A suspension mechanism detection device based on automobile performance test

A suspension mechanism and detection device technology, which is applied in the direction of vehicle suspension/shock absorption mechanism testing, etc., can solve the problems of inconvenient simulation of vehicle status, difficulty in providing simulated bumping function, lack of pressure deviation force measurement function, etc., to achieve convenient manual The effect of handling test, high adaptability and high locking and fixing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

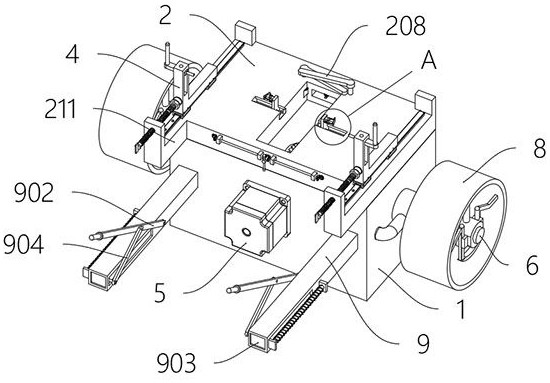

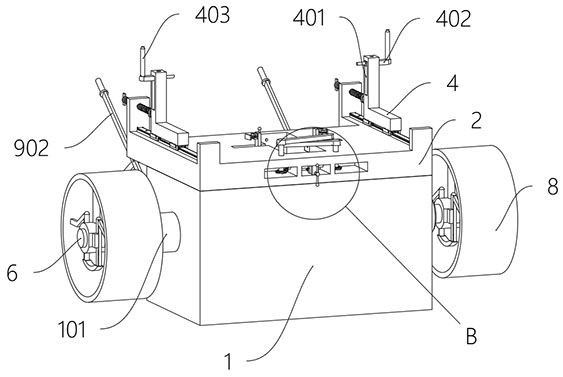

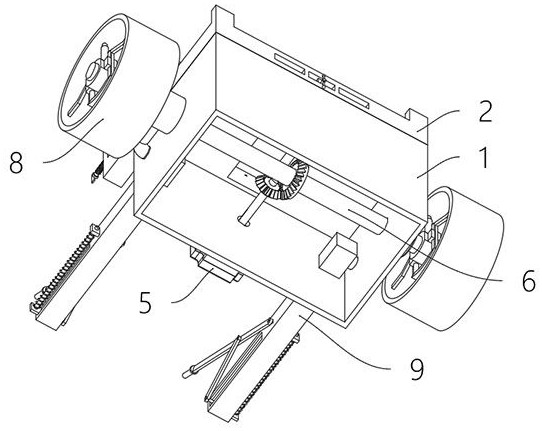

[0034] Example: Please refer to Figure 1 to Figure 9 :

[0035] The present invention proposes a suspension mechanism detection device based on automobile performance testing, comprising: a box body 1, two sets of bearing sleeves 101 are fixedly arranged in the middle of both sides of the box body 1; a top seat 2, and the top seat 2 is fixedly arranged on the box body 1, the middle of the top seat 2 is provided with a middle groove 201, and two sets of T-shaped slide grooves 202 are opened on both sides of the top of the middle groove 201; , T-shaped clamps 301 are hingedly arranged on the outside of the top of two groups of T-shaped chute 202; L-shaped sliding seat 4, the quantity of L-shaped sliding seat 4 is set to two groups, and two groups of L-shaped sliding seats 4 are set on the Both sides of the top of the box body 1; the motor 5, and the motor 5 are fixedly arranged in the middle of the front side of the box body 1; the test shaft 6, and the two ends of the test sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com