Flexible framework of bogie of railway wagon and the railway wagon

A technology for railway freight cars and bogies, which is applied in the directions of bogies, railway car body components, devices for lateral relative movement between the underframe and the bogies, etc., to achieve the effect of strong line capability and strong resistance to diamond deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

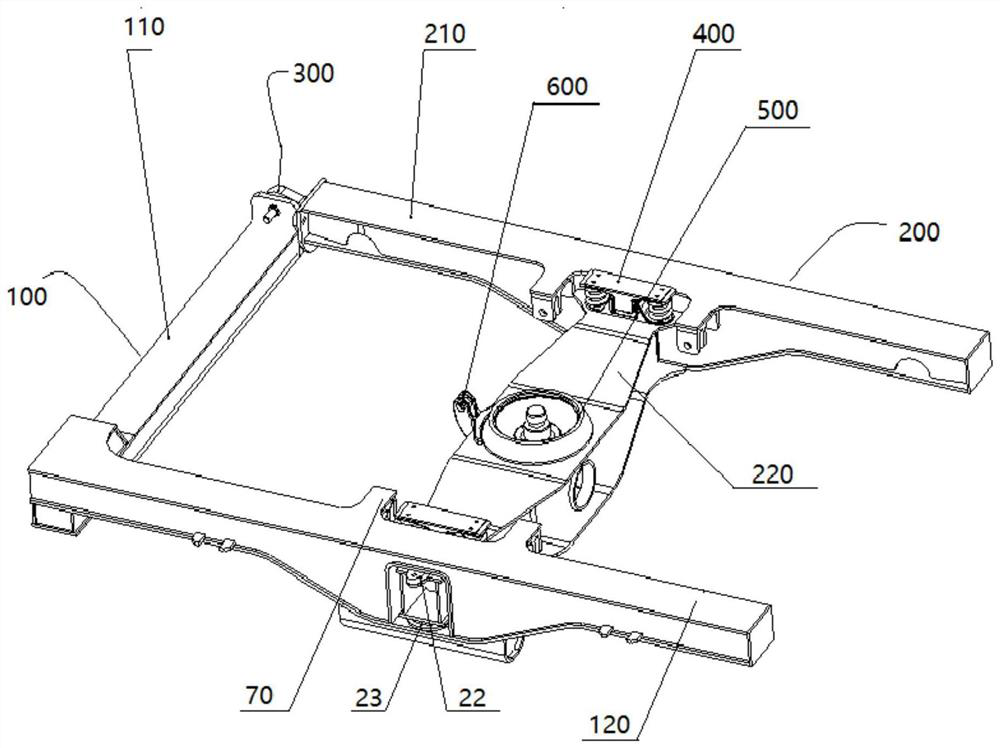

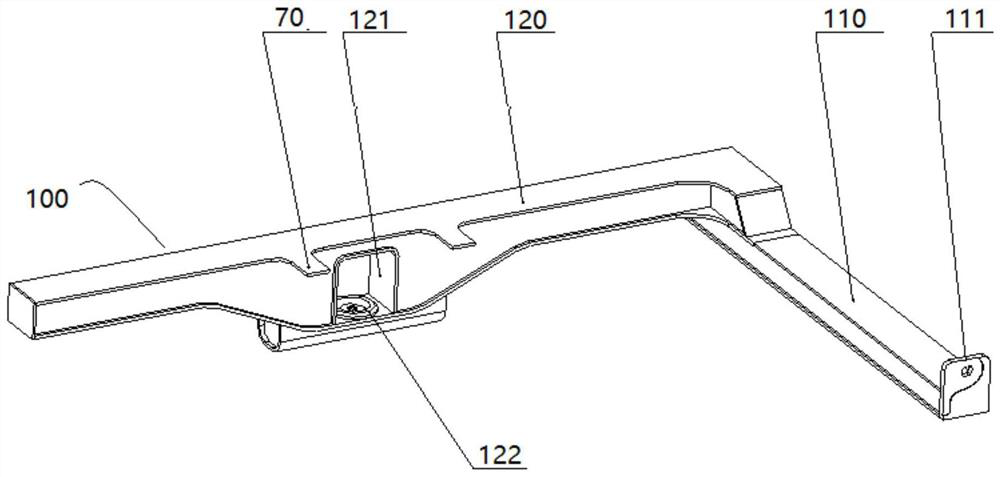

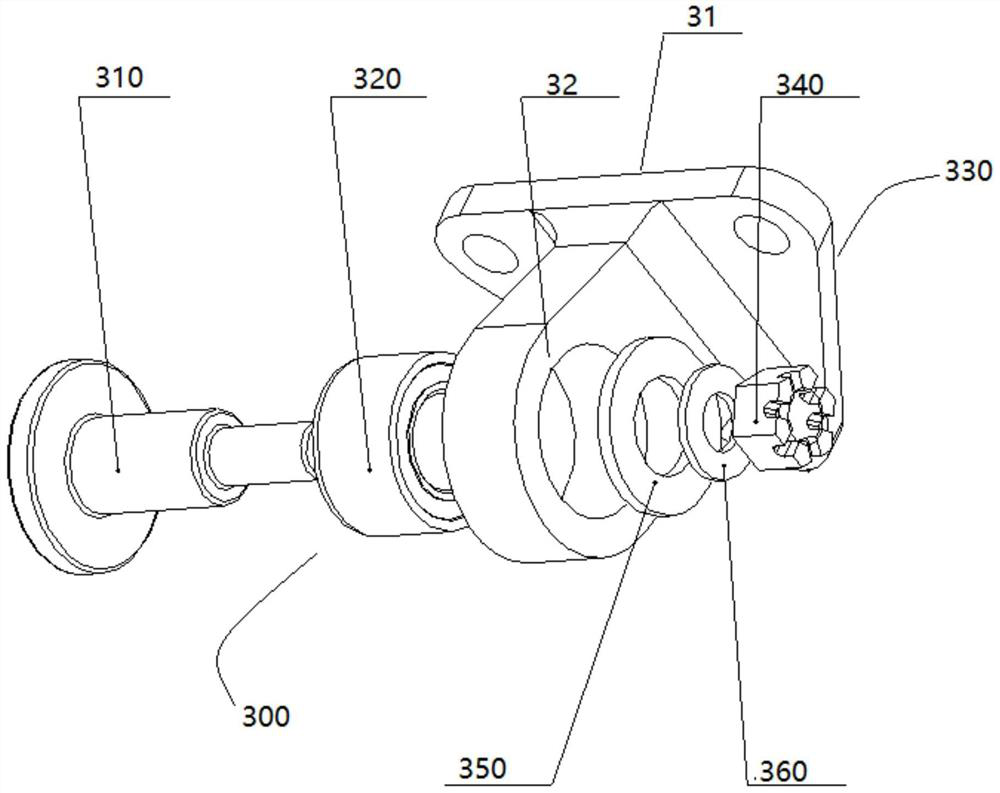

[0036] figure 1 It is a structural schematic diagram of a flexible framework of a railway freight car bogie according to the present invention. figure 2 It is a schematic diagram of an L-shaped beam of a flexible frame of a railway freight car bogie according to the present invention. Figure 5 It is a schematic diagram of a T-beam of a flexible frame of a railway freight car bogie according to the present invention.

[0037] The flexible frame of the railway freight car bogie in this embodiment includes an L-shaped beam 100 , a T-shaped beam 200 , a connecting member 300 , an elastic side bearing 400 , a lower center plate 500 and a fulcrum seat 600 .

[0038] Such as figure 1 and figure 2 As shown, L-beam 100 includes end beams 110 and side beams A 120 . The side beam A 120 is fixedly connected to the end beam 110, and the angle between them is 90 degrees. An L-shaped beam connecting plate 111 is provided at the end of the end beam 110 away from the side beam A 120 . ...

Embodiment 2

[0048] This embodiment provides a railway freight car, which includes the flexible frame of the railway freight car bogie in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com