Separation and preparation device for construction waste regenerated micro powder

A technology of regenerated micropowder and preparation equipment, which is applied in the direction of solid separation, sieve, grid, etc., which can solve the problems of slowing down the preparation speed of construction waste regenerated micropowder and obstruction of powder filtration, so as to maintain smooth flow, speed up the speed and speed up the preparation The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

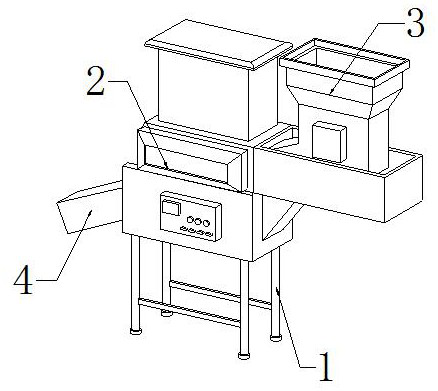

[0029] as attached figure 1 to attach Image 6 Shown:

[0030] The invention provides a device for separating and preparing construction waste regenerated micropowder. Its structure includes a support 1, a body 2, a feed hopper 3, and a discharge hopper 4. The end is installed on the top of the body 2 near the right end, and the right end of the discharge hopper 4 is obliquely fixed on the left side surface of the body 2 .

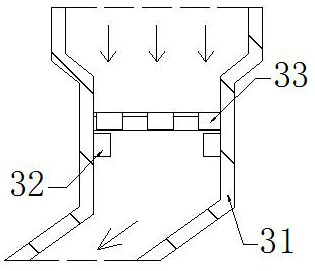

[0031] The feed hopper 3 includes a housing 31, a push mechanism 32, and a filter plate 33. The push mechanism 32 is respectively installed on the inner walls of the left and right sides of the housing 31, and the bottom surfaces of the left and right ends of the filter plate 33 lean against the push mechanism 32. upper surface.

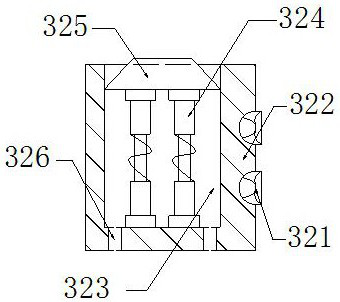

[0032] Wherein, the pushing mechanism 32 includes an elastic block 321, a frame 322, a movable chamber 323, a push rod 324, a push plate 325, and a discharge port 326, and the right side of the frame 322 is connected with the ...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] Wherein, the discharge port 326 includes a sleeve 26a, a clamping plate 26b, and a movable ball 26c, and the clamping plate 26b is installed on the inner walls of the left and right sides of the bottom end of the sleeve 26a respectively, and the movable ball 26c is placed on the clamping plate 26b On the inner side, there are four movable balls 26c, which are symmetrically distributed from left to right. The dynamic power is generated by the up and down jumping of the movable balls 26c, so that the clamping plate 26b is shaken back and forth under the action of power, and the powder attached to the outer surface of the clamping plate 26b is accelerated to shake and fall. .

[0041] Wherein, the clamping plate 26b includes a telescopic block b1, a support plate b2, and a magnetic block b3. On the right side of the support plate b2, the magnetic force of the magnetic block b3 on the left and right sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com