A vacuum homogeneous emulsifier

A technology of vacuum homogenization and emulsification machine, applied in the direction of mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of waste, pollution, easy to breed bacteria, etc., and achieve the effect of avoiding oxidation or pollution and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

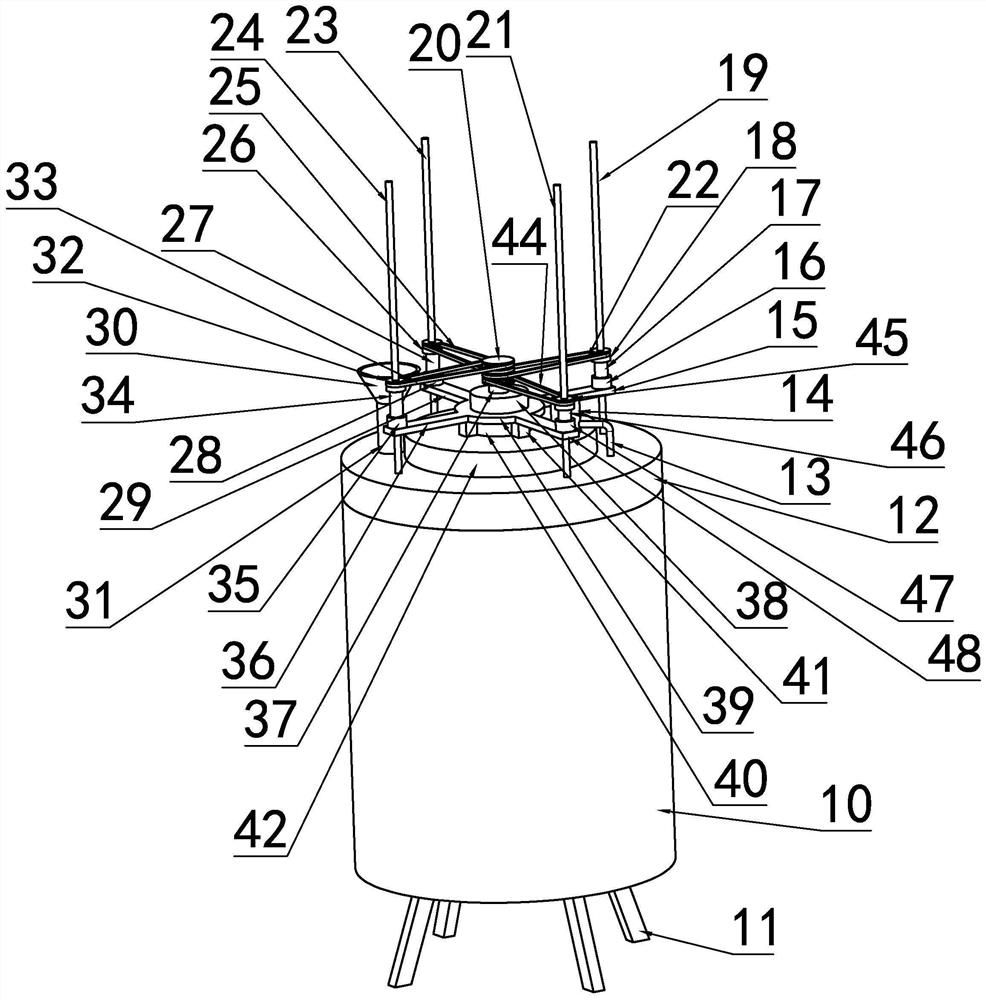

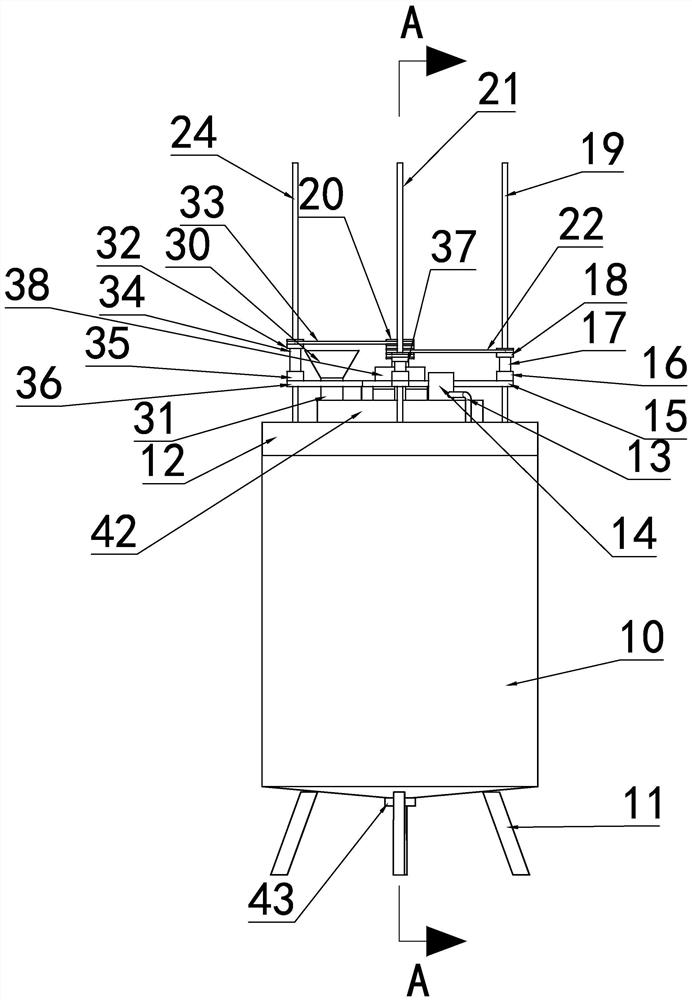

[0026] Such as figure 1 with figure 2 As shown, a vacuum homogeneous emulsifier includes a housing 10, four housing support columns 11 are fixedly arranged on the lower side of the housing 10, a discharge port 43 is fixedly arranged on the lower side of the housing 10, and an upper side of the housing 10 Fixedly be provided with loam cake 12, loam cake 12 upper side is fixedly provided with rotary motor limiting cover 42, loam cake 12 upper side is fixedly provided with feed pipe 31, and feed pipe 31 upper side is fixedly provided with feed inlet 30, loam cake 12 upper side is fixedly provided with suction pipe 13.

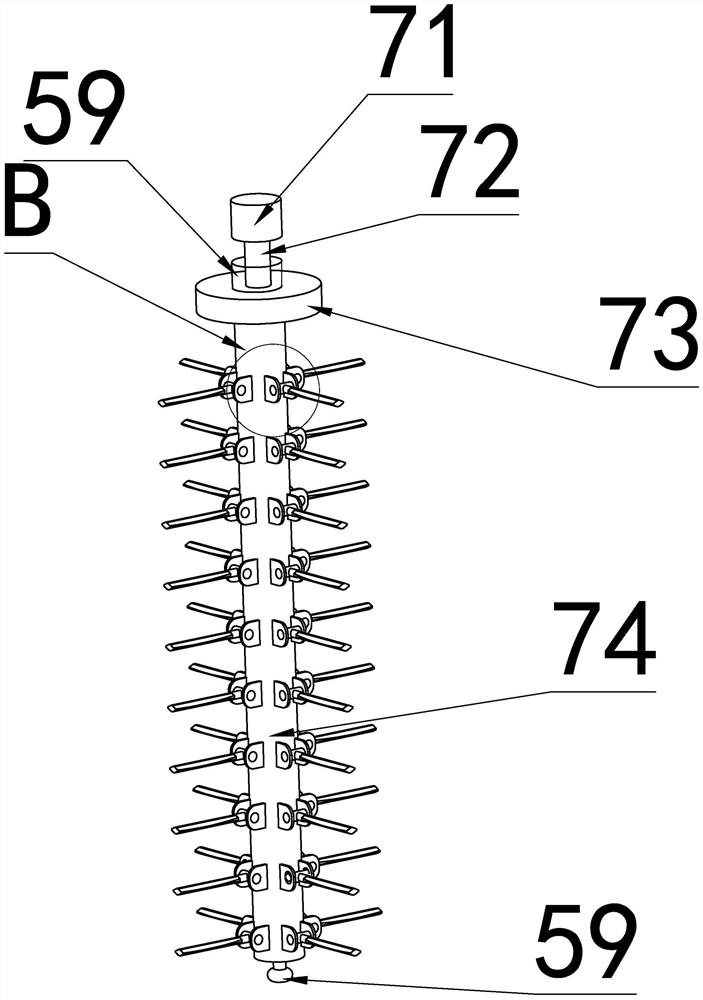

[0027] Such as figure 1 with Figure 5 As shown, the upper side of the rotating motor limit cover 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com