Relay housing comprehensive batch glue scraping equipment for PLC automatic control

A technology of automatic control and relay cover, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of slow processing speed, influence, inconvenient operation, etc., and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

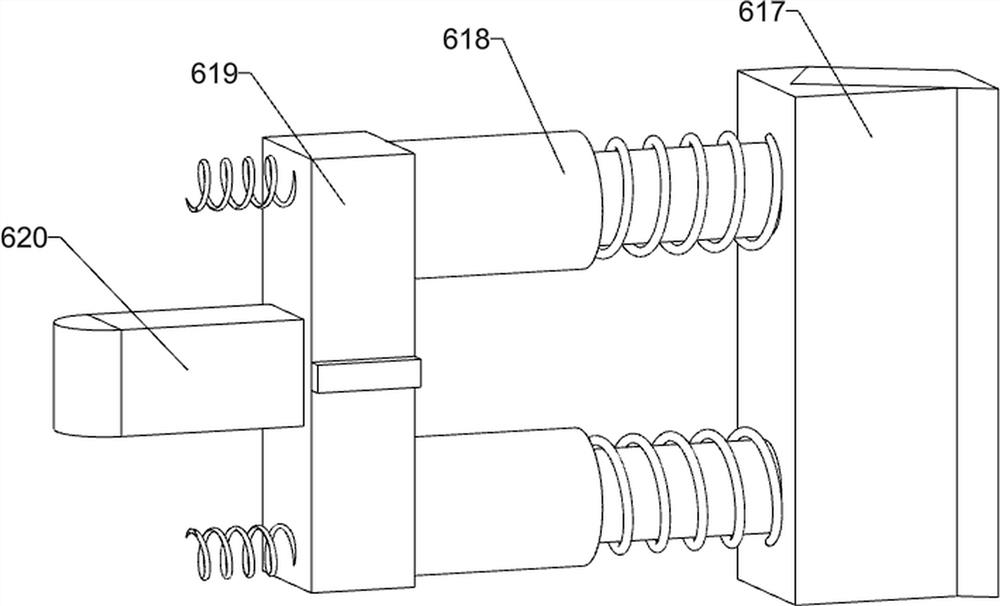

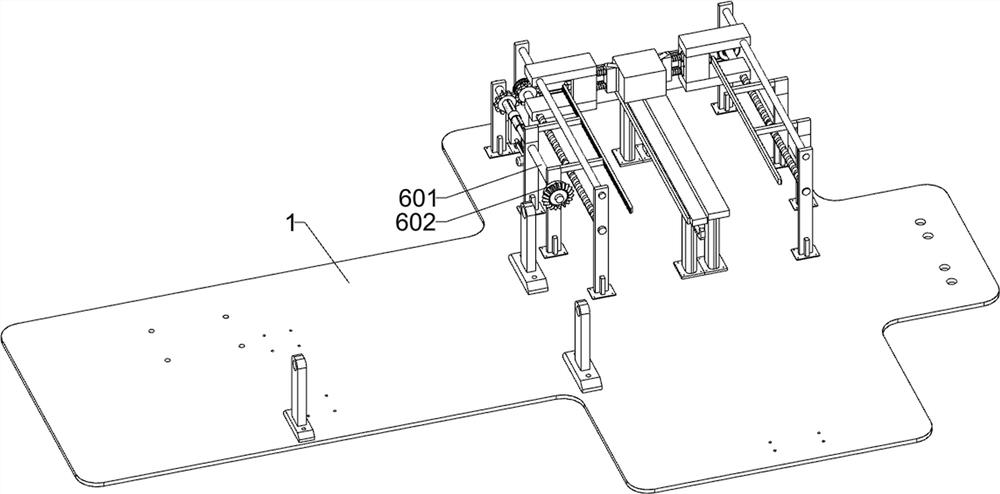

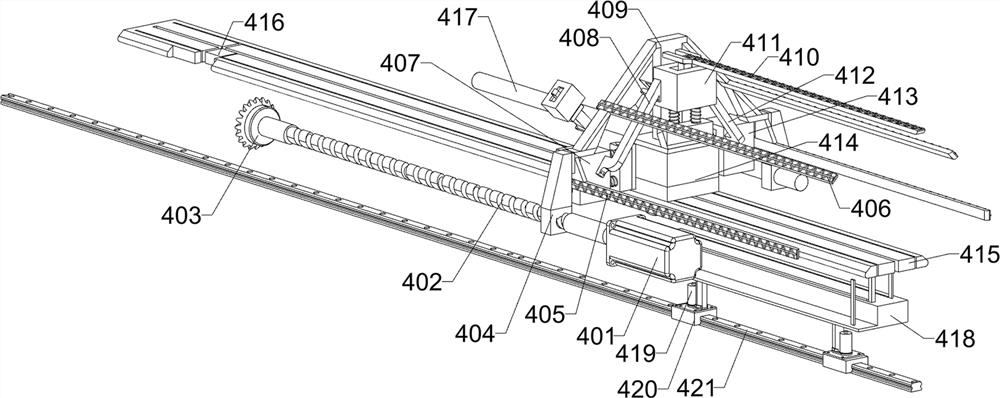

[0036] A comprehensive batch scraping equipment for PLC automation control relay cover, refer to Figure 1-2 As shown, it includes an underframe 1, a first support frame 2, a first fixed frame 3, a first connecting frame 4, a second fixed frame 5, a second support frame 6, a third support frame 7, and a first fixed plate 8. , double-sided squeegee assembly and bonding surface squeegee assembly; the bottom frame 1 is fixedly connected with the first support frame 2, the first fixed frame 3, the first connecting frame 4 and the second fixed frame 5; the first connecting frame 4 It is affixed to the first fixed plate 8; two groups of second support frames 6 and third support frames 7 are all affixed to the bottom frame 1; a double-sided squeegee assembly is arranged above the bottom frame 1; the double-sided squeegee assembly is connected to the The bonding surface scraping assembly is connected; the double-sided scraping assembly is connected with the first supporting frame 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com