Optical cable

A technology of optical cable and buffer layer, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of limited compressive performance and increased specific gravity of optical cables, and achieve the effects of improving compressive performance, avoiding damage to optical fibers, and avoiding direct stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

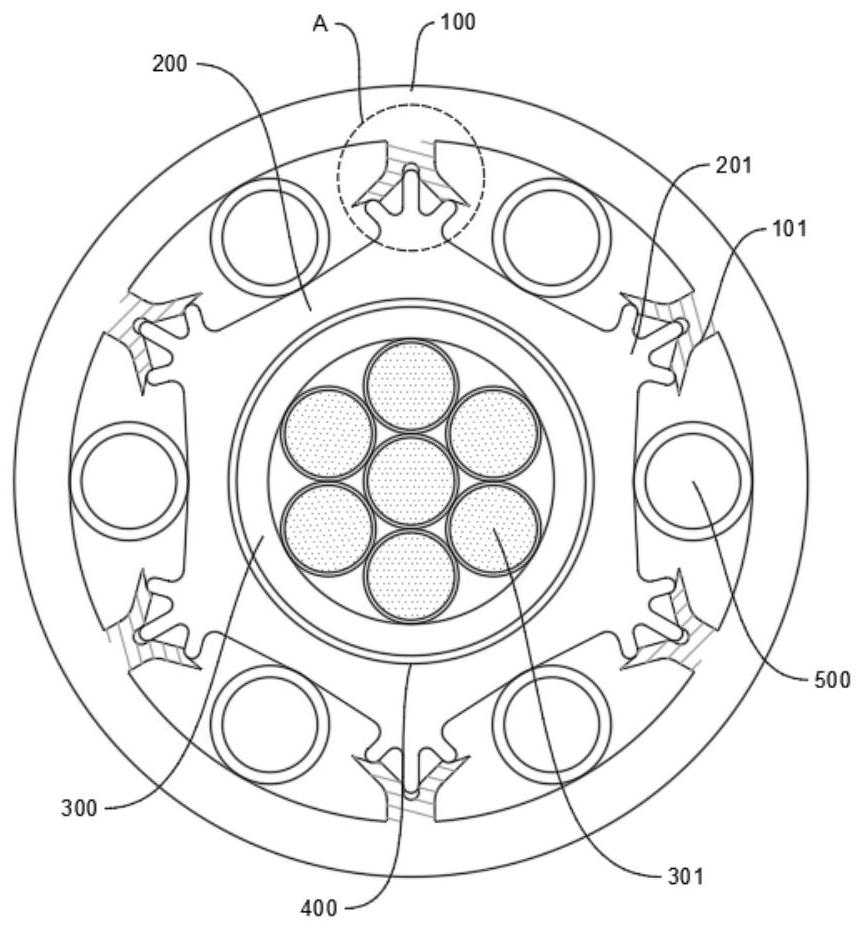

[0040] a kind of like figure 1 The pressure-resistant optical cable shown specifically includes:

[0041] A sheath layer 100, a structural buffer layer 200, a non-woven fabric wrapping layer 400, a bundle tube 300 and an optical fiber layer 301 are sequentially arranged from outside to inside;

[0042] The bundle tube 300 is coated on the outer surface of the optical fiber layer. The optical fiber layer is composed of several optical fiber lines. The optical fiber lines are single-mode optical fibers or multi-mode optical fibers or optical fiber bundles. fixed;

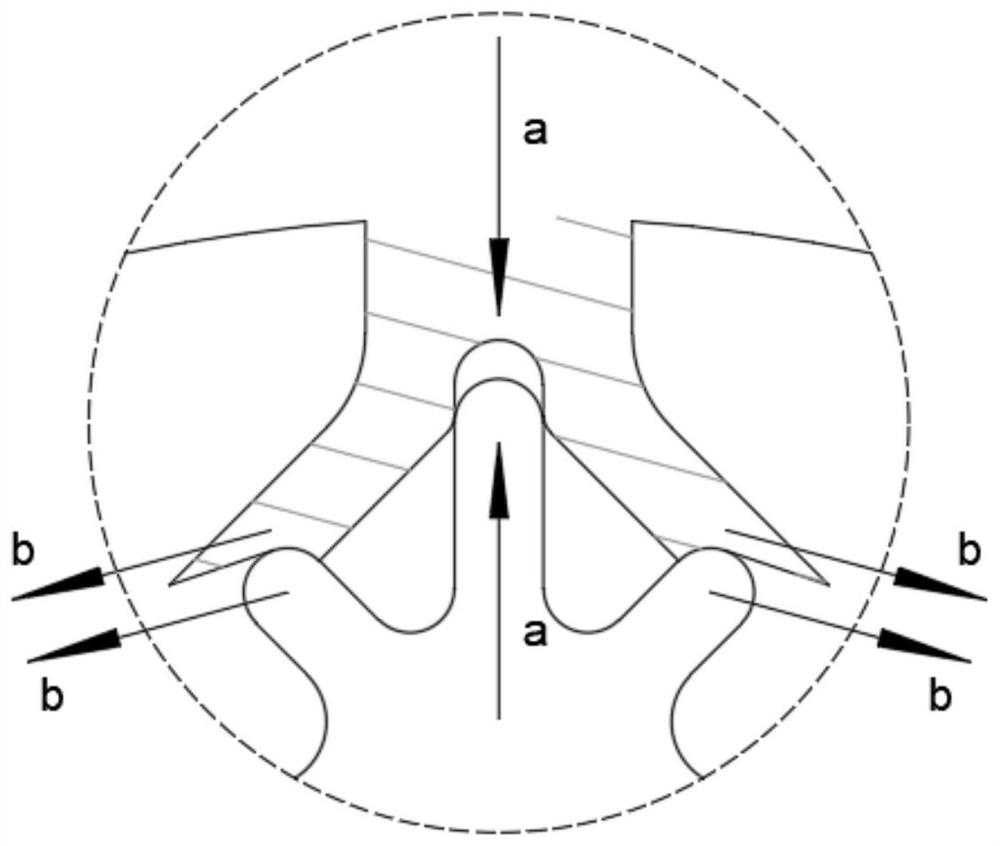

[0043] The radial cross-section of the optical cable of the main body of the structural buffer layer 200 is a regular polygon. For example, in this embodiment, the radial cross-section is a regular hexagon. The edge of the main body of the structural buffer layer 200, namely figure 1 At the corner of the radial cross-section of the main body of the hexagonal structure buffer layer 200, an outwardly protruding inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com