Combined metal inhaul cable rigging

A combined, metal technology, applied in the field of rigging, can solve problems such as decoupling, goods falling off the rigging, etc., to save time, reduce workload, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

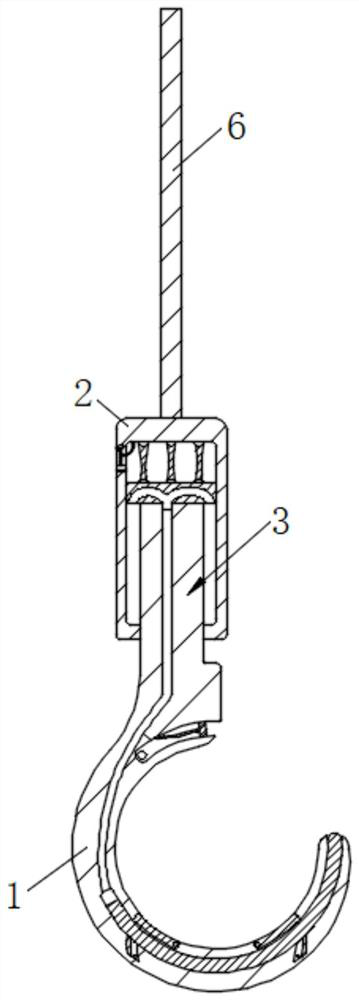

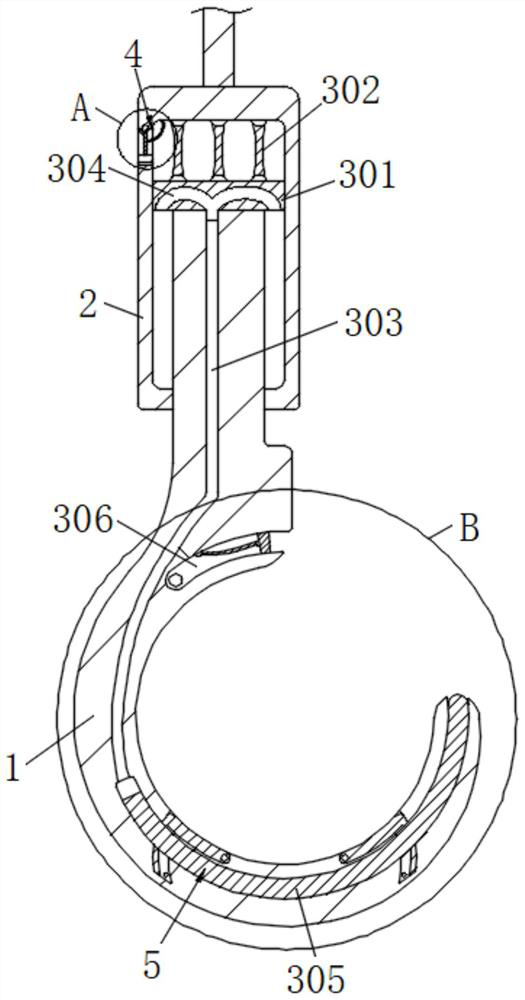

[0023] see Figure 1-5 , the present invention provides a technical solution: a combined metal cable sling, including a cable 6, the bottom of the cable 6 is fixedly connected with a fixed block 2, the inner wall of the fixed block 2 is provided with a hook cable 1, and the inside of the hook cable 1 is provided with a Automatic closing mechanism 3;

[0024] The automatic closing mechanism 3 includes a lifting block 301 and an elastic rope 302. The pulling force of the elastic rope 302 is far greater than the gravity of the lifting block 301 and the hook rope 1, an air groove 303 and an air inlet groove 304, and the inside of the air inlet groove 304 communicates with the inside of the air groove 303. , arc-shaped plate 305, slot 306, the outer wall of the lifting block 301 is slidingly connected to the inner wall of the fixed block 2, the top of the lifting block 301 is fixedly connected to one end of the elastic rope 302, the other end of the elastic rope 302 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com