Construction method for laying ceramic tiles in arc-shaped space

A construction method and ceramic tile technology, which is applied in the direction of architecture and building construction, etc., can solve problems such as low construction efficiency, increased labor costs, and small specifications of mosaic tiles, so as to increase the laying area, improve construction efficiency, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

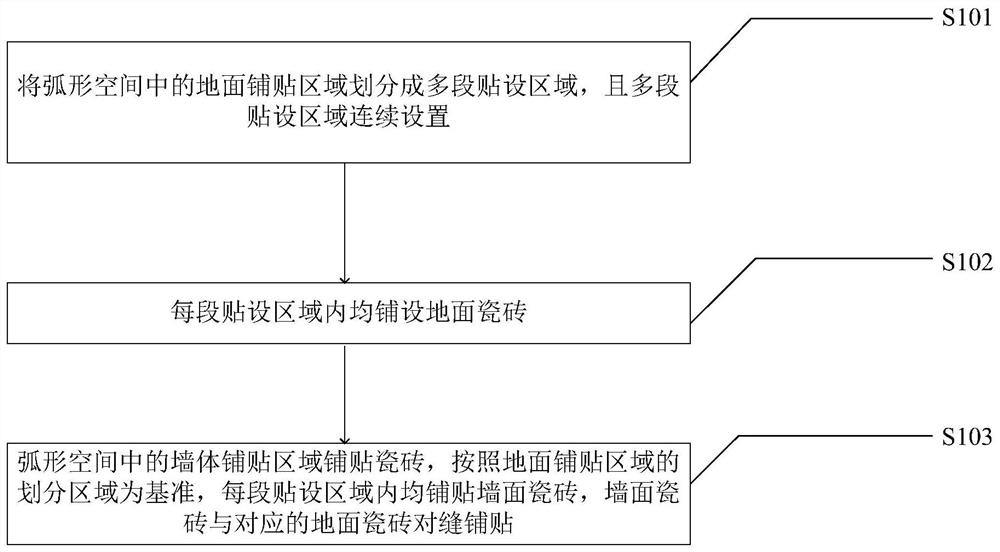

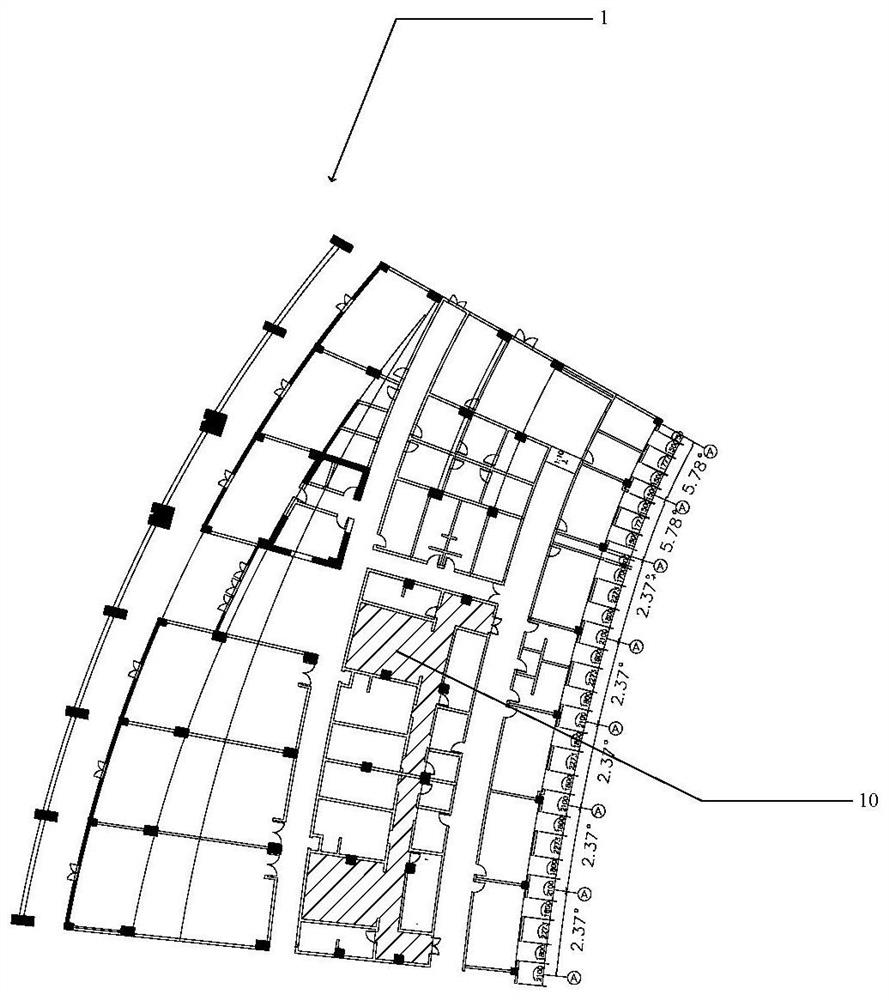

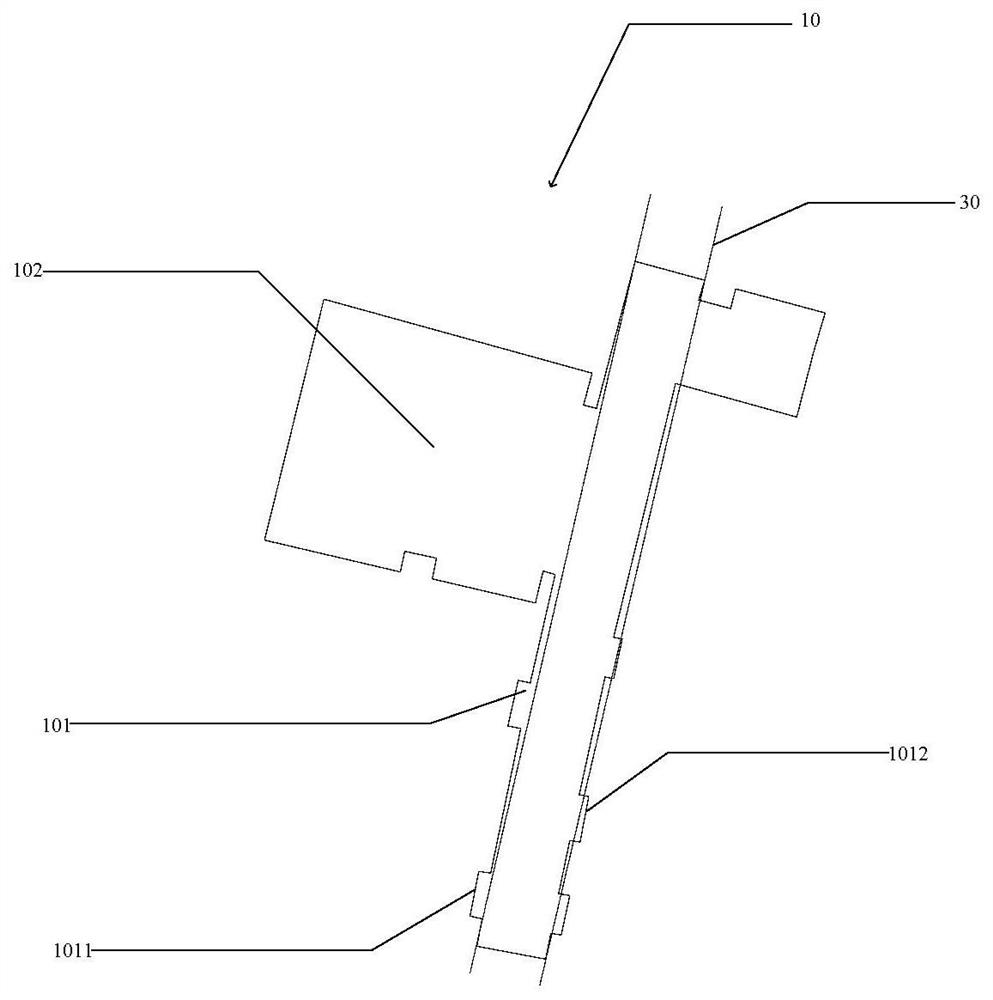

[0028] refer to figure 1 with Figure 4 , which is a construction method for laying tiles in arc-shaped space disclosed by the present invention, the construction method comprises the following steps:

[0029] S101. Divide the floor laying area 102 in the arc space 1 into multiple laying areas 20, and the multiple laying areas 20 are arranged continuously.

[0030] Specifically, the ground laying area 102 is divided into multiple laying areas 20 by adopting the "circle cutting technique" of "substituting straight lines for curves". It should be noted that the "circle cutting technique" cuts a circle by inscribed regular polygons, and makes the perimeter of the regular polygon infinitely close to the perimeter of the circle, so as to obtain a more accurate ratio of pi.

[0031] Among them, according to the "circle cutting technique", each section of the pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com