Sealing structure of junction box of electromagnetic flowmeter

A technology of electromagnetic flowmeter and sealing structure, which is applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, volume measurement, etc., which can solve unfavorable electromagnetic flowmeter installation and daily maintenance work, and affect electromagnetic flow Problems such as the stability and reliability of meter equipment, the entry of polluting gases, solid particles, and seepage, etc., to achieve the effects of installation positioning and electrical connection, convenience, stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the implementation of the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further elaborated below in conjunction with specific embodiments.

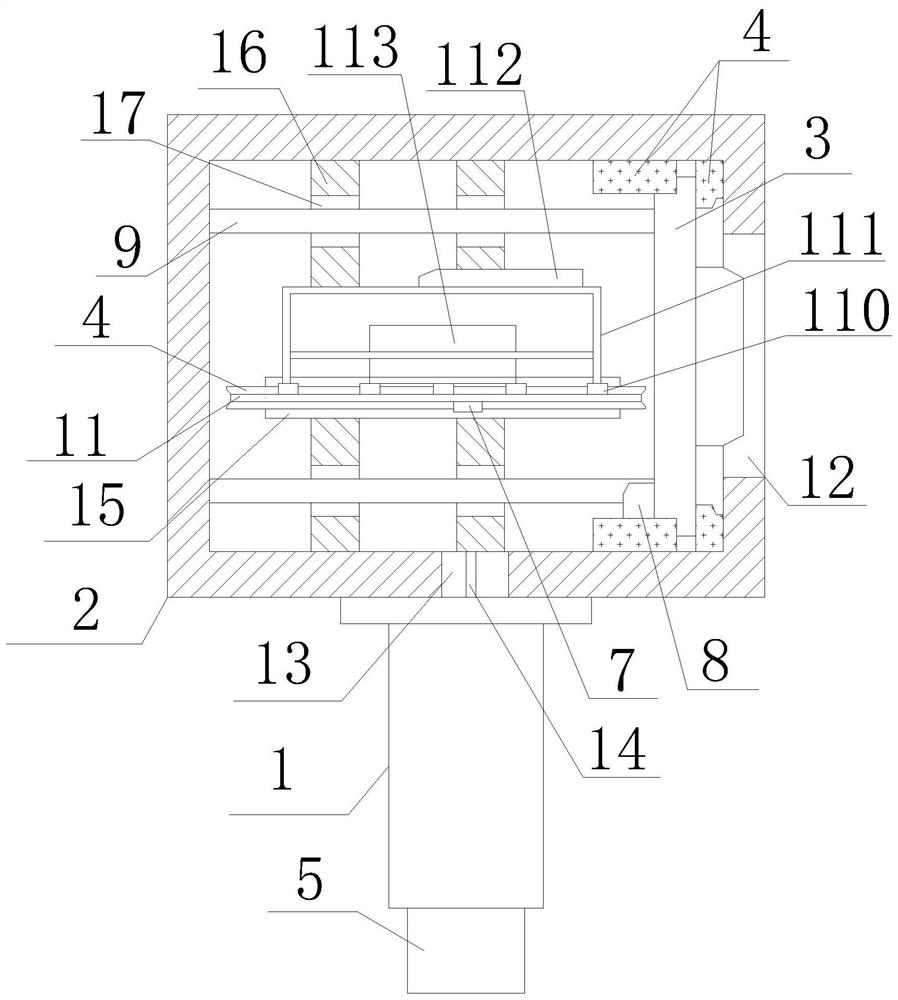

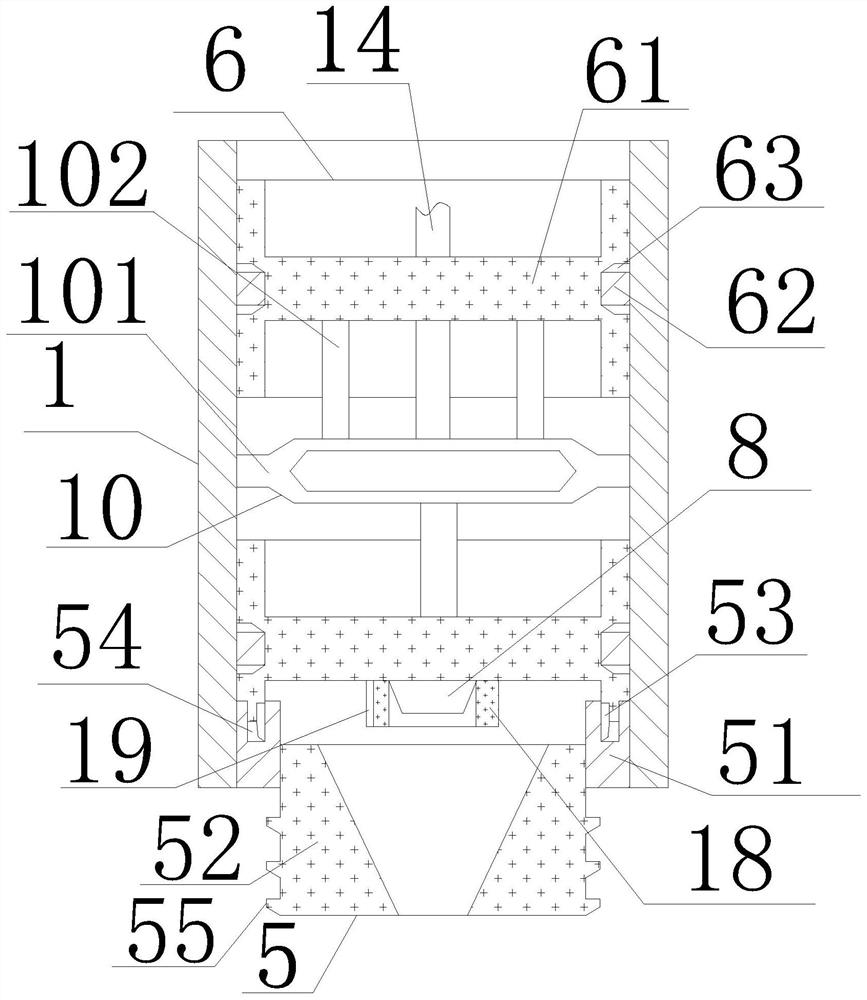

[0019] Such as figure 1 and 2 As shown, a sealing structure of an electromagnetic flowmeter junction box includes a bearing column 1, a bearing box body 2, a control panel 3, a sealing ring 4, a sealing column 5, a sealing plate 6, a main terminal 7, an auxiliary terminal 8, a bearing The spring 9, the positioning spring 10 and the bearing plate 11, wherein the bearing column 1 is a hollow tubular structure with a rectangular axial section, and its upper end surface is connected with the end surface of the bearing box body 2 through a sealed thread, and the axis of the bearing column 1 is connected to the bearing box. The axis of the body 2 is vertically distributed, and the carrying box body 2 is a closed cavity structure with a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com