Fuzzy PID temperature adjusting method for steel billet reheating in strip steel hot continuous rolling production

A temperature regulation, hot continuous rolling technology, used in temperature control, geometric CAD, complex mathematical operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

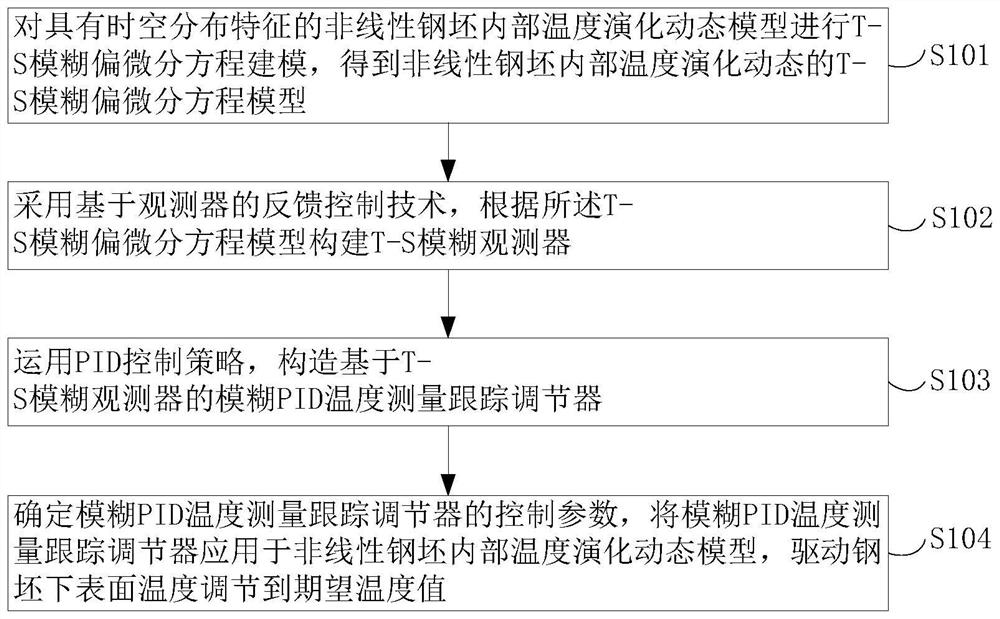

[0052] Such as Figure 3-Figure 4 As shown, the embodiment of the present invention provides a method for reheating fuzzy PID temperature adjustment method for billets produced by hot strip rolling, including:

[0053] S101, performing T-S fuzzy partial differential equation modeling on the nonlinear steel slab internal temperature evolution dynamic model with time-space distribution characteristics, and obtaining the T-S fuzzy partial differential equation model of the nonlinear steel slab internal temperature evolution dynamics; specifically, the following steps may be included:

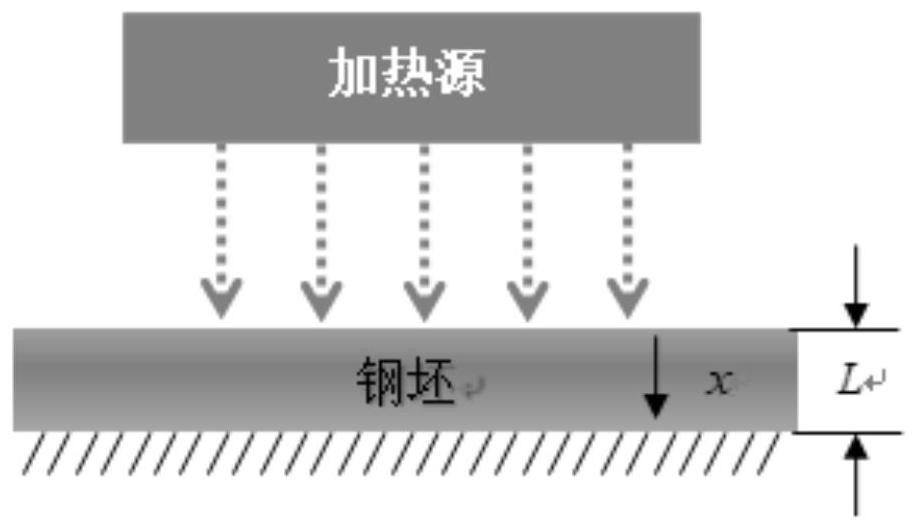

[0054] A1, simplify the dynamic model of the internal temperature evolution of the nonlinear billet with the characteristics of time and space distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com