Flaxseed oil pressing device

A linseed oil and rolling technology, applied in presses, fat oil/fat production, fat oil/fat refining, etc., can solve problems affecting oil filtration, filter hole blockage, lack of cleaning components, etc., to improve efficiency and prevent processing Efficiency, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

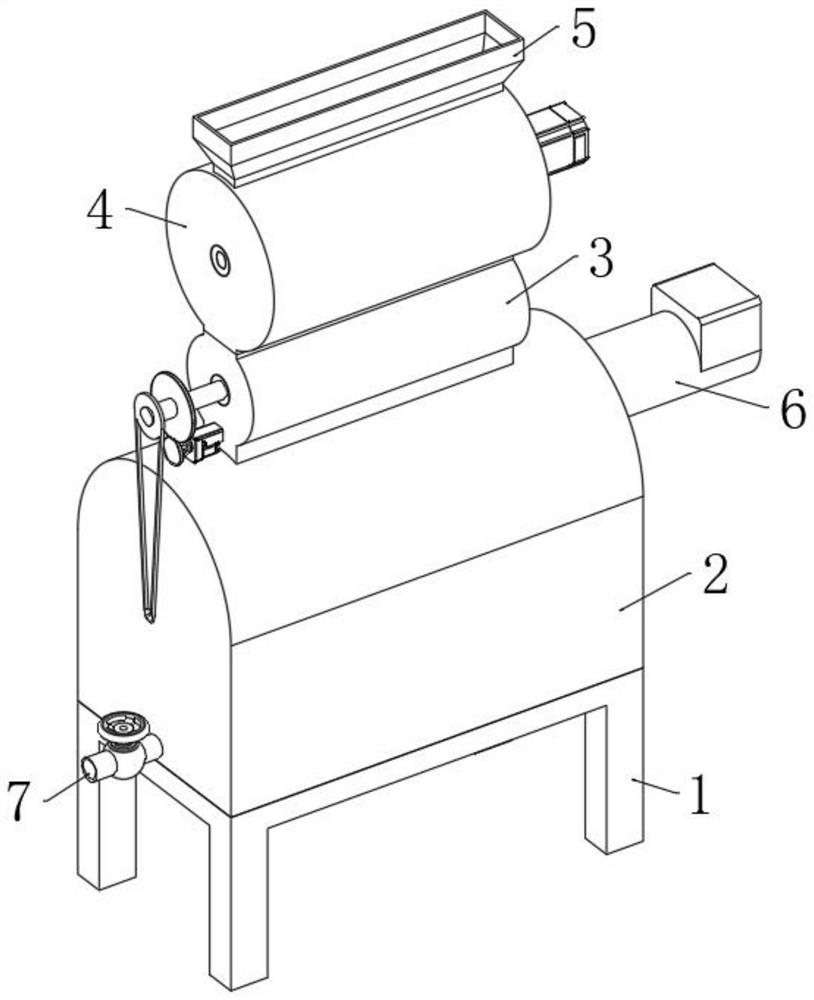

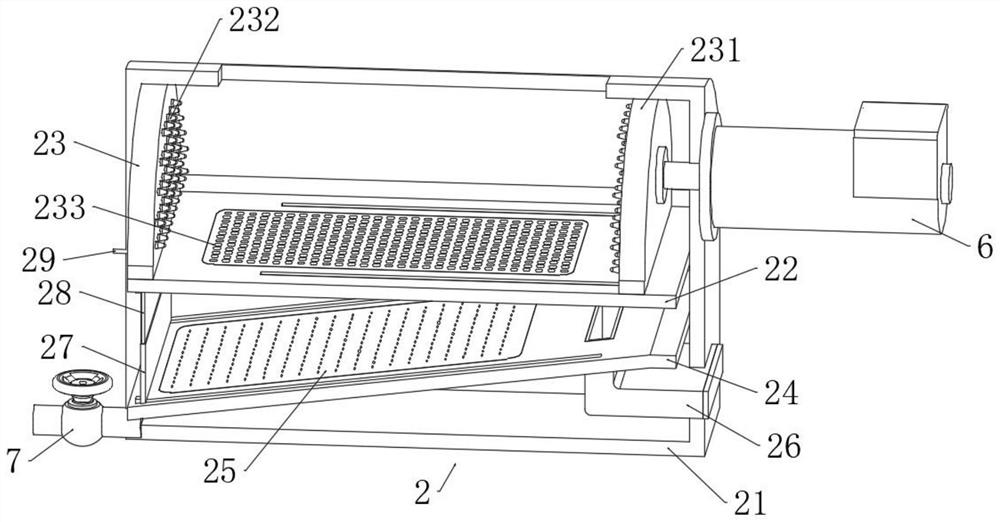

[0033] Example: such as Figure 1-Figure 8 As shown, the present invention provides a linseed oil rolling device, including a bottom frame 1, a rolling filter mechanism 2 is fixedly installed on the top of the bottom frame 1, and a rolling filter mechanism 2 is fixedly mounted on the top of the rolling filter mechanism 2. A material control component 3, the top of the control component 3 is fixedly equipped with a pretreatment component 4, the top of the pretreatment component 4 is fixedly clamped with a feeding frame 5, and the upper end of one side of the rolling filter mechanism 2 is fixed A power mechanism 6 is installed, and an oil control valve 7 is fixedly clamped at the lower end of the pressing filter mechanism 2 away from the power mechanism 6 .

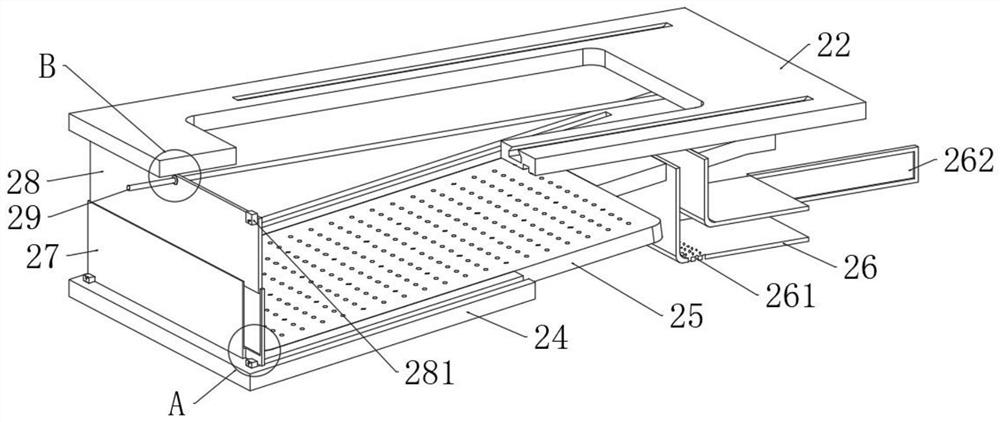

[0034] The pressure rolling filter mechanism 2 includes a slow oil frame 21, the bottom end of the slow oil frame 21 is fixedly installed on the top of the chassis 1, the power mechanism 6 is fixedly installed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com