Full-automatic milk tea making equipment

A fully automatic, milk tea technology, applied in the direction of beverage preparation devices, coin-operated equipment for dispensing discrete items, coin-operated equipment for controlling the distribution of fluid/granular materials from containers, etc., which can solve the problem of inability to guarantee solid and liquid The ratio is uniform, it cannot adapt to the quantitative feeding of coconut fruit particles or pearl particles, and the quality control of milk tea has a great impact, so as to reduce manual participation, add accurate dosage, and reduce the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

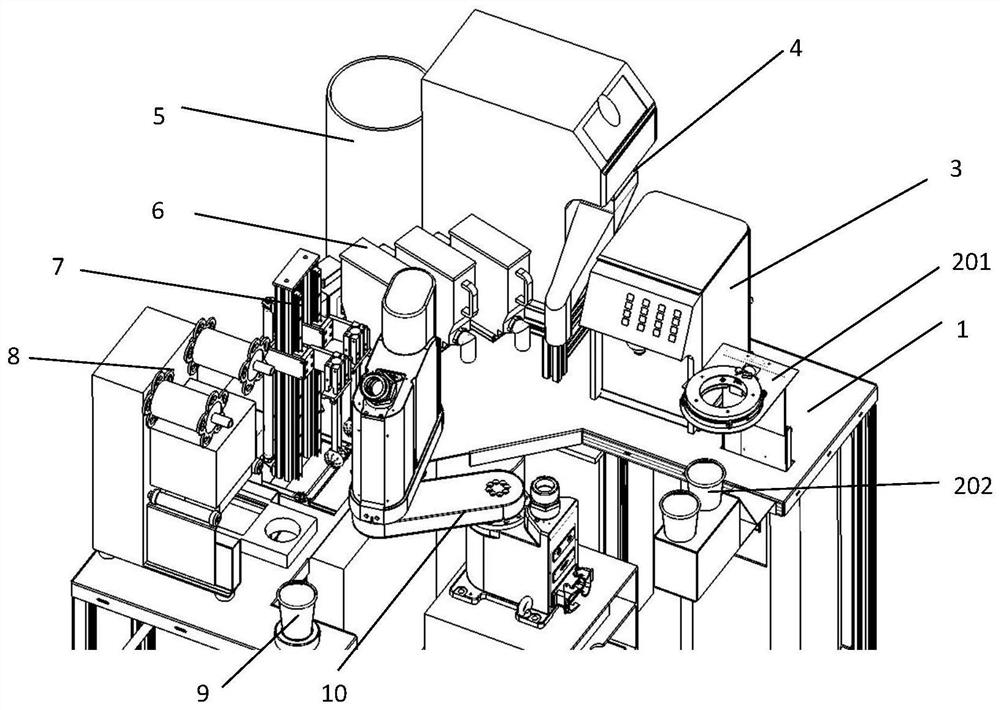

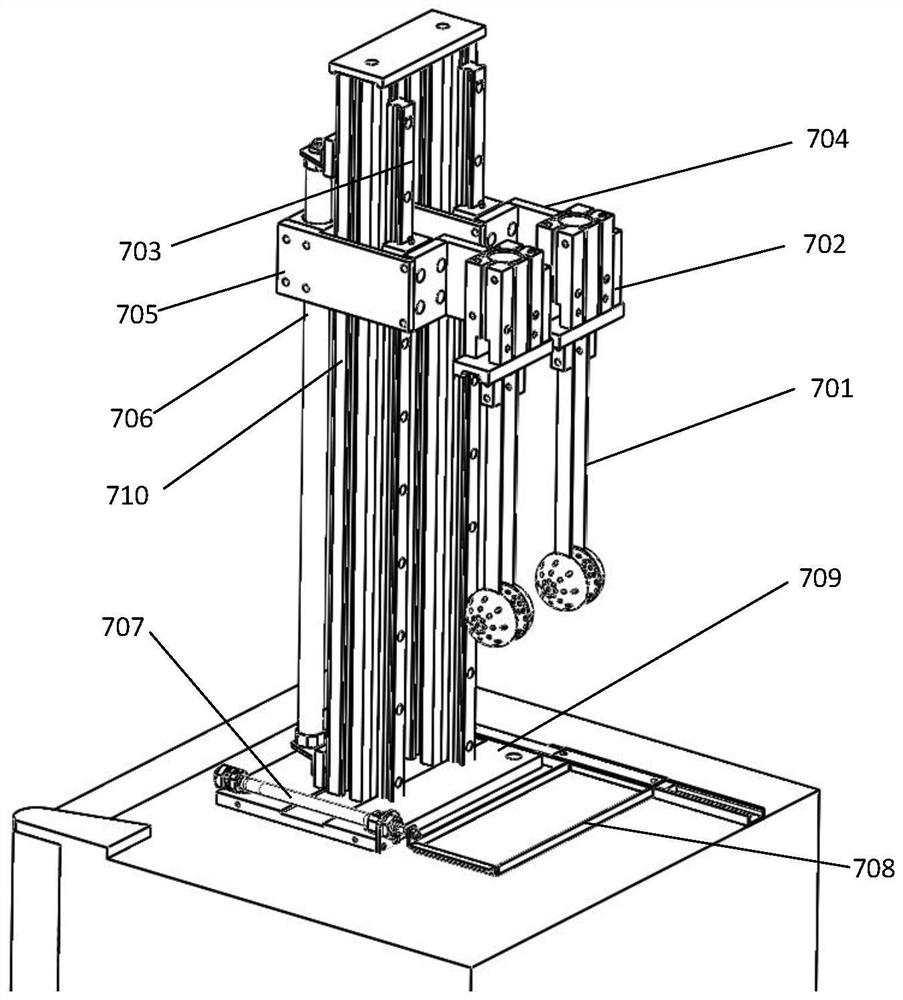

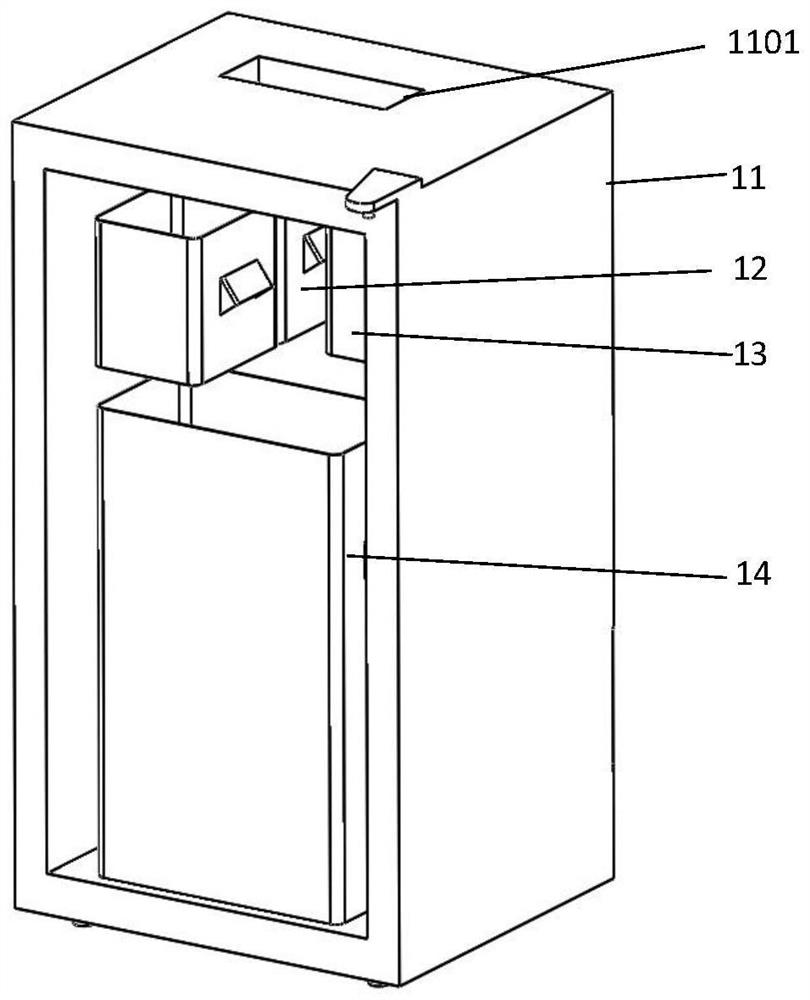

[0030] like Figure 1-Figure 9 As shown, a fully automatic milk tea production equipment includes a low temperature box 11, a joint robot 10, a pearl feeding cylinder 12, a sugar supply machine 3, a hot water machine, an ice machine 4, a normal temperature water supply machine, a tea bucket 5, and a cup Mechanism, cup sealing machine 8 and multiple discharge faucets, low temperature box 11, pearl feeding cylinder 12, sugar supply machine 3, hot water machine, ice maker 4, normal temperature water supply machine, tea barrel 5, cup discharge mechanism and sealing The cup machine 8 is arranged around the joint robot 10 and inside the main frame 1, the pearl feeding cylinder 12 and the milk feeding cylinder 14 are placed in the low temperature box 11, and a plurality of discharge faucets are used to supply liquid to the milk tea cups Raw materials, the bottoms of multiple discharge faucets are sequentially connected to the hot water machine, the tea barrel 5, the normal temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com