Multi-working-condition automatic speed regulation control system of electric loader

A technology of automatic speed regulation and control system, which is applied in the direction of control drive, control device, electric vehicle, etc. It can solve the problems of electric loader speed limit, high energy consumption, poor driver experience, etc., to extend the charging interval and ensure operation safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

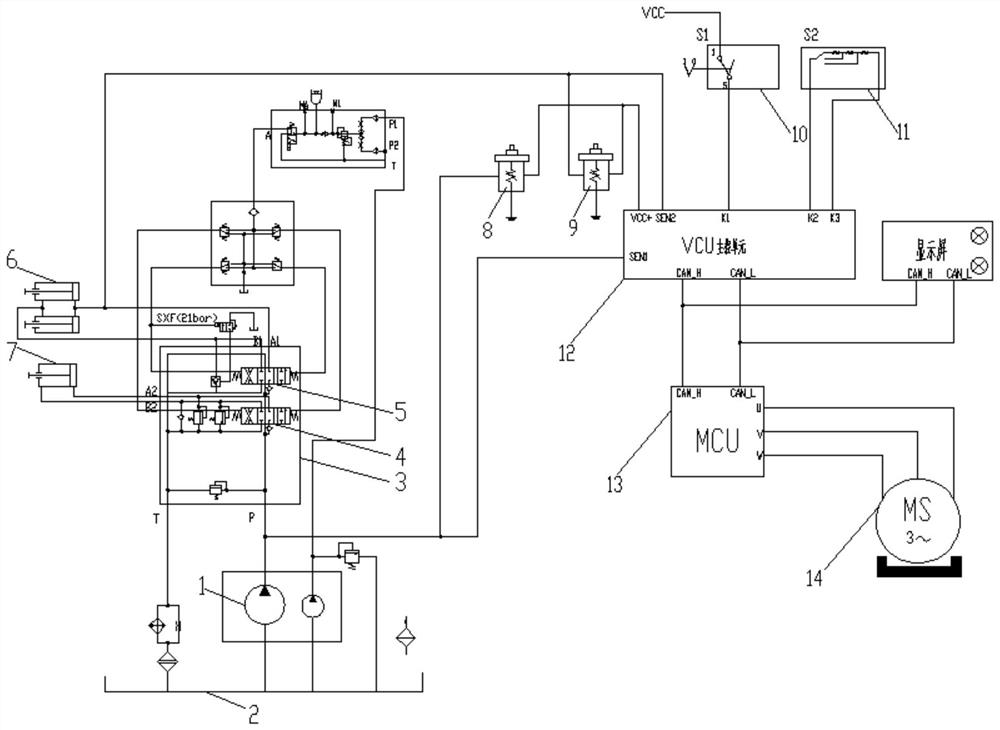

Method used

Image

Examples

Embodiment 1

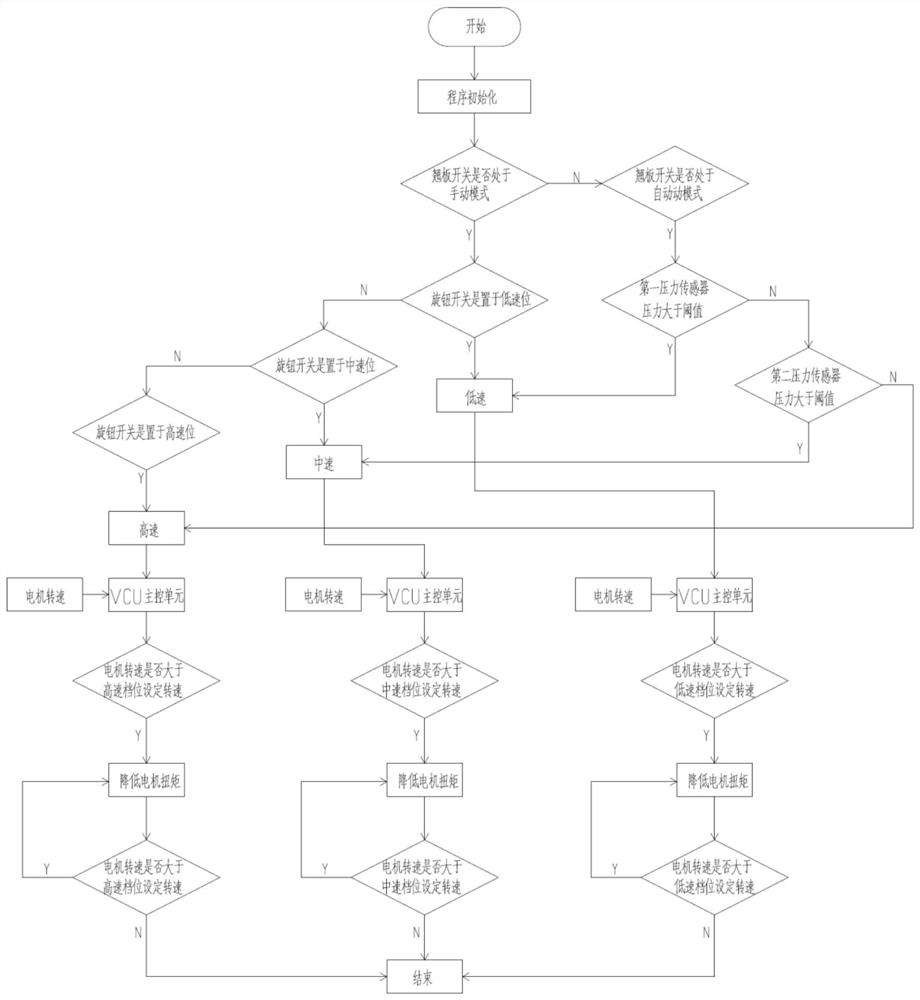

[0044] The rocker switch 10 is in the manual mode, which is the default mode of the loader. The driver can manually turn on the shift function according to his own functional requirements, specifically:

[0045] Rotate the rotary switch 11 to the gear corresponding to the low-speed driving of the loader. After the determination of the control strategy, the VCU control unit 12 outputs the speed limit execution parameter corresponding to the gear, and transmits it to the motor controller 13 through CAN communication. At the same time, the motor The controller 13 reads the speed of the travel motor 14, compares the current speed with the set value of the gear, and controls the output torque of the travel motor 14 so that the travel motor 14 maintains the maximum speed limit of the gear. Similarly, the rotary switch 11 is rotated to the loader The high-speed or medium-speed gear can realize the high-speed or medium-speed driving of the loader.

[0046] The high-speed driving gear ...

Embodiment 2

[0048] The rocker switch 10 is in the automatic mode, which sets the pressure threshold of the pump port of the working pump 1 when the working tool is not in action, and sets the pressure threshold of the large cavity of the boom cylinder 6 when the loader tool is lifted at the highest position without load; automatically The speed regulation specifically includes the following steps: (1) When the pressure value detected by the first pressure sensor 8 is greater than the pressure threshold of the pump port of the working pump 1, the VCU control unit 12 judges that the loader is in the shoveling condition, and controls the speed of the loader Do not exceed the maximum speed in the low drive gear;

[0049] That is, when the boom cylinder 6 or the bucket cylinder 7 is in a moving state, the multi-way valve spool I 3 or the multi-way valve spool II4 is in the working position under the promotion of the pilot oil. At this time, the high-pressure oil of the working pump 1 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com