TYPE C connector and manufacturing method thereof

A connector and insulating body technology, which is applied in the field of TYPEC connectors and its production, can solve the problems of unsatisfactory bonding tightness, poor waterproof performance, and complicated process of the metal inner casing, so as to improve the bonding stability and assembly Good reliability, solve the effect of complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

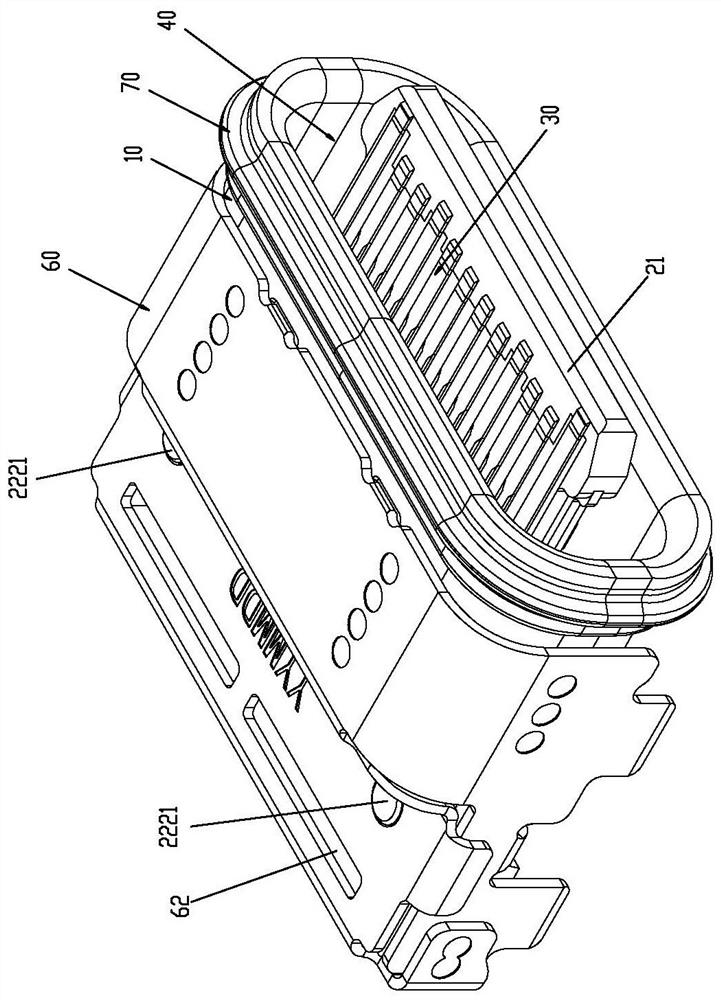

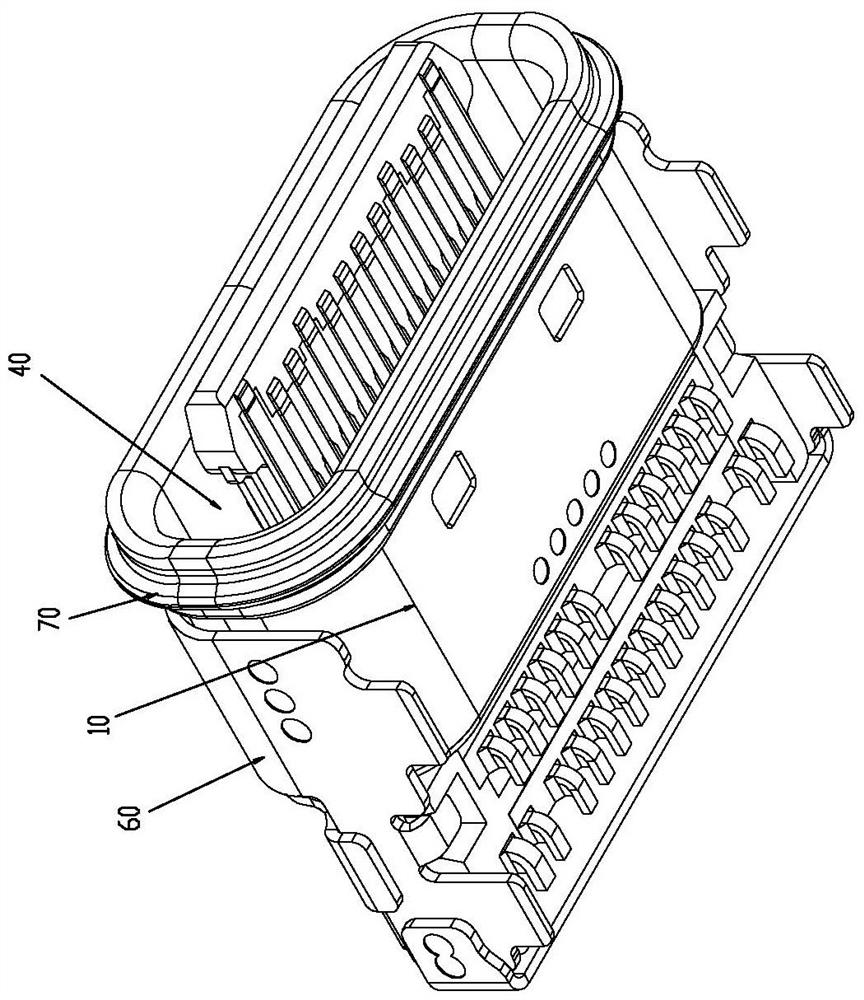

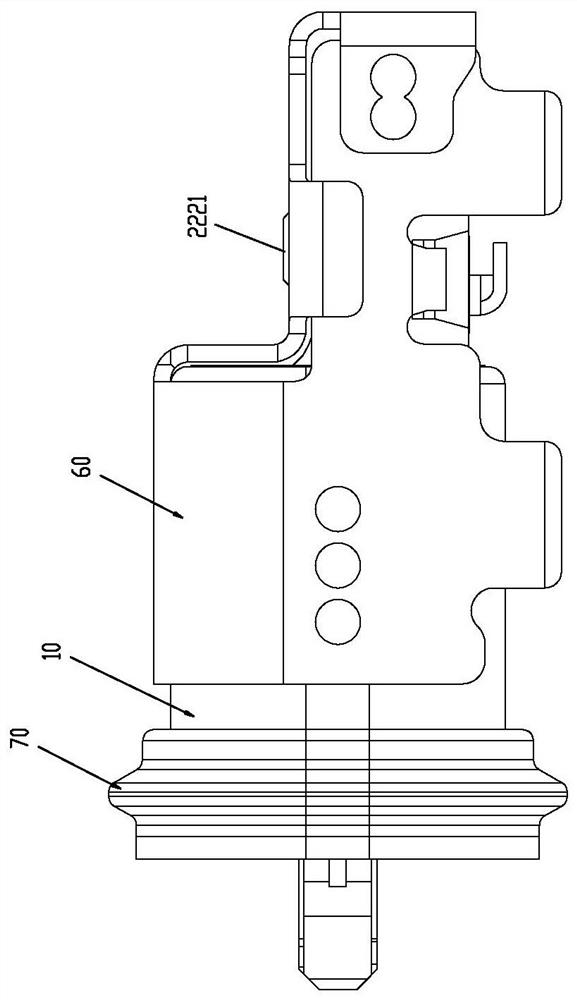

[0059] Please refer to Figure 1 to Figure 13 As shown, it shows the specific structure of the embodiment of the present invention.

[0060] A TYPE C connector, including a main metal shell 10, an insulating body 20 and a terminal group 30; the insulating body 20 has a tongue part 21 and a fixing seat 22 arranged in sequence from front to back; the terminal group 30 is arranged on On the insulating body 20, the terminal group 30 includes an upper row of terminals and a lower row of terminals respectively arranged on the upper and lower surfaces of the tongue part 21; the main metal shell 10 surrounds the outer periphery of the tongue part 21 to form a docking cavity 40. The insulating body 20 is inlaid with a metal fixing part 50 by injection molding, and the rear end of the metal fixing part 50 has an upper bending piece 51 extending upward and a lower bending piece 52 extending downward. The upper bending piece 51 and the lower bending piece 52 are respectively exposed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com