Energy-saving type production and processing auxiliary equipment for plastic particles with same size

A technology with the same size and plastic particles, applied in the direction of coating, etc., can solve the problems of waste of resources, different sizes of plastic particles, and affect the quality of plastic particles, and achieve the centralized processing of recycled resources, the same size of plastic particles, and ensure production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

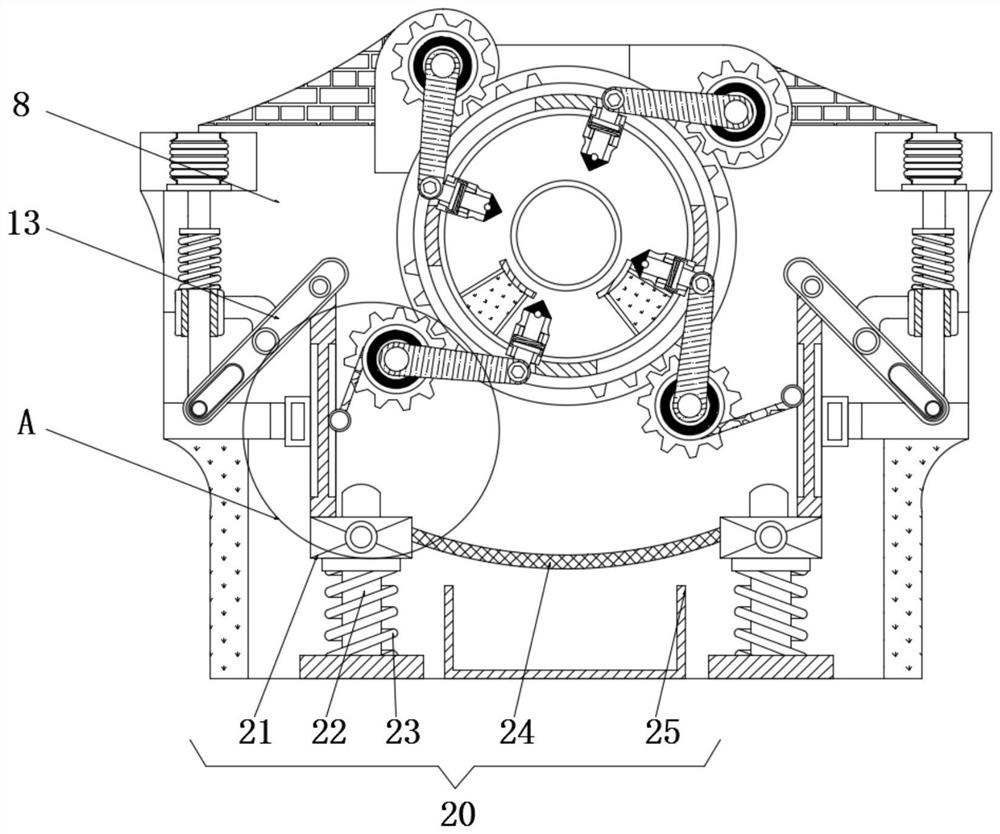

[0023] An energy-saving production and processing auxiliary equipment with the same size of plastic particles, including a protective component 12 and a screening component 20. The screening component 20 includes a rectangular slide plate 21, and a guide rod 22 is inserted inside the rectangular slide plate 21. The surface is located on the outside of the guide rod 22 and is fixedly connected with the limit spring 23. The right side of the rectangular slide plate 21 is fixedly connected with a screening filter 24, and between the two guide rods 22 is fixedly connected with a recovery box under the screening filter 24. 25.

[0024] It also includes a particle control assembly 1, the particle control assembly 1 includes a rotating gear 2, a coaxial connecting rod 3 is connected to the center of the front surface of the rotating gear 2, and a torsion spring 4 is fixedly connected to one end of the coaxial connecting rod 3 close to the rotating gear 2, The end of the coaxial conne...

specific Embodiment 2

[0027] An energy-saving production and processing auxiliary equipment with the same size of plastic particles, including a protective component 12 and a screening component 20. The screening component 20 includes a rectangular slide plate 21, and a guide rod 22 is inserted inside the rectangular slide plate 21. The surface is located on the outside of the guide rod 22 and is fixedly connected with the limit spring 23. The right side of the rectangular slide plate 21 is fixedly connected with a screening filter 24, and between the two guide rods 22 is fixedly connected with a recovery box under the screening filter 24. 25.

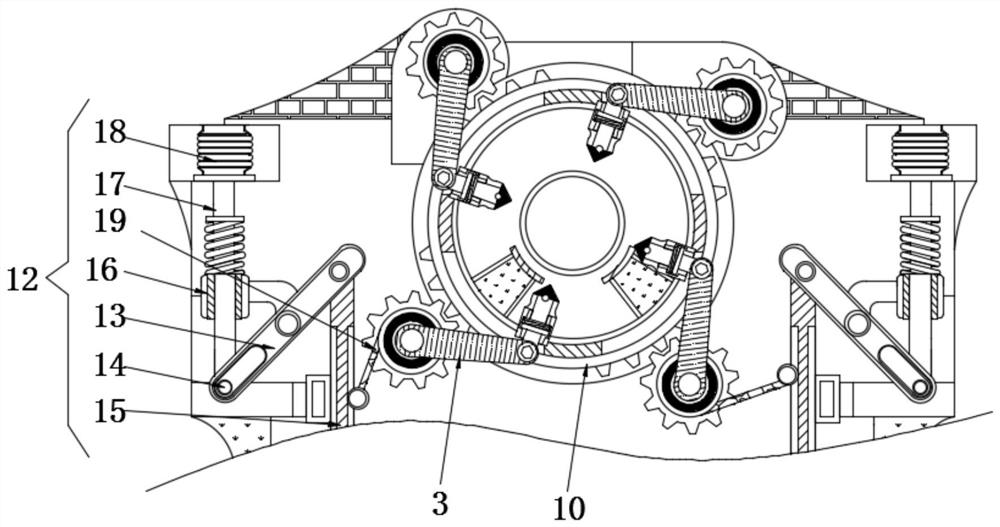

[0028] The protective assembly 12 includes a lever 13, the lower end of the lever 13 is slidingly connected with a positioning pin 14, the end of the lever 13 away from the positioning pin 14 is fixedly connected with a vertical pressing plate 15, the rear surface of the positioning pin 14 is fixedly connected with a push plate 17, and the push plate The ou...

specific Embodiment 3

[0031] An energy-saving production and processing auxiliary equipment with the same size of plastic particles, including a protective component 12 and a screening component 20. The screening component 20 includes a rectangular slide plate 21, and a guide rod 22 is inserted inside the rectangular slide plate 21. The surface is located on the outside of the guide rod 22 and is fixedly connected with the limit spring 23. The right side of the rectangular slide plate 21 is fixedly connected with a screening filter 24, and between the two guide rods 22 is fixedly connected with a recovery box under the screening filter 24. 25.

[0032] It also includes a particle control assembly 1, the particle control assembly 1 includes a rotating gear 2, a coaxial connecting rod 3 is connected to the center of the front surface of the rotating gear 2, and a torsion spring 4 is fixedly connected to one end of the coaxial connecting rod 3 close to the rotating gear 2, The end of the coaxial conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com