Multi-connecting-rod vehicle-mounted lifting platform

A multi-link and platform technology, applied in hoisting devices, safety devices of lifting equipment, cranes, etc., can solve problems such as limited application scope, and achieve the effects of easy manufacturing, reasonable design and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

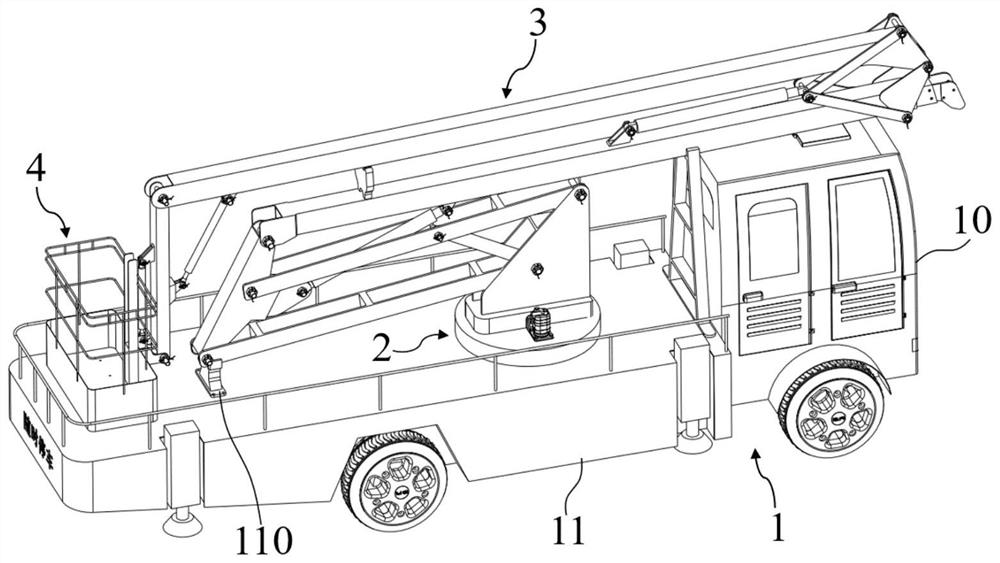

[0063] The multi-link vehicle-mounted lifting platform of this embodiment includes:

[0064] Car body 1, which includes a headstock 10 and a loading platform 11 connected to the headstock 10;

[0065] The slewing unit 2 is arranged on the top surface of the loading platform 11 and performs slewing driving action;

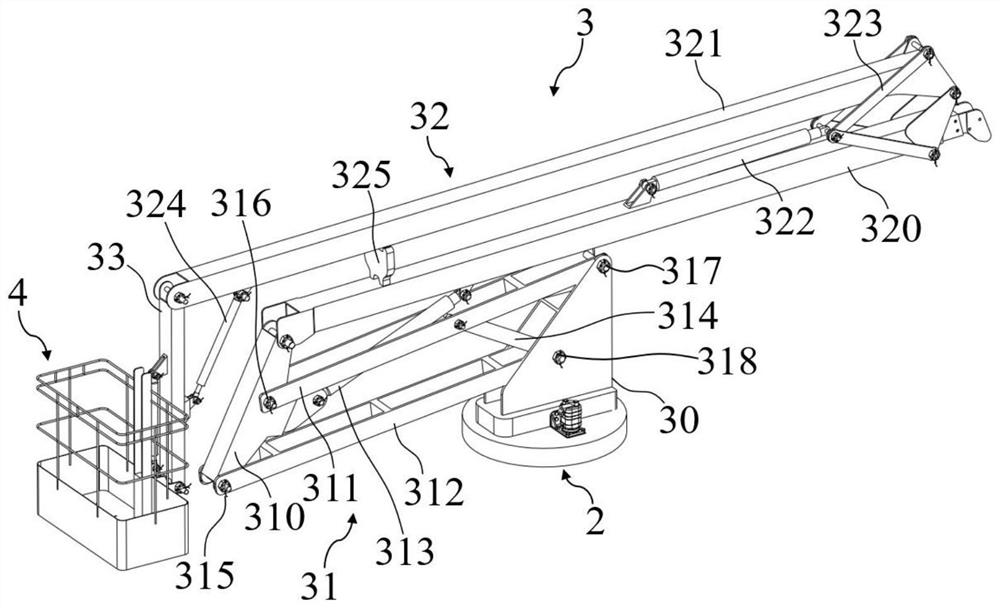

[0066] Lifting unit 3, which includes a base 30, a primary lifting mechanism 31, a secondary lifting arm 32 and a working folding arm 33 that are sequentially connected by transmission;

[0067] The bottom of the base 30 is connected to the top of the rotary unit 2 by transmission;

[0068] Described primary lifting mechanism 31 comprises mechanism main arm 310, mechanism connecting arm one 311, mechanism connecting arm two 312, first hydraulic cylinder 313 and second hydraulic cylinder 314; The top of mechanism main arm 310 and secondary lifting arm 32 is hinged; one end of mechanism connecting arm one 311 is hinged with the middle part of mechanism main arm 310,...

Embodiment 2

[0076] The multi-link vehicle-mounted lifting platform of this embodiment is further improved on the basis of Embodiment 1. In the first-level lifting mechanism 31:

[0077] A protrusion 3100 is formed in the middle of the main arm 310 of the mechanism, and the protrusion 3100 is arranged toward the base 30 ;

[0078] Mechanism connecting arm one 311 is H-shaped, including two side arm plates 3110 arranged parallel to each other and a connecting arm plate 3111 placed between the two side arm plates 3110 to connect the two side arm plates 3110;

[0079] One end of the first hydraulic cylinder 313 is hinged to the raised portion 3100 , and the other end passes through the gap between the arm plates 3110 on both sides and protrudes upwards to be hinged to the secondary lifting arm 32 .

[0080] Such as Figure 4 As shown, the main arm 310 of the mechanism in this embodiment is T-shaped, and the whole structure is welded and spliced. It bears all the normal pressure and overturni...

Embodiment 3

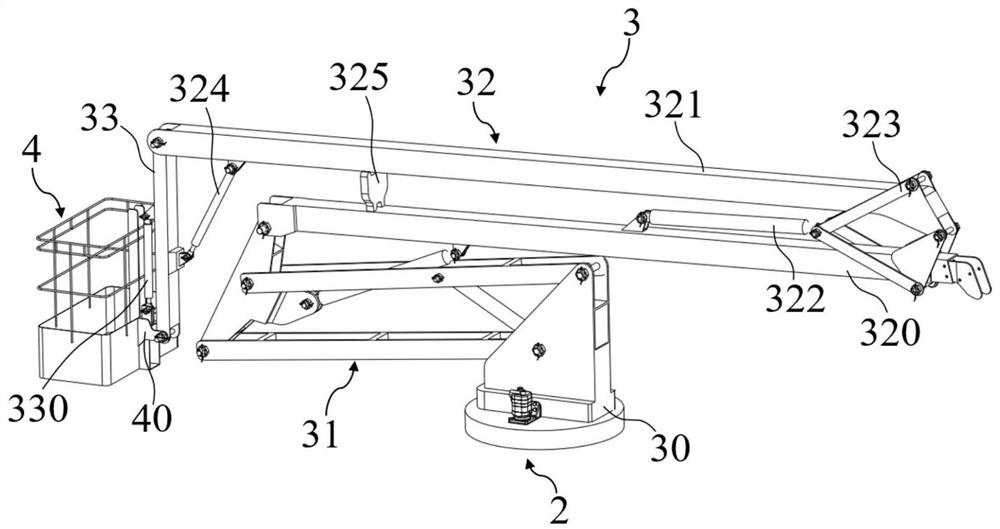

[0082] The multi-link vehicle-mounted lifting platform of this embodiment is further improved on the basis of Embodiments 1 and 2, and the secondary lifting arm 32 includes:

[0083] Lifting the main arm 320, one end of which is hinged to the top of the mechanism main arm 310, and the first hydraulic cylinder 313 is hinged to the bottom of the middle part of the lifting main arm 320;

[0084] Lifting auxiliary arm 321, one end of which is hinged to the other end of lifting main arm 320, and the other end is hinged to one end of working folding arm 33;

[0085] The third hydraulic cylinder 322, one end of which is hinged to the top of the lifting main arm 320, and the other end is in transmission connection with the lifting auxiliary arm 321;

[0086] One end of the fourth hydraulic cylinder 324 is hinged to the bottom of the lifting auxiliary arm 321 , and the other end is hinged to the working folding arm 33 .

[0087] Such as figure 2 with image 3 As shown, the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com