Method for manufacturingflexible stretchable battery pack

A manufacturing method and battery pack technology, which are applied to battery pack components, isolation of batteries from their environment, circuits, etc., can solve the problems of limited bending times, low safety, and inability to stretch and twist, achieving good safety and improving safety. wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An embodiment of the present invention provides a method for manufacturing a flexible and stretchable battery pack, which includes:

[0060] Process 1, the manufacturing steps of the internal cell module, including:

[0061] Place each cell in the mold and inject glue into the cell to form a cell glue injection layer; the cell is packaged in the cell glue injection layer to form an island structure, and one side of the island structure (not covered by the cell glue injection layer) reserved for electrical connection (electrical connection with the PCB board or other cells) adapter plate (circuit expansion interface), the adapter plate through the wire as a bridge and The cells are electrically connected to form an island bridge structure; wherein the cell glue injection layer does not include the side where the cells are located on the adapter plate;

[0062] Place each PCB board in the mold and inject glue into the PCB board to form a PCB board glue injection layer; ...

Embodiment 2

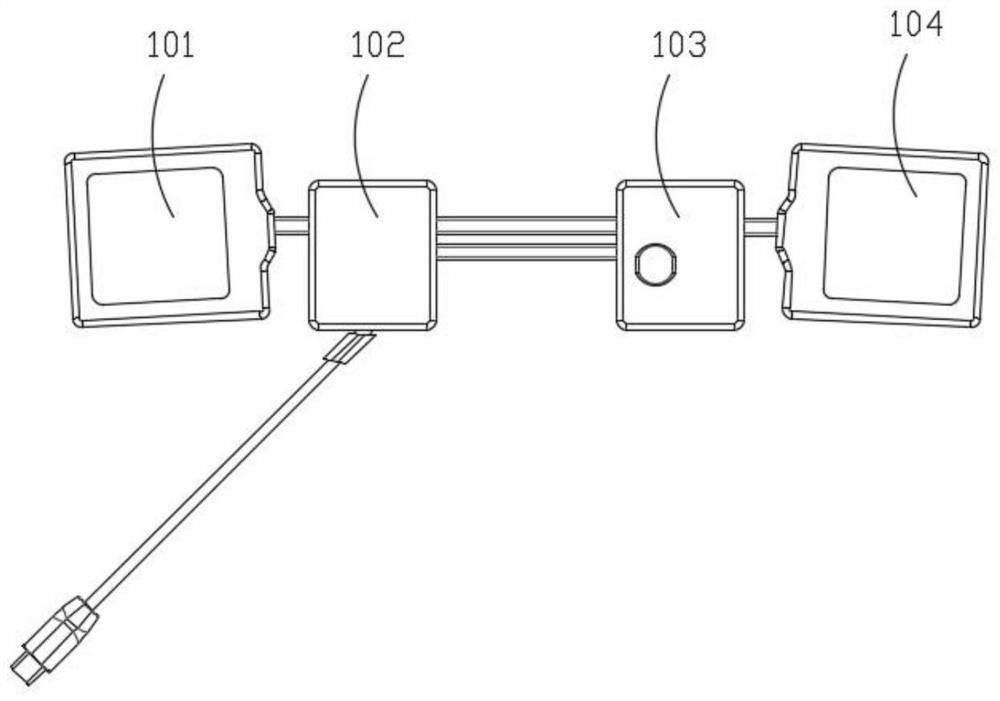

[0072] see Figure 4 , in this embodiment, the internal cell module 100 is a symmetrical structure, which includes a third cell 111, a first PCB board 112, a second PCB board 113, and a fourth cell 114 placed in sequence, and the third cell 111 It is electrically connected to the first PCB board 112, the second PCB board 113 is electrically connected to the fourth electric core 114, the first PCB board 112 and the second PCB board 113 are electrically connected to each other, the first PCB board 112 with the glue injection layer and the The shape and size of the second PCB board 113 of the glue injection layer are basically the same (the size of the first PCB board 112 and the second PCB board 113 in the glue injection layer can be the same or different, and it can be determined by the thickness of the glue injection layer. Appropriately adjusted), so that the internal cell module 100 forms a left-right symmetrical structure centered on the middle.

[0073] See Figure 5-Fig...

Embodiment 3

[0081] In this embodiment, different from Embodiment 1 and Embodiment 2, the internal cell module also includes two electrical connectors (the number of which can be set according to actual needs) electrically connected to each cell and the PCB board. see Figure 16 , the internal cell module 100 includes a fifth cell 131, a third PCB board 132, a fourth PCB board 133, a sixth cell 134, a first electrical connector 135, and a second electrical connector 136 placed in sequence. The five electric cores 131 are electrically connected to the third PCB board 132, the fourth PCB board 133 is electrically connected to the sixth electric core 134, the third PCB board 132 and the fourth PCB board 133 are electrically connected to each other, and the first electrical connector 135 is connected to the sixth electric core 134. The three PCB boards 132 are electrically connected, and the second electrical connector 136 is electrically connected to the fourth PCB board 133 . The shape of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com