Automatic solid impurity separation device for wastewater pretreatment

A technology for automatic separation of solid impurities, applied in filtration separation, separation methods, moving filter element filters, etc., can solve the problems of wasting manpower, affecting filtration efficiency, clogging, etc., and achieve the effect of reducing the rate of sediment backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

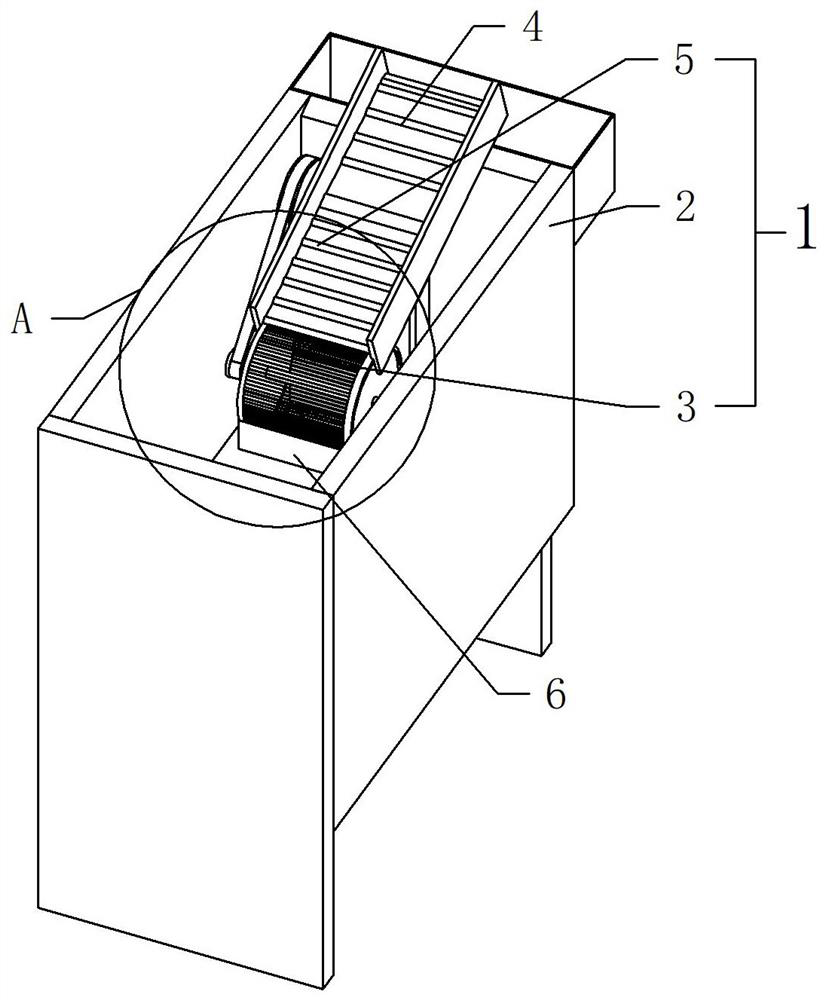

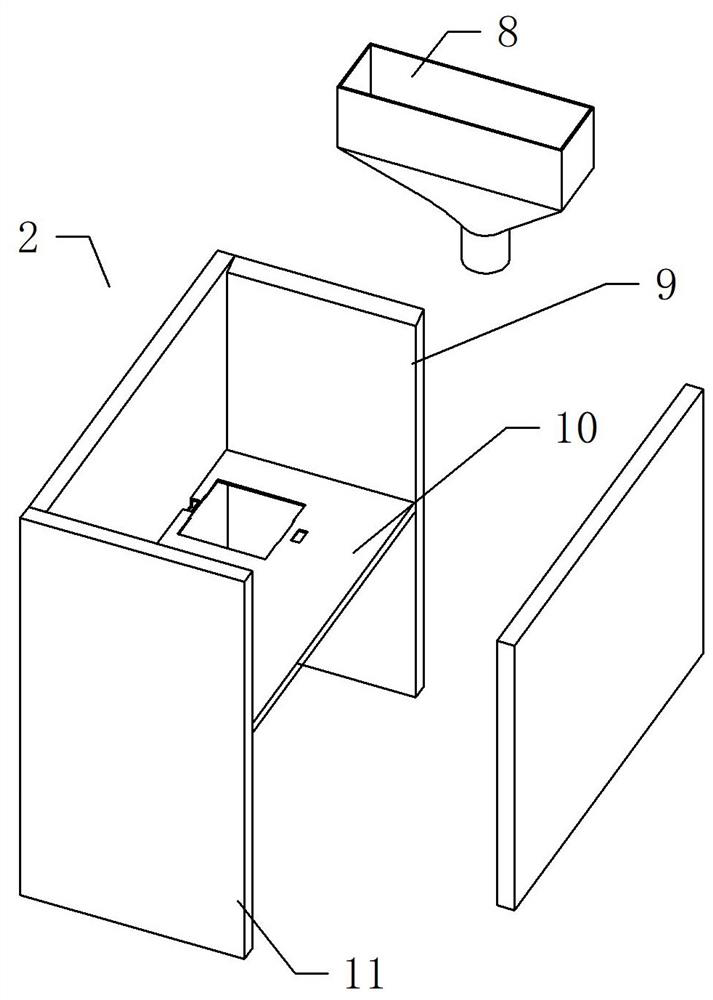

[0029] Example: as attached Figures 1 to 8 As shown, an automatic solid impurity separation device for wastewater preparatory treatment includes a solid impurity cleaning mechanism 1. The solid impurity cleaning mechanism 1 includes a reservoir 2, a filter body 3, a guide body 5 and a power body 7. The filter body 3 and the storage body The pool 2 is rotated and installed together, and the guide body 5 is fixedly connected with the reservoir 2; the reservoir 2 includes a pool body 9, an isolation plate 10 and supporting legs 11, and the isolation plate 10 is fixedly connected with the pool body 9, A pair of supporting legs 11 are provided, and the supporting legs 11 are fixedly connected with the pool body 9 .

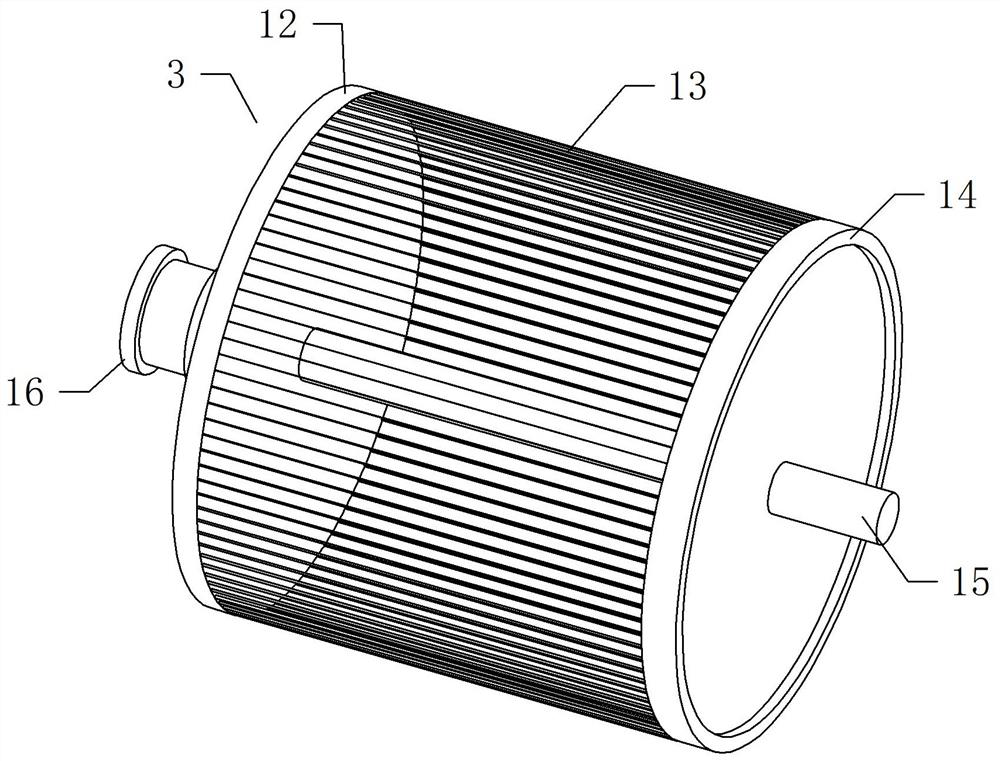

[0030] The filter main body 3 includes a swivel seat 12, a filter screen 13, a gear ring 14, a first rotating shaft 15 and a pulley 16, the first rotating shaft 15 is connected to the pool body 9 in rotation, the swivel seat 12 is provided with a pair, and the swivel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com