected with the modular floor assembly 453, and a horizontal beam 1000 is arranged above the modular floor assembly 453, and floor installation parts are arranged on both sides of the horizontal beam 1000. Groove 1001, the modular floor assembly 453 is inserted into the floor installation groove 1001, the modular floor assembly 453 is laid se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com