Device and method for calibrating elongated metallurgical tools based on laser ranging sensor

A technology of laser ranging and sensors, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult to achieve concentric coincidence, achieve high accuracy, good scientific performance, and ensure accurate and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

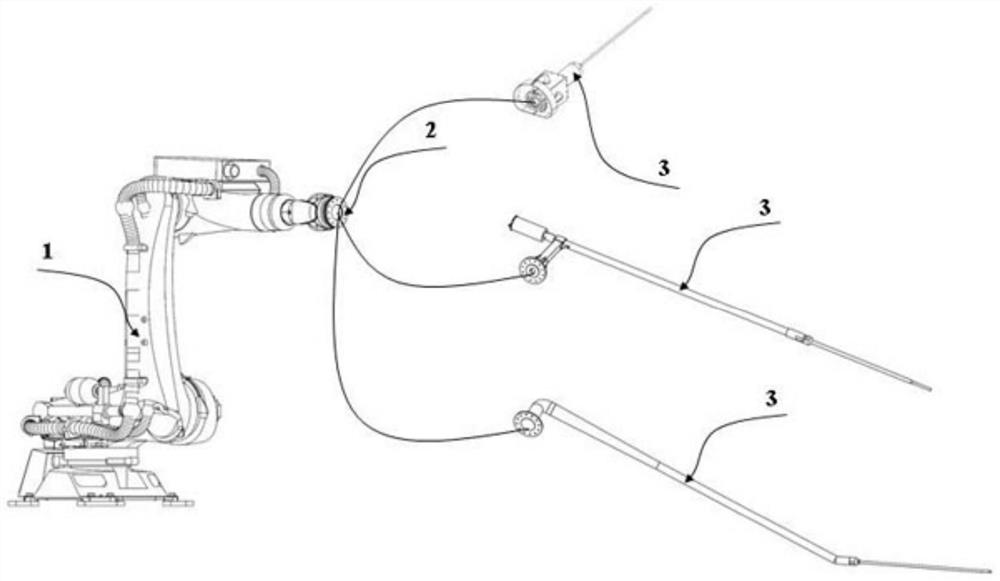

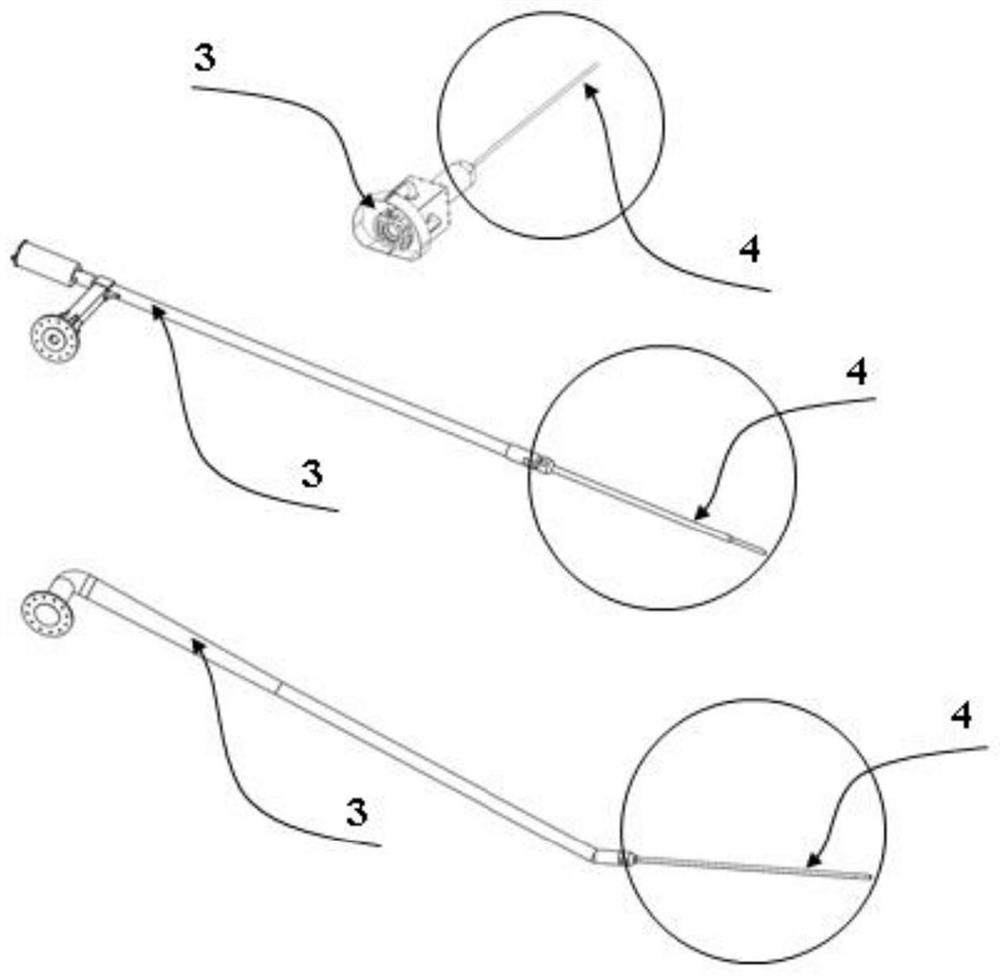

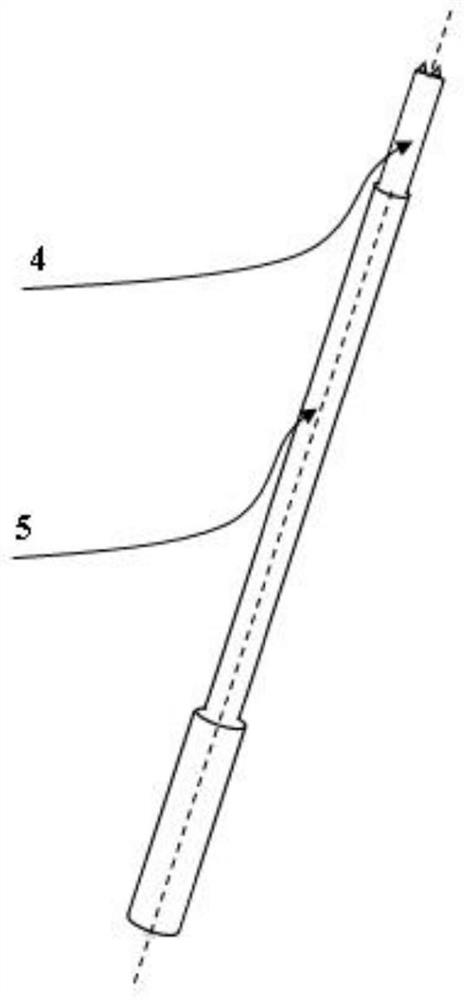

[0058] as attached Figure 1-4 As shown, in the prior art, the temperature measurement / sampling tool 3 is usually installed on the flange 2 at the end of the robot, has obvious slender characteristics, and can measure temperature / sampling as the robot 1 changes its position and posture. The front end of the sampling tool 3 is connected with a standard temperature measurement / sampling gun 4 through a thread. During the socket connection process of the probe 5 and the temperature measurement / sampling operation process, the main working part of the tool is the standard temperature measurement / sampling gun 4. In order to ensure The robot performs temperature measurement / sampling system operations accurately and stably.

[0059] This embodiment provides a device for calibrating elongated metallurgical tools based on a laser ranging sensor, and the calibration device includes a typical laser ranging sensor 6 and a calibration device 7 outside the laser ranging sensor 6 . Among them...

no. 2 example

[0085] as attached Figure 17 As shown, the second embodiment of the present invention is similar to the first embodiment with the following design changes. Based on the calibration device 7 of the laser ranging sensor 6, the calibration verification result is assisted in the process of the temperature measurement / sampling tool 3 moving to find the TCP point; the indication of the laser ranging sensor 6 can be used as the reliability of the axial calibration result and the deformation of the gun body quantity detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com