Overturning-free beam shelving bracket of movable arm tower crane and mounting method

A technology of shelving corbels and installation method, applied in cranes and other directions, to achieve the effects of reducing construction difficulty, saving resources and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

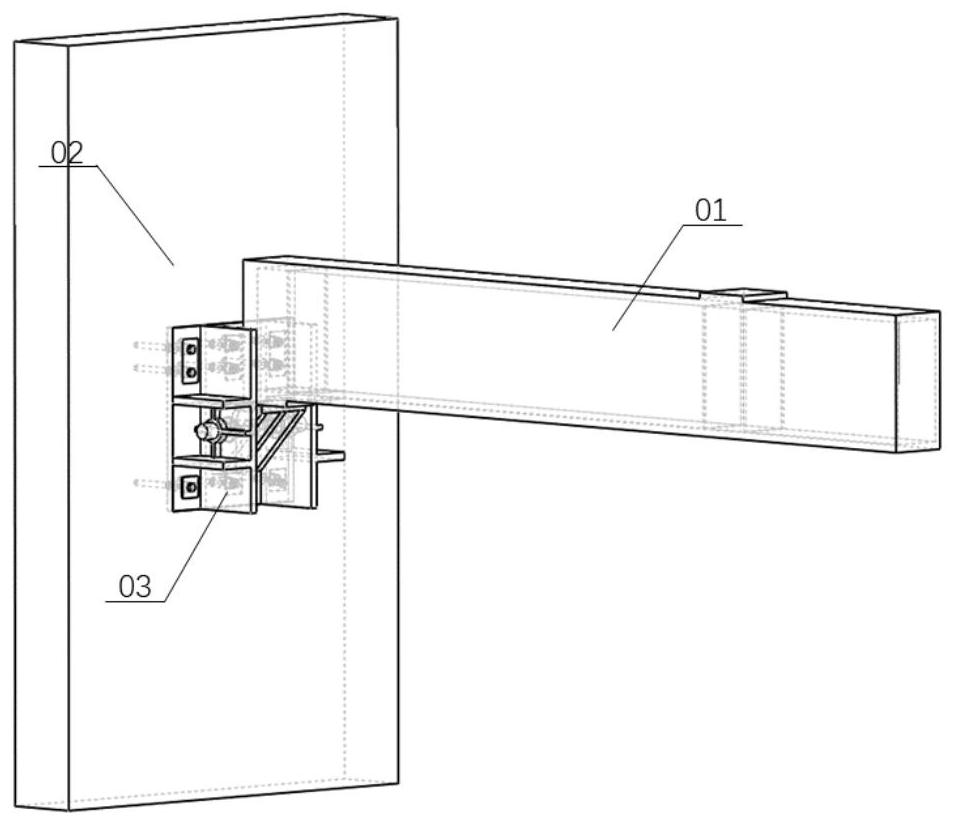

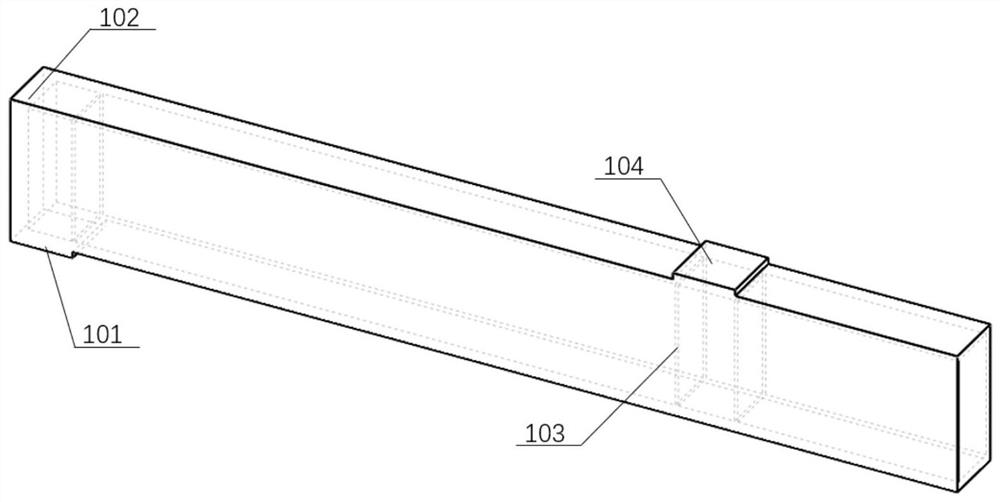

[0033] Combine below Figure 1 to Figure 12 , detailing the structural composition of the boom tower crane of the present invention without overturning beam resting corbels.

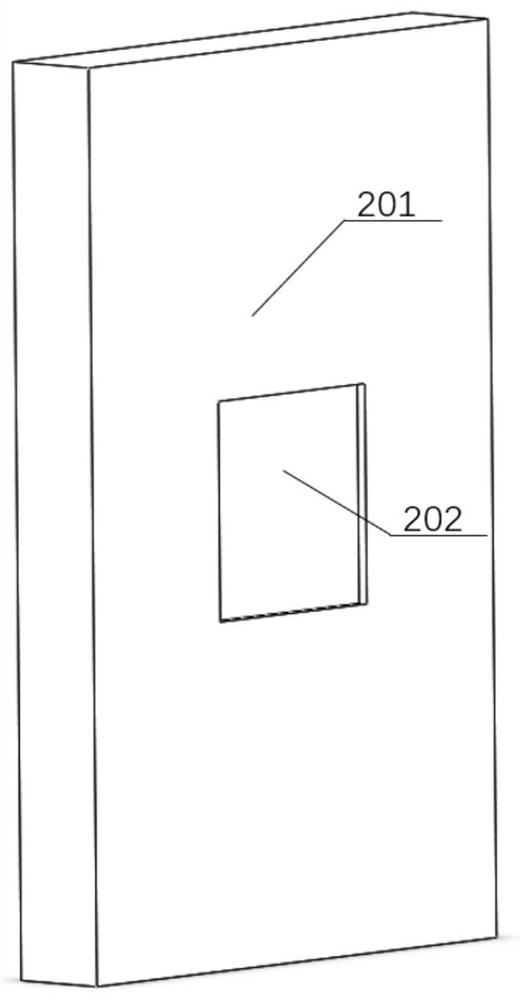

[0034] Please refer to Figure 1 to Figure 12 , a movable arm tower crane without overturning beams for shelving corbels, including a backboard 305 and a shelving steel tongue 310, the inner side of the backboard 305 is embedded in the pre-embedded area 202 of the concrete wall 02, the outer side of the backboard 305 is flush with the wall 201, and the backboard 305 is flush with the wall surface 201. Horizontal stiffeners 307 and vertical stiffeners 306 are fixed on the outer side of the plate 305, and the backplane 305 and the anchoring steel bar 301 are connected by a tapered sleeve 302. And fixed by the steel gasket 303 and fastening bolt 304 on the outside of the hole, one end of the smaller section of the tapered sleeve 302 is located on the inner side of the back plate 305, the anchoring steel ba...

Embodiment 2

[0046] Please continue to refer Figure 1 to Figure 12 , the present embodiment also provides a method for using a boom tower crane to leave a corbel without turning over a beam, and the method includes the following steps:

[0047] Step (1), when the tower crane climbs, the hoisting beam 01 lifts the first hoisting beam 01 by means of a winch placed on the top of the standard section;

[0048] Step (2), when the lifting beam 01 is lifted to the shelving corbel 03, and contacts with the shelving steel tongue 310 of the shelving corbel 03;

[0049] Step (3), continue to lift the lifting beam 01, at this time, the lifting beam 01 pushes the shelving steel tongue 310 to rotate, leaving space for the lifting beam 01 to continue to lift;

[0050] Step (4), after the lifting beam 01 continues to lift over the shelving steel tongue 310, the shelving steel tongue 310 is reset under the action of gravity;

[0051] Step (5), playback the lifting beam 01, put the lifting beam 01 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com