Water meter shell forming mold facilitating mold opening and part taking and forming method of water meter shell forming mold

A shell forming and mold technology is applied to the water meter shell forming mold and its forming field, which can solve the problems of reducing the forming quality of the water meter shell, inconvenient to open the mold for the water meter shell, and lack of buffer structure buffer protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

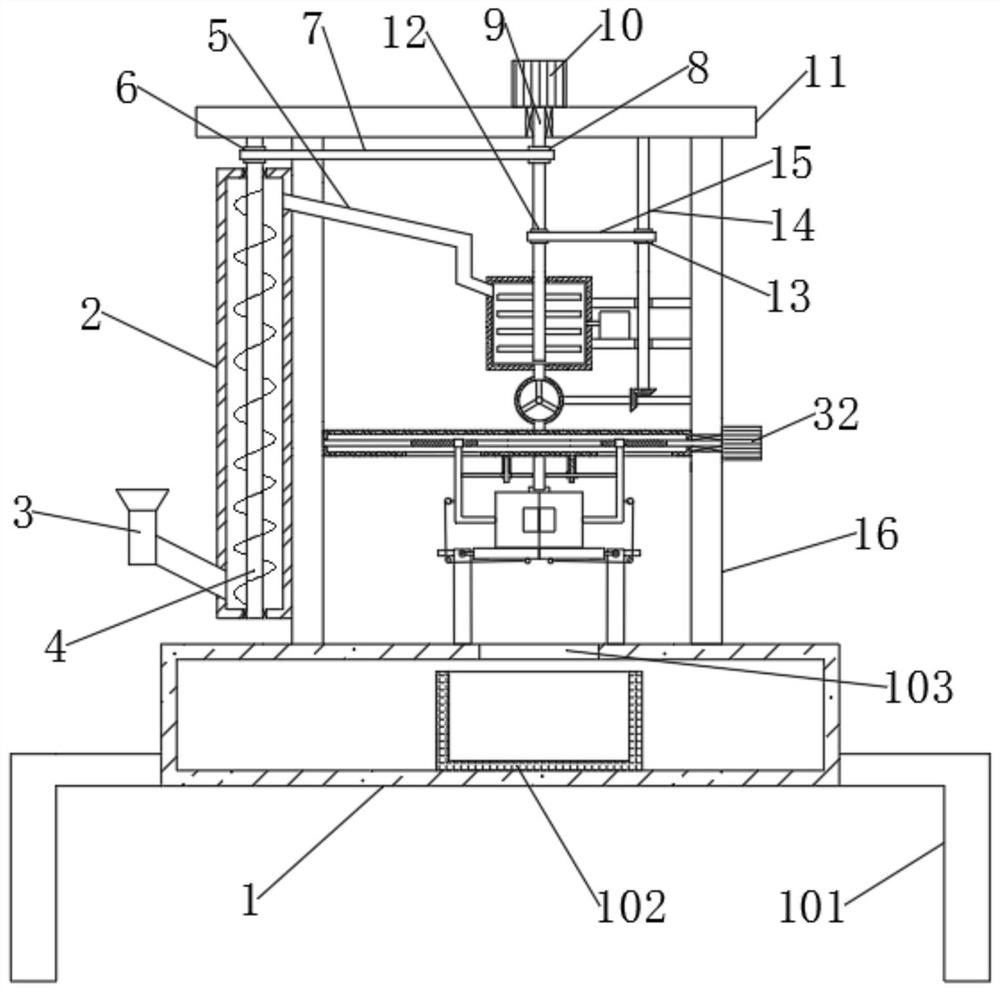

[0041] A mold for forming a water meter shell that is convenient for mold opening and parts extraction, comprising a workbench 1, support legs 101 are installed at the left and right ends of the workbench 1, the front end of the workbench 1 is set as an opening, the upper end is symmetrically installed with brackets 16, and the middle of the upper end is set There is a feeding port 103;

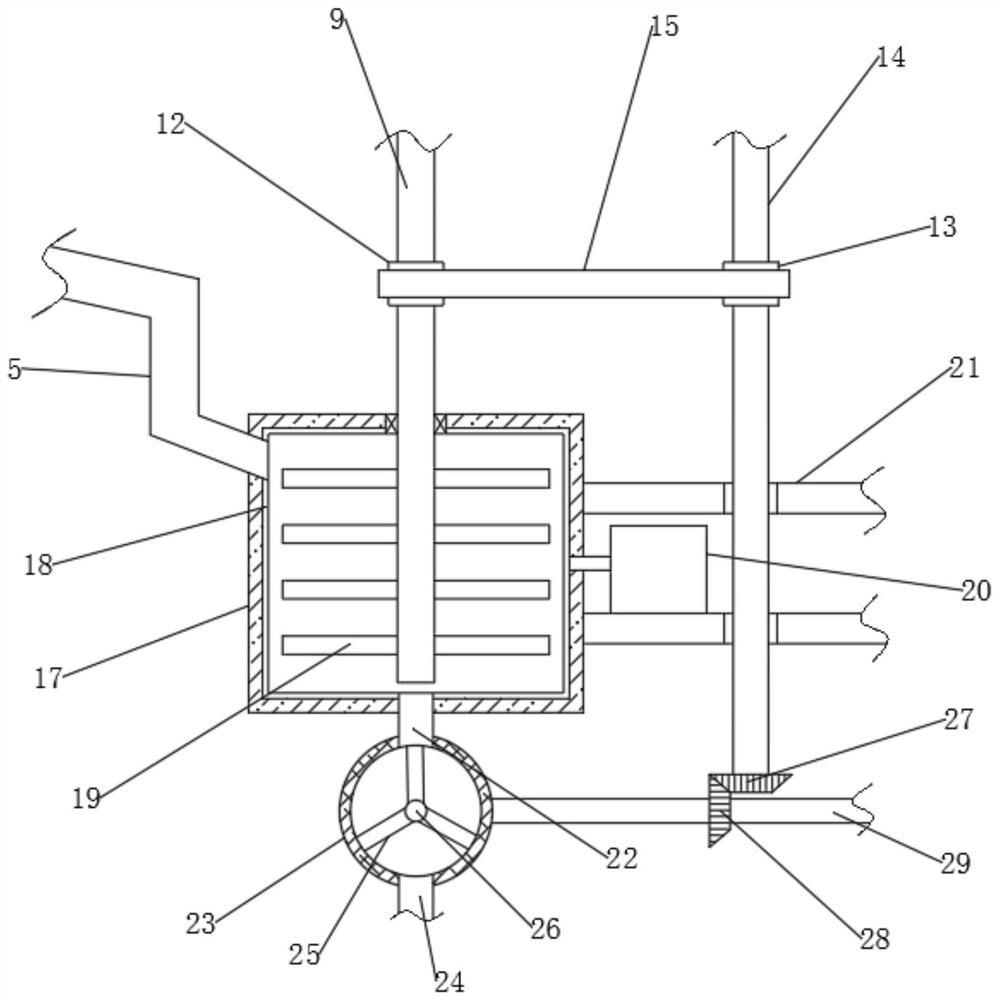

[0042] The upper ends of the two supports 16 are all connected with the bottom end of the top plate 11, the left end of the left support 16 is equipped with a feeding mechanism, and the left end of the right support 16 is connected with the right end of the mixing box 17 through a vertically symmetrical fixed plate 21, between the two supports 16 A box body 33 is installed;

[0043] The top plate 11 upper end is equipped with a first motor 10, the first motor 10 is connected with a rotating shaft-9 downwards, the rotating shaft-9 passes through the top plate 11 downwards, and stretches into t...

Embodiment 2

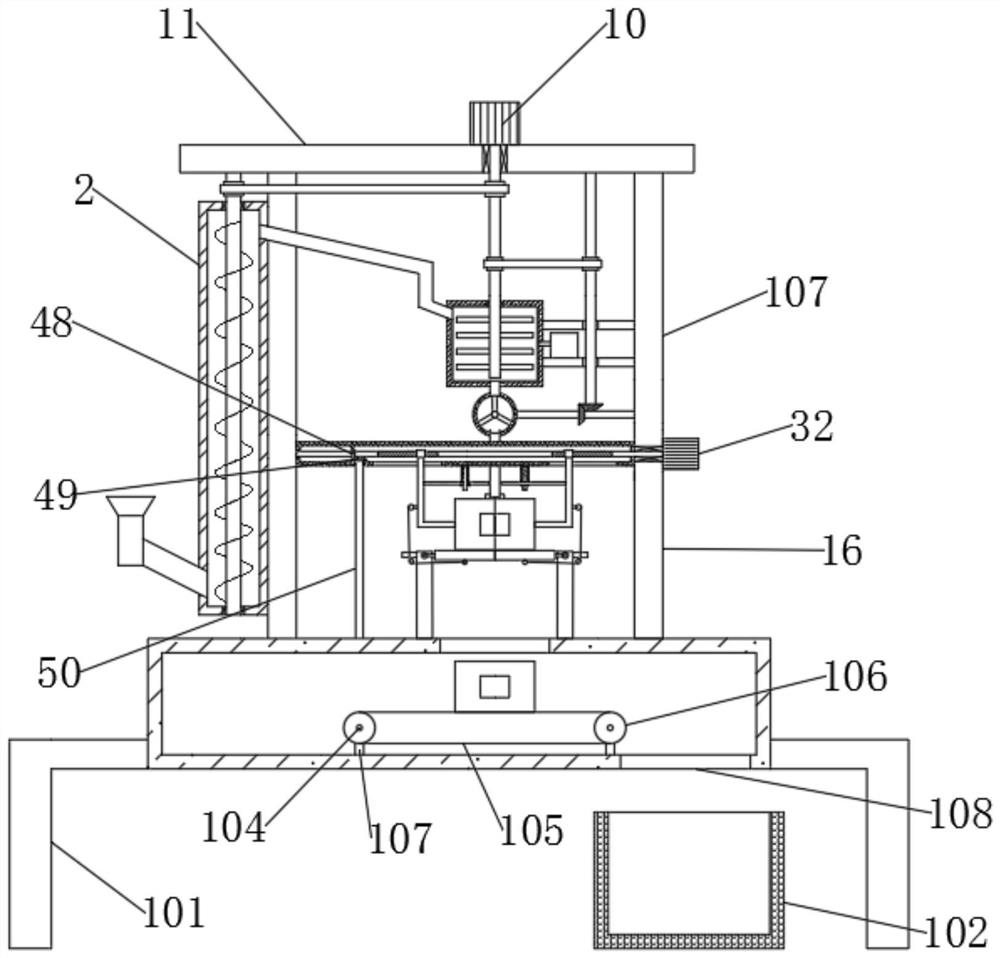

[0057] The difference from Example 1 is:

[0058]Inside the workbench 1, a conveying assembly is installed corresponding to the feeding port 103. The conveying assembly includes a No. 5 pulley 106. Two No. 5 pulleys 106 are connected together through a transmission belt 3 105. The two No. 5 pulleys 106 are installed on the shaft 6 104 respectively. Above, two rotating shafts 6 104 are rotatably connected on the mounting bracket 107, and the rear end of one of the rotating shafts 6 104 is equipped with five types of bevel gears 52, the fifth types of bevel gears 52 mesh with the six types of bevel gears 51, and the six types of bevel gears 51 Installed on the rotating shaft seven 50, the rotating shaft seven 50 protrudes upwards from the workbench 1 and extends into the box body 33, and is connected with seven types of bevel gears 49, the seven types of bevel gears 49 mesh with the eight types of bevel gears 48, and the eight types of bevel gears The bevel gear 48 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com