Ophthalmological implant and method for the production of same

An implant, ophthalmology technology, applied in eye implants, medical science, intraocular lens, etc., can solve problems such as confusion residual risk, wrong identification of intraocular lens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

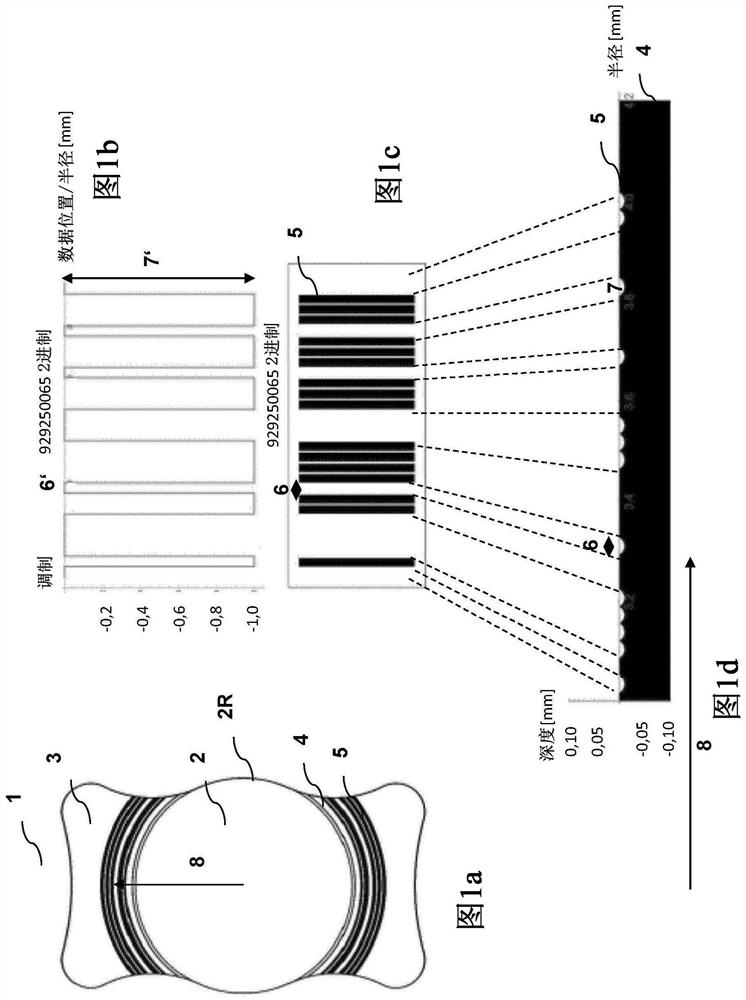

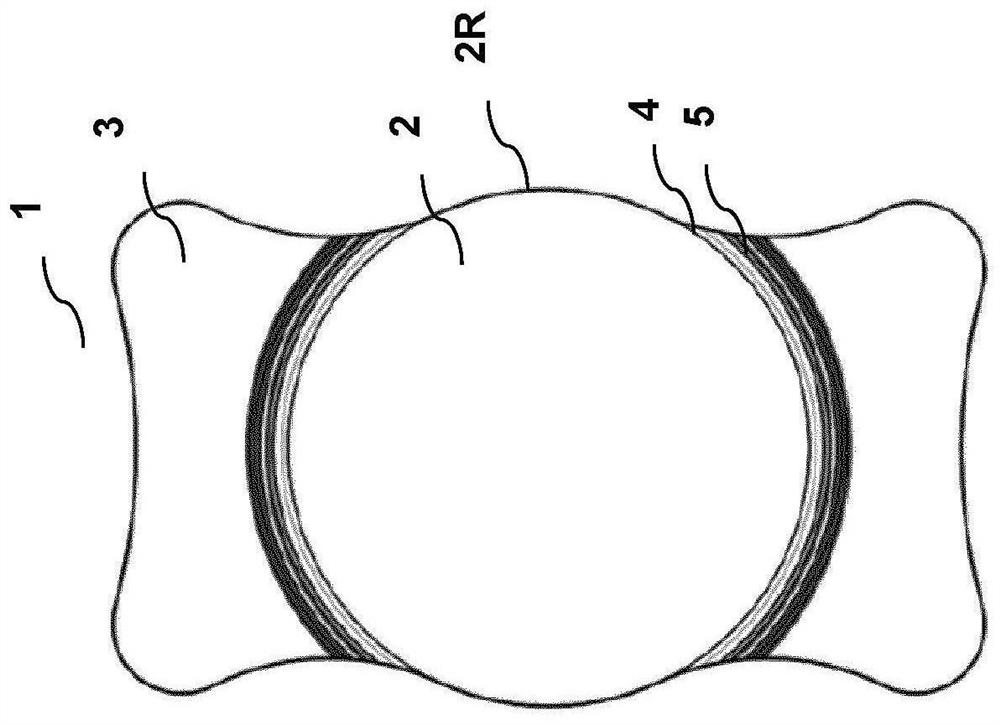

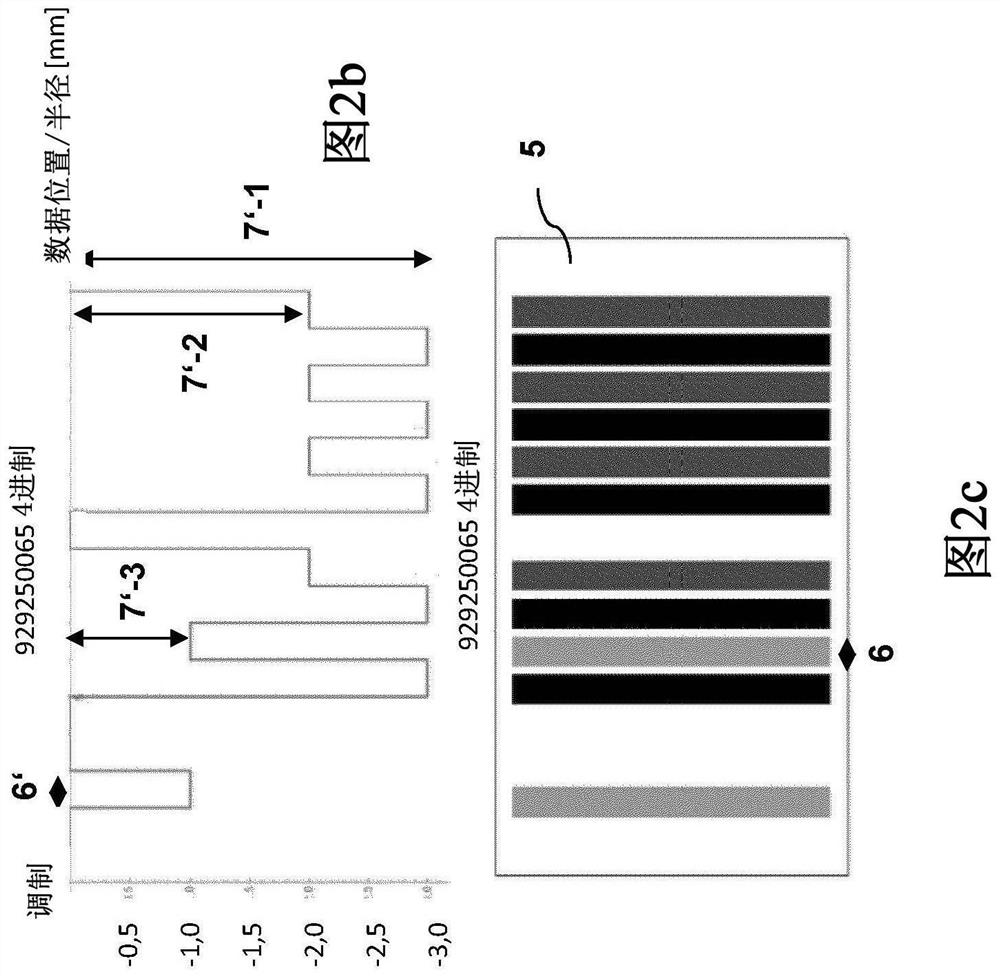

[0067] Figure 1a is a first embodiment of an ophthalmic implant 1 with a structured code 5 according to the invention. The ophthalmic implant 1 is an intraocular lens comprising a central optical lens 2 representing the optical imaging element of the ophthalmic implant 1 and a haptic 3 having a haptic root 4 along the annular edge 2R of the central optical lens 2 The subregions of are connected to the central optical lens 2 and here partially surround the central optical lens from both sides. A structured code 5 of identification data of the ophthalmic implant 1 is arranged at the haptic root 4 of the intraocular lens and at the region of the haptic device 3 close to the haptic root 4 . Here, in this case, the structured code 5 of the type and refractive power of the intraocular lens. In this case, the structured code 5 is used in the form of a barcode system, ie arranged rotationally symmetrically around the central optical lens 2 on the haptic root 4 and on the haptic devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com