Method and system for determining pulse current in high-frequency pulse heating process of power battery

A power battery, high-frequency pulse technology, applied in battery/fuel cell control devices, electric vehicles, control drives, etc., can solve the problems of large layout space, low practicability, and low sampling frequency of current acquisition equipment, and achieve improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

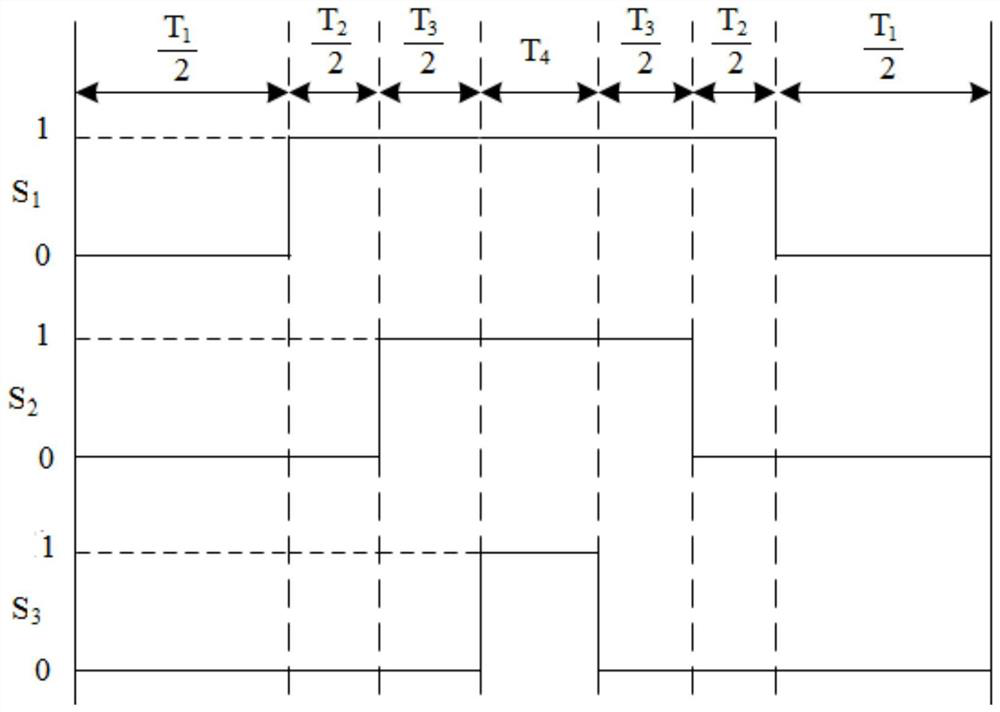

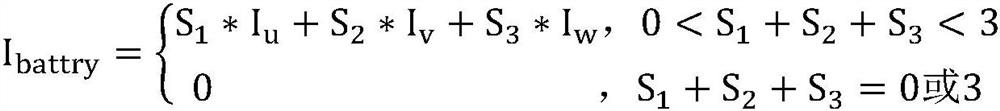

[0019] like figure 1 As shown, the pulse current determination system during the high-frequency pulse heating process of the power battery includes a motor controller, and the motor controller includes a control module (not shown in the figure), a three-phase bridge arm and a bus capacitor C. The three-phase bridge arm is composed of a U-phase bridge arm, a V-phase bridge arm and a W-phase bridge arm connected in parallel, and the bus capacitor C is connected in parallel with the U-phase bridge arm, V-phase bridge arm and W-phase bridge arm. The U phase bridge arm is controlled by the upper bridge arm power switch K 1 and the power switch K of the lower bridge arm 4 connected, the V-phase bridge arm is composed of the upper bridge arm power switch K 2 and the low-side power switch K 5 The W phase bridge arm is composed of the upper bridge arm power switch K 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com