An energy storage workover rig

A technology of workover rig and energy storage mechanism, which is applied in the direction of mechanical equipment, drilling equipment, electromechanical devices, etc., which can solve the problems of high energy consumption and achieve the effects of long service life, good stability and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

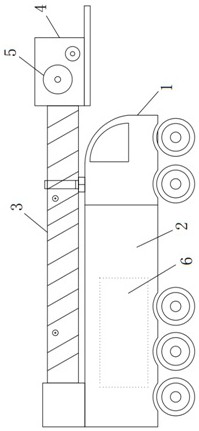

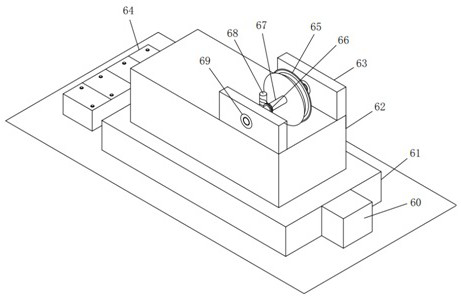

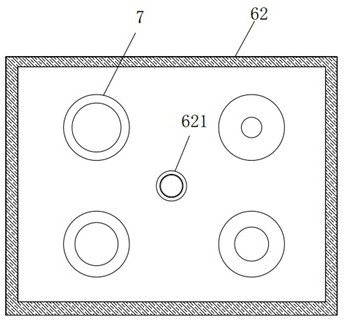

[0043] Such as Figure 1-Figure 9As shown, an energy storage workover rig according to an embodiment of the present invention includes an energy storage mechanism 6 fixedly installed inside the compartment 2 of the workover rig body 1, and the energy storage mechanism 6 includes Gear transmission box 61, energy storage box 62 and power mechanism, described power mechanism is fixedly installed on the top of described energy storage box 62, and described power mechanism comprises vertical plate 63, and described vertical plate 63 is provided with two groups, and two The group vertical plate 63 is fixedly connected to one end of the top of the energy storage box 62, and a rotating shaft 67 is installed between the two groups of vertical plates 63 through a supporting bearing 69, and a winding rope wheel is fixedly installed on the rotating shaft 67. 65, and a worm wheel 66 is installed on the rotating shaft 67, a sealed bearing 621 is fixedly installed on the inner bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com