A kind of battery quick change device of electric logistics vehicle

A technology for quick battery replacement and logistics vehicles, which is applied in the direction of electric power units, power units, electric vehicles, etc., which can solve the problems of troublesome battery replacement, inconvenient installation, and inconvenient installation of battery replacement solutions, saving time and improving operational efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

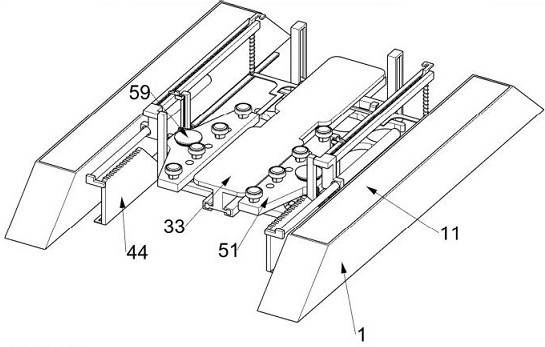

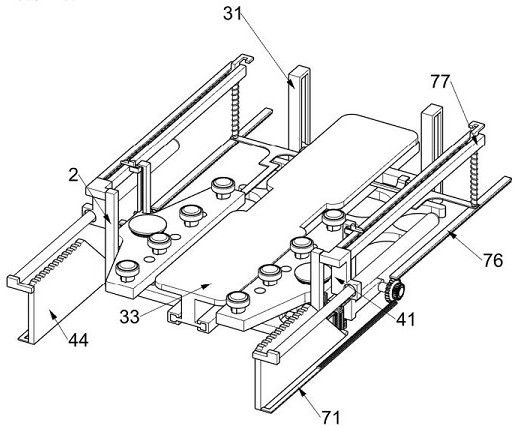

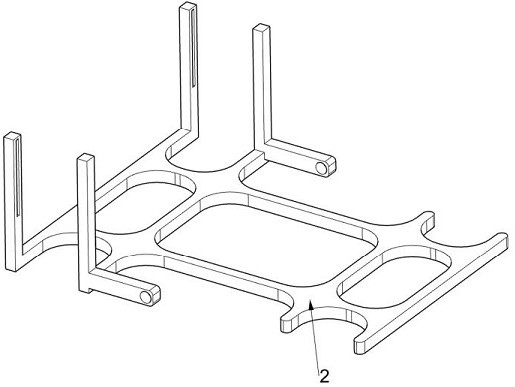

[0047] A battery quick-change device for an electric logistics vehicle, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 and 19 As shown, it includes a wheel frame 1, a special-shaped support base plate 2, a lifting assembly 3, a push assembly 4, a bolt removal assembly 5, a bolt installation assembly 6 and a push-pull assembly 7. The two wheel frames 1 are fixedly installed on the ground, and the special-shaped support base plate 2 The lifting component 3 is symmetrically arranged on the upper part, the pushing component 4 is symmetrically arranged on the special-shaped supporting bottom plate 2, and the bolt disassembling component 5 is symmetrically and slidingly connected on the special-shaped supporting bottom plate 2, and the bolt disassembling component 5 is used t...

Embodiment 2

[0058] On the basis of Example 1, as Figure 15 , Figure 16 and Figure 17 As shown, it also includes a reset assembly 8, a reset assembly 8 for reset is provided on one side of the rectangular slide rail frame 77, and the reset assembly 8 includes a second return spring 81, a rectangular slotted frame 82, a wedge-shaped card frame 83, a first A return spring 84 and a second return spring 85, a second return spring 81 is connected between the special-shaped rack frame 76 and the rectangular slide rail frame 77, and the second return spring 81 is used to drive the special-shaped rack frame 76 and its upper The device moves and resets in the direction away from the special-shaped support frame 41. A rectangular slotted frame 82 is fixedly installed on one side of the rectangular slide rail frame 77. The rectangular slotted frame 82 is used to clamp the special-shaped rack frame 76, and the wedge-shaped card frame 83 is slidingly connected. On the rectangular slotted frame 82,...

Embodiment 3

[0061] On the basis of Example 2, as Figure 18 As shown, it also includes a circular arc angle 10, a limit slot 9 is opened on the wedge-shaped push frame 44 in a uniform arrangement, and the limit slot 9 is used to limit the special-shaped sliding frame 63 and its upper device. The limit slot 9 Both sides are provided with arc angles 10 , and the arc angles 10 are convenient to push the special-shaped sliding frame 63 to move above the wedge-shaped push frame 44 .

[0062] Through the action of the limiting slot 9 and the arc angle 10, when the special-shaped sliding frame 63 and its upper device are pushed to move above the wedge-shaped pushing frame 44, the special-shaped sliding frame 63 and its upper device can be limited to avoid the special-shaped sliding frame 63 and its upper device. 63 and the position of the device on it are shifted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com