Receiving type dust remover

A dust collector and storage box technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inconvenient cleaning of dust, inconvenient maintenance and repair of dust collectors, etc., and achieve easy promotion, use, installation and disassembly The method is simple and convenient for maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

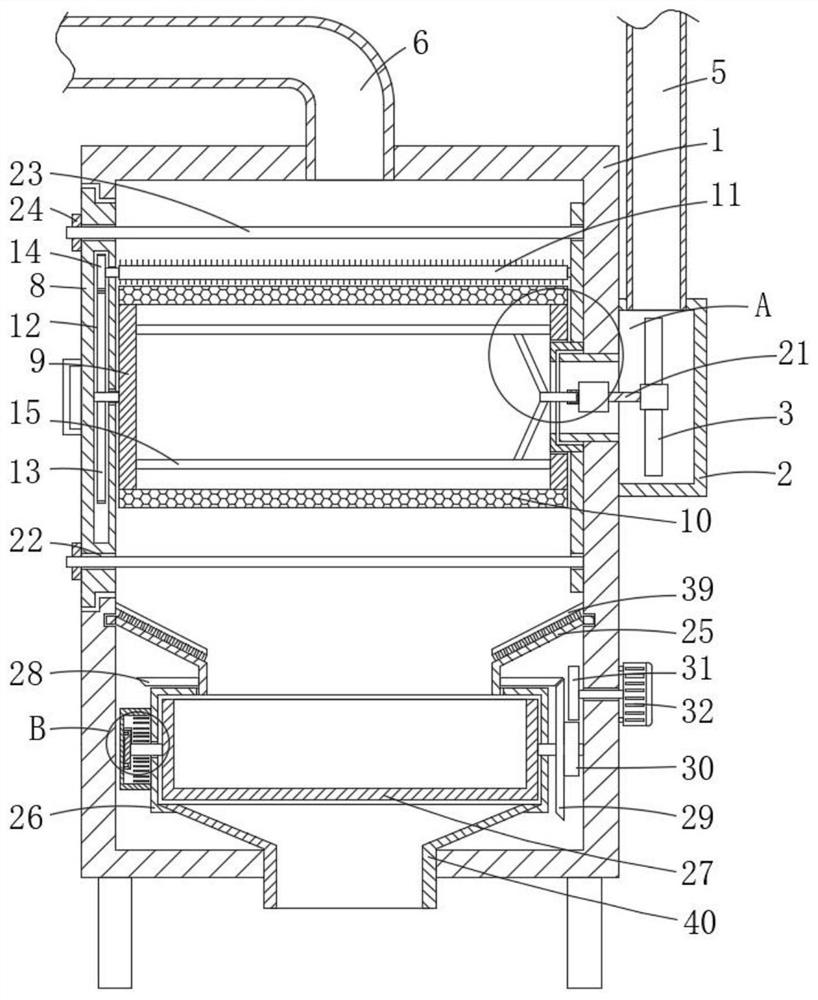

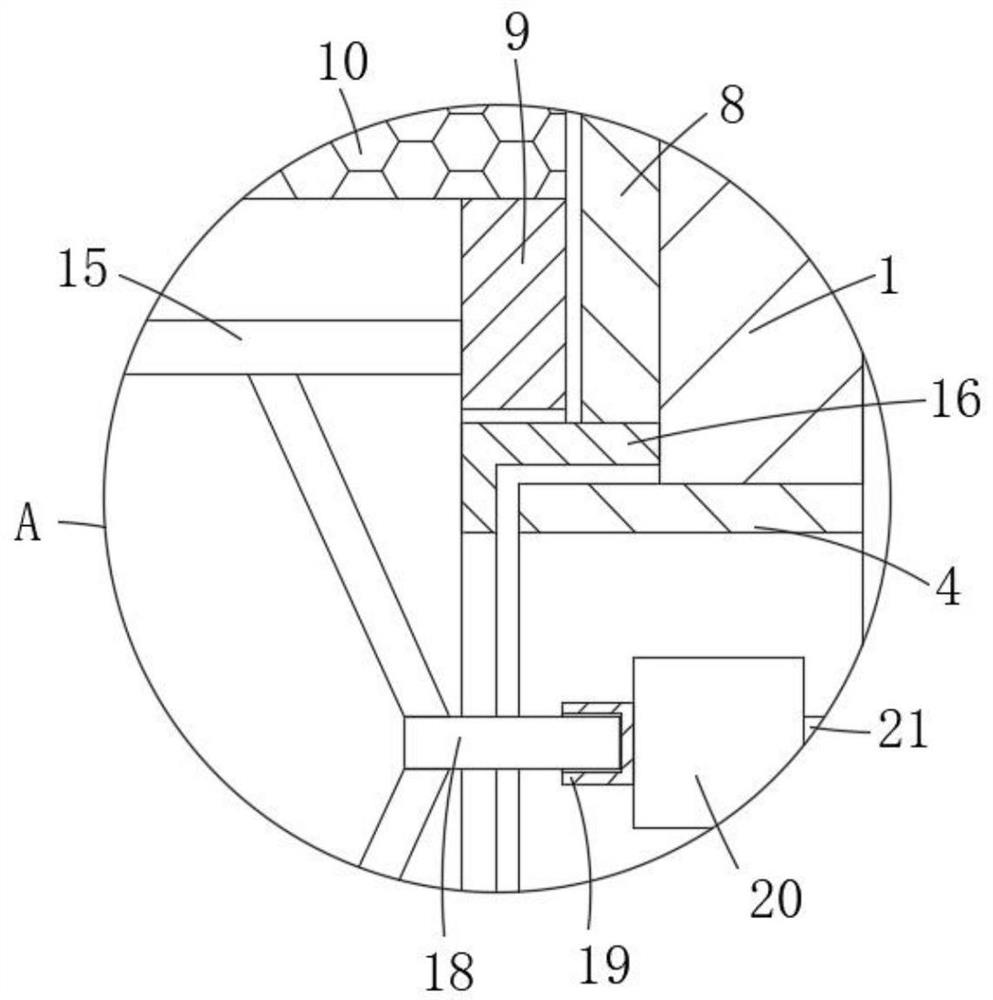

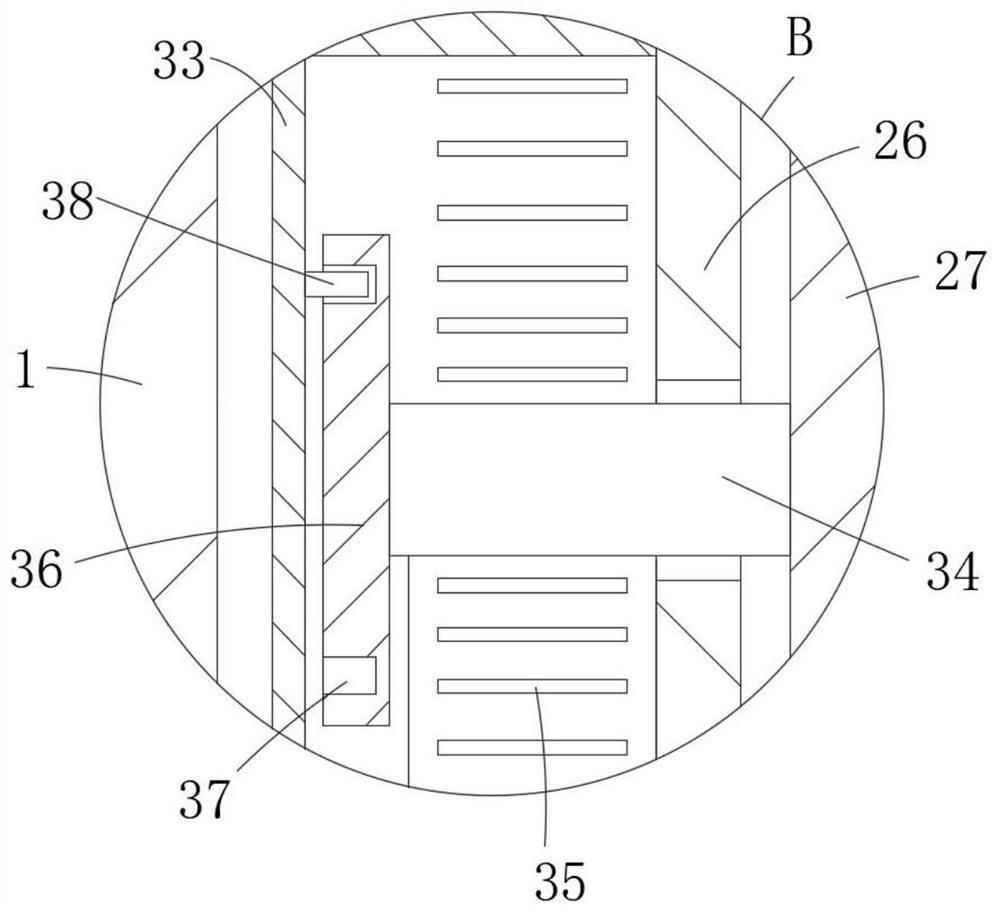

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0033] refer to Figure 1-7 , a collection type dust collector, including a housing 1, the top of the housing 1 is fixed with an air inlet pipe 6, the outer side of the housing 1 is fixed with an installation box 2, and an exhaust fan 3 is installed on the installation box 2, The top of the installation box 2 is fixed with a discharge pipe 5, and the exhaust fan 3 rotates to extract the air inside the casing 1 to the outside of the casing 1, forming a negative pressure inside the casing 1, and passing through the air inlet pipe 6 to facilitate the removal of the air to be filtered. The air is delivered to the inside of the housing 1 .

[0034] The inner side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com