Double-sided display panel and manufacturing method thereof

A double-sided display and panel technology, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as inability to meet double-sided display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

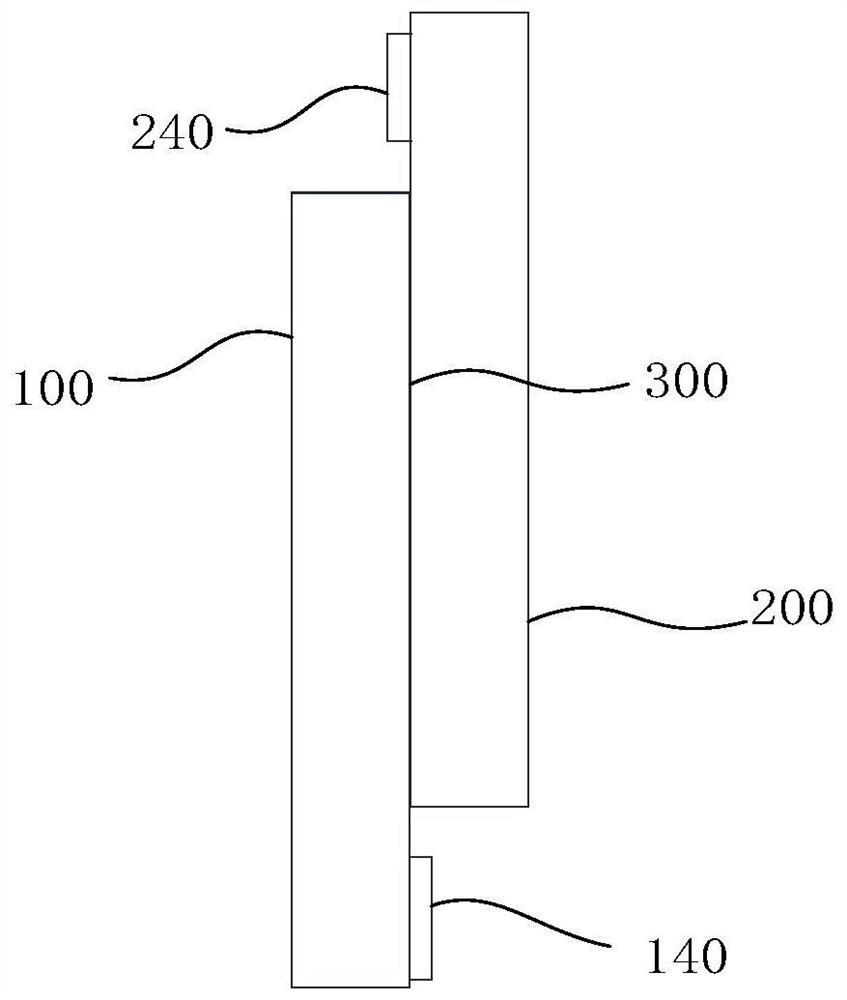

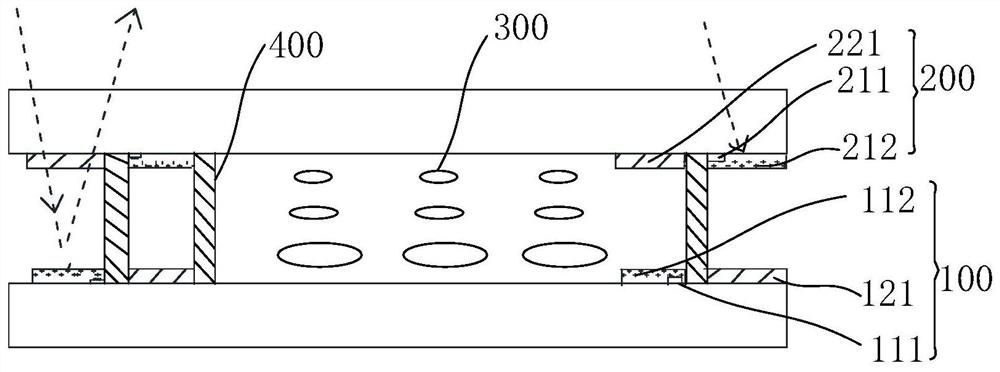

[0038] figure 1 is a schematic diagram of a double-sided display panel provided in the first embodiment of the present application, as shown in figure 1 As shown, a double-sided display panel 10 includes a first substrate 100, a second substrate 200 and a liquid crystal layer 300, the first substrate 100 and the second substrate 200 are oppositely arranged, and the first substrate 100 and the A liquid crystal layer 300 is arranged between the second substrates 200, the first substrate 100 includes a first reflective region 110 and a first transparent region 120, and the first reflective region 110 and the first transparent region 120 are arranged on the first The side of the substrate 100 close to the second substrate 200, the second substrate 200 includes a second reflective region 210 and a first transparent region 120, the second reflective region 210 and the second transparent region 220 are arranged on the first The second substrate 200 is close to the side of the first ...

no. 2 example

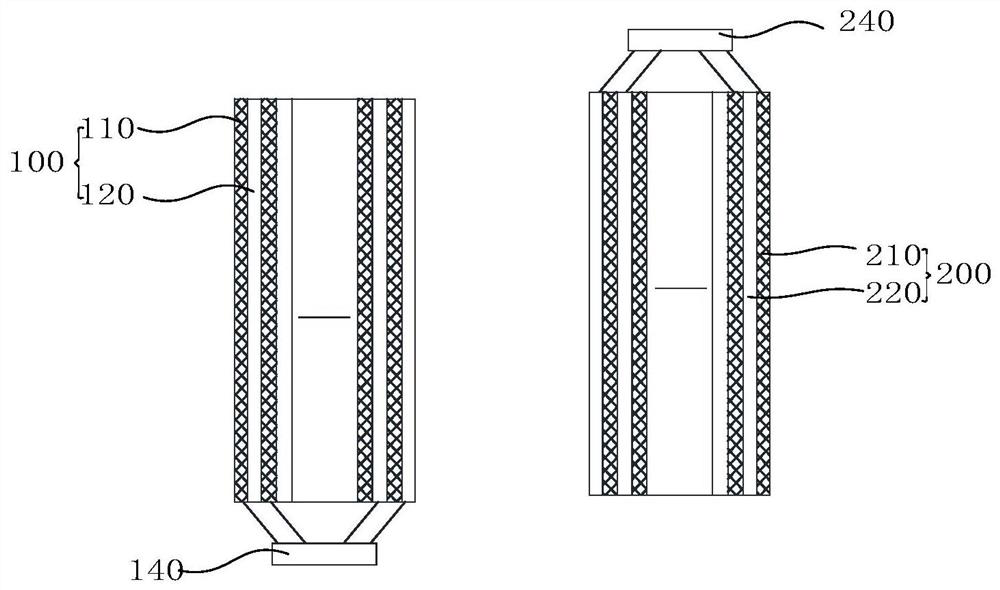

[0053] Figure 5 is a schematic diagram of a first substrate and a second substrate provided in the second embodiment of the present application, as shown in Figure 5 As shown, the difference between this embodiment and the first embodiment is that the first reflective regions 110 are arranged in rows along the data line direction to obtain the first reflective region rows, and the first transparent regions 120 are arranged in rows along the data line direction. arranging to obtain the first transparent region row, the first reflective region row and the first transparent region row are arranged at intervals; the second reflective region 210 is arranged in row along the data line direction to obtain the second reflective region row, The second transparent regions 220 are arranged in rows along the data line direction to obtain rows of second transparent regions, the rows of second reflective regions and the rows of second transparent regions are arranged at intervals between ...

no. 3 example

[0056] Figure 6 It is a schematic diagram of a first substrate and a second substrate provided in the third embodiment of the present application, as shown in Figure 6 As shown, the difference between this embodiment and the first and second embodiments is that the first reflective region 110 and the first transparent region 120 are arranged at regular intervals along the direction of the data line and the direction of the scan line; The two reflective regions 210 and the second transparent regions 220 are evenly arranged at intervals along the direction of the data line and the direction of the scan line. That is, in the horizontal direction, the first reflective regions 110 and the first transparent regions 120 in the first row are arranged evenly and evenly, and at the same time, the second reflective regions 210 and the second transparent regions 220 are arranged evenly and oddly; The regions 110 and the first transparent regions 120 are evenly arranged, while the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com