Environment-friendly mechanical wastewater purification device

A wastewater purification and mechanical technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., can solve the problems of difficult cleaning of filter cartridges and insufficient fine control of flocculant dosage, so as to improve the flocculation effect, Improve the purification efficiency and the effect of improving the purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

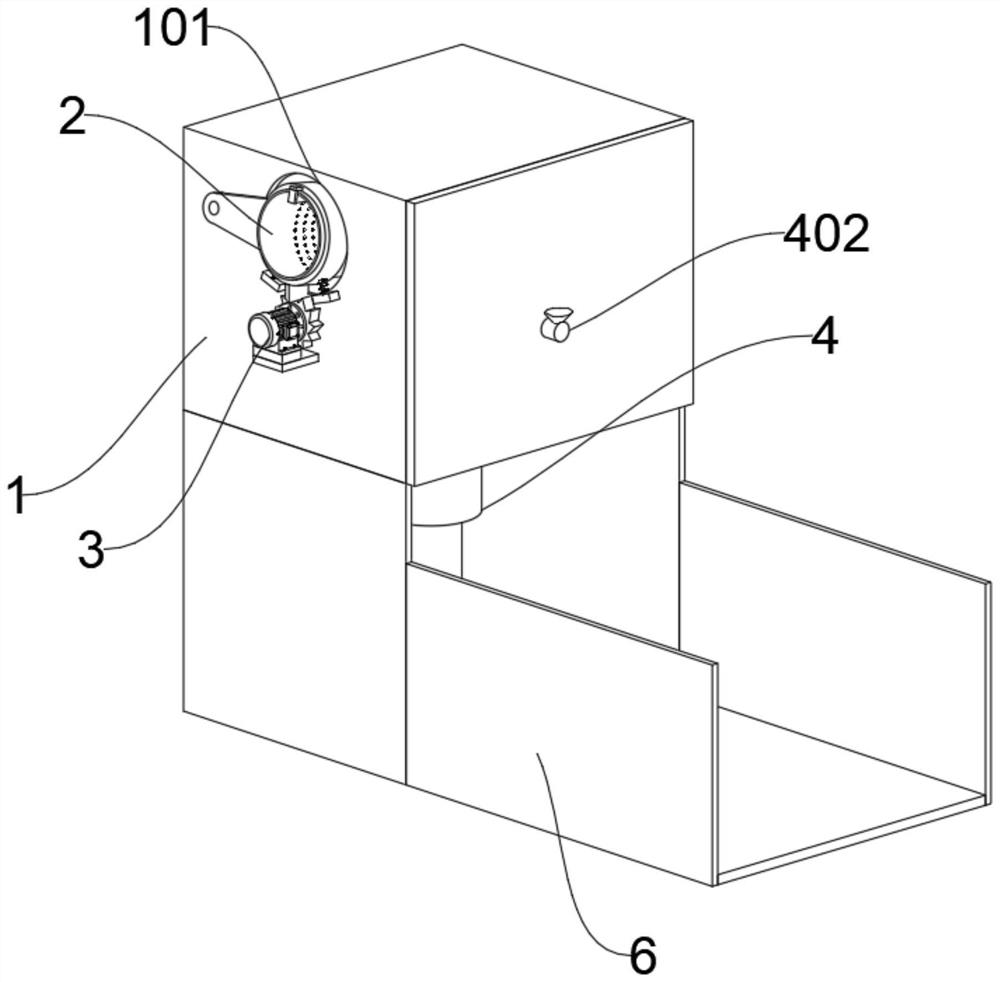

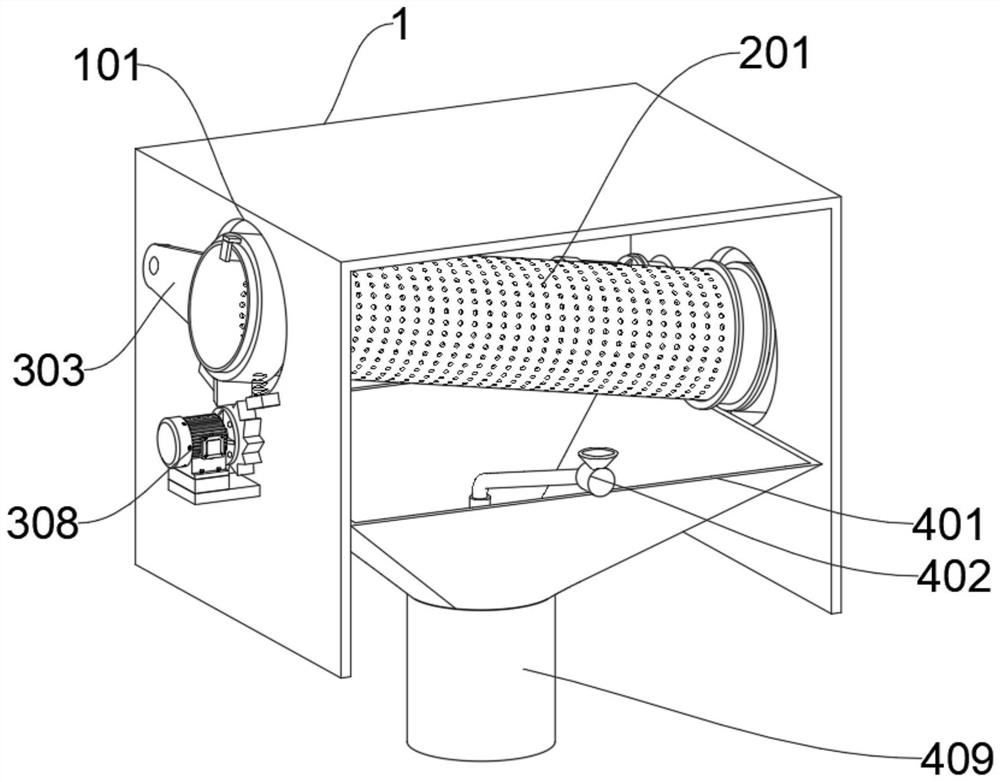

[0030] Please refer to Figure 1-3, an environmental protection mechanical wastewater purification device, including a housing 1, a fixing groove 101 is respectively opened at different heights on both sides of the housing 1, a filter cartridge 2 is arranged inside the housing 1, and the two ends of the filter cartridge 2 They run through the fixed grooves 101 on both sides respectively, and the bottom of the housing 1 is connected with a flocculation device 4, which is located under the filter cartridge 2, and a sedimentation tank 6 is set under the flocculation device 4, and a vibrating device 3 is connected under both ends of the filter cartridge 2 , The inside of the flocculation device 4 is provided with an automatic feeding device 5 .

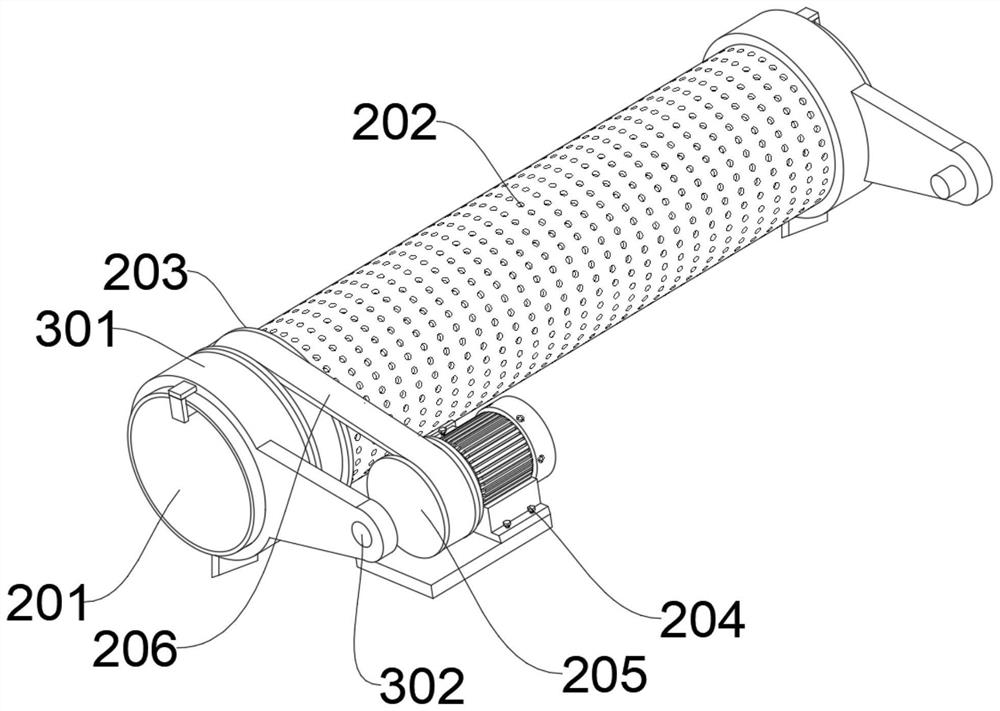

[0031] The filter cartridge 2 includes a cylinder body 201, the outer side of the cylinder body 201 is provided with a filter hole 202, the bottom outer side of the cylinder body 201 is fixedly set with a runner 203, and the inner wall of t...

Embodiment 2

[0035] Please refer to Figures 3-4, the difference in the basis of Embodiment 1 is that the filter cartridge 2 includes a cylinder body 201, the outer side of the cylinder body 201 is provided with a filter hole 202, and the outer bottom of the cylinder body 201 is fixedly sleeved with a rotary Wheel 203, a rotating motor 204 is screwed on the inner wall of the housing 1, and the output end of the rotating motor 204 is fixedly connected with a driving wheel 205, and the outer side of the driving wheel 205 and the running wheel 203 is provided with a belt 206, and the two are driven by belt 206 friction .

[0036] The vibration device 3 includes a fixing mechanism for fixing the cylinder 201 and a vibration mechanism for driving the vibration of the cylinder 201. The fixing mechanism includes two supporting swivels 301, and the two supporting swivels 301 are movably sleeved on both ends of the cylinder 201 respectively. On the outside, the outer side of the supporting swivel 30...

Embodiment 3

[0040] Please refer to Figures 5-6, the difference in the basis of Embodiments 1 and 2 is that the flocculation device 4 includes a water bucket 401, and the water bucket 401 is welded inside the shell 1, and the water bucket 401 is located in Below the barrel 201, a downpipe 409 is welded to the bottom of the downpipe 401, and a fixed bearing 408 is fixedly connected to the inner wall of the downpipe 409 through a support frame, and a casing 407 is sleeved inside the fixed bearing 408. , the top of the casing 407 is fixedly connected with a turbine 406, the inside of the turbine 406 is inserted with a rotating tube 405, the top of the rotating tube 405 is inserted with a connecting bearing 404, and the inside of the connecting bearing 404 is inserted There is a feed pipe 403 , the top of the feed pipe 403 is connected with a feed port 402 , and the feed port 402 is located at the front end of the casing 1 .

[0041] The automatic unloading device 5 includes a storage tube 501...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com