Automatic discharging frame

A technology of automatic feeding and main frame, which is applied in thin material processing, coiling, transportation and packaging, etc. It can solve the problems of less tension, failure to use normally, labor occupation and other problems, and achieve uniform tension , save manpower, eliminate the effect of manual feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

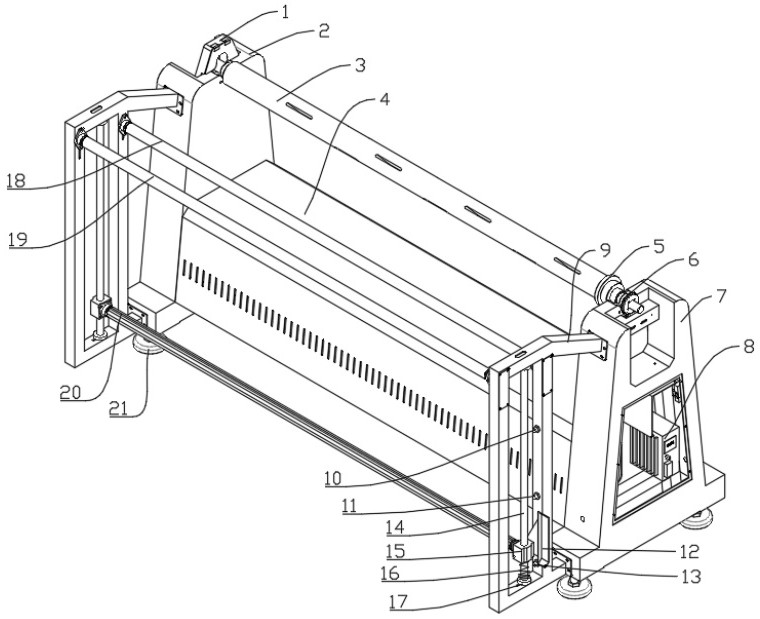

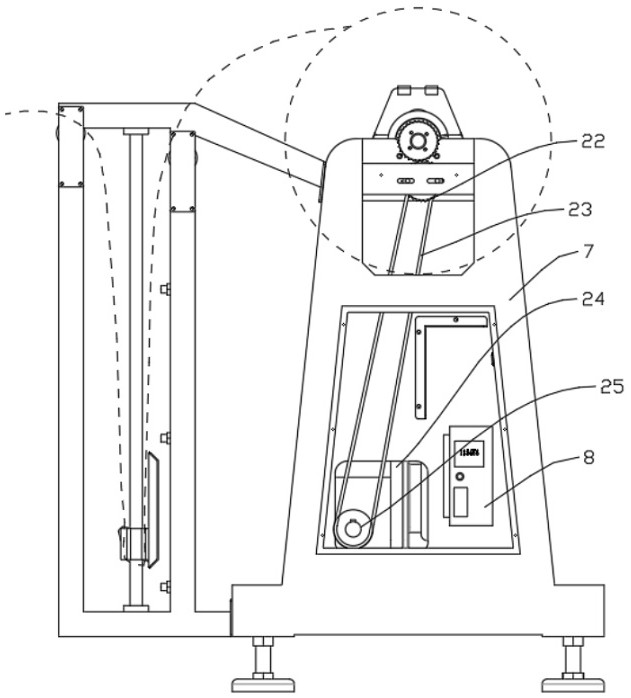

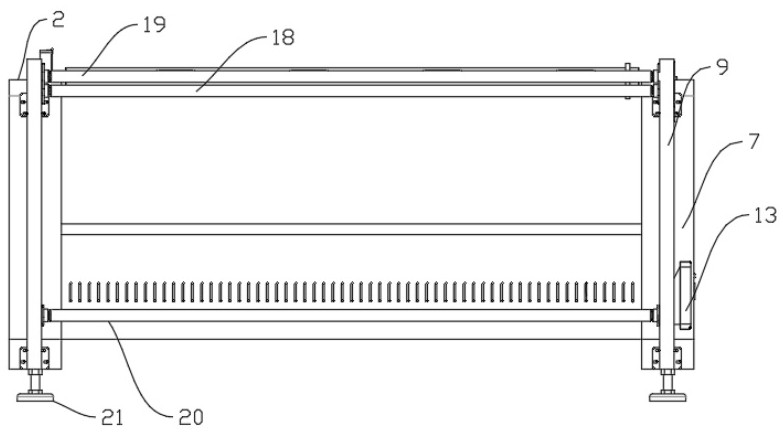

[0025] refer to Figure 1-3 , a kind of automatic unwinding frame, comprises main frame left support 2 and main frame 4, main frame left support 2 and main frame 4 are fixedly connected by welding, main frame 4 right side is welded with main frame right support 7, main frame The bottoms of the left support 2 and the right support 7 of the main frame are respectively connected by bolts with two adjustment feet 21, and the two adjustment feet 21 on the left and right sides are symmetrically distributed, and a control computer 8 is arranged inside the lower side of the right support 7 of the main frame;

[0026] A protective cover 1 is fixedly connected to the left support 2 of the main frame, and an inflatable shaft 3 is placed in the protective cover 1 and the left support 2 of the main frame. The right side is provided with a driven gear 6, and the driven gear 6 is fixedly sleeved on the right end of the inflatable shaft 3, and the right support 7 of the main frame is connecte...

Embodiment 2

[0035] refer to Figure 1-3 , an automatic unwinding rack. In the specific implementation process, the flower-shaped toothed roller is used as the material tensioning shaft 20, which can have a leveling effect on the material when rolling, and the middle wrinkle phenomenon of the material can be rolled under the bevel tooth surface. , to level the material, which plays an important role in the later processing and precision;

[0036]The invention reduces the tensile force on the material when the material is sorted, ensures that the material is always in a state of flatness and less tension when unloading, eliminates the manual unloading operation, and saves a lot of manpower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com