Mechanical demolding device for steel core mold of prefabricated hollow slab beam

A hollow plate beam and demoulding device technology, which is applied to unloading devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult installation and removal, cumbersome operation of steel core molds, etc., and achieves high turnover efficiency and strict construction steps. Rigorous and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

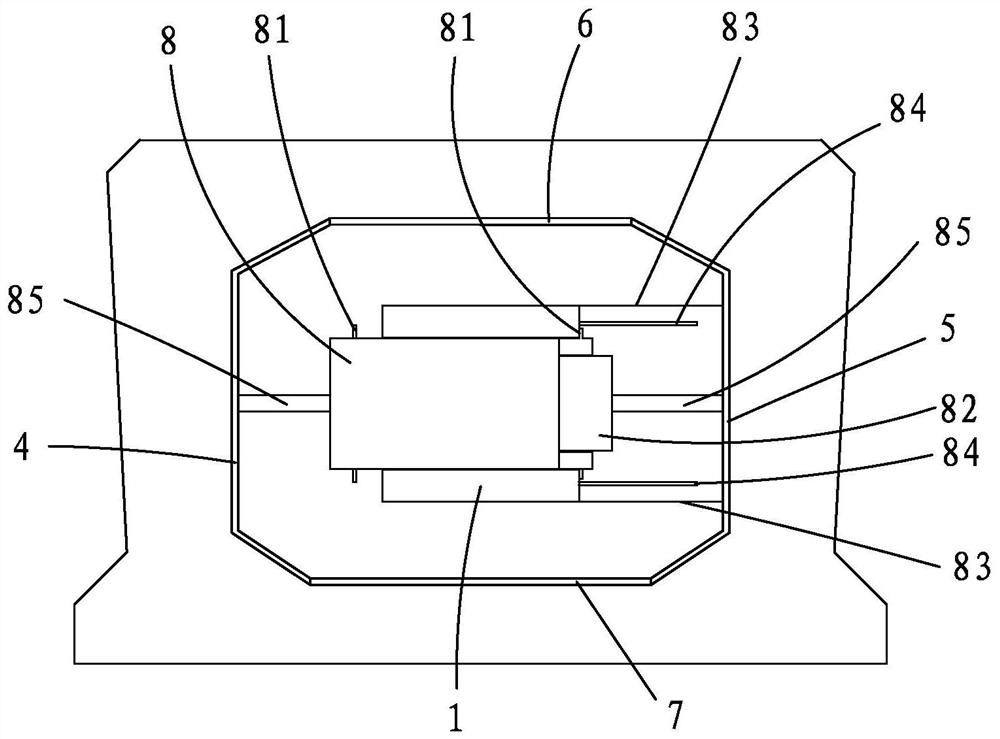

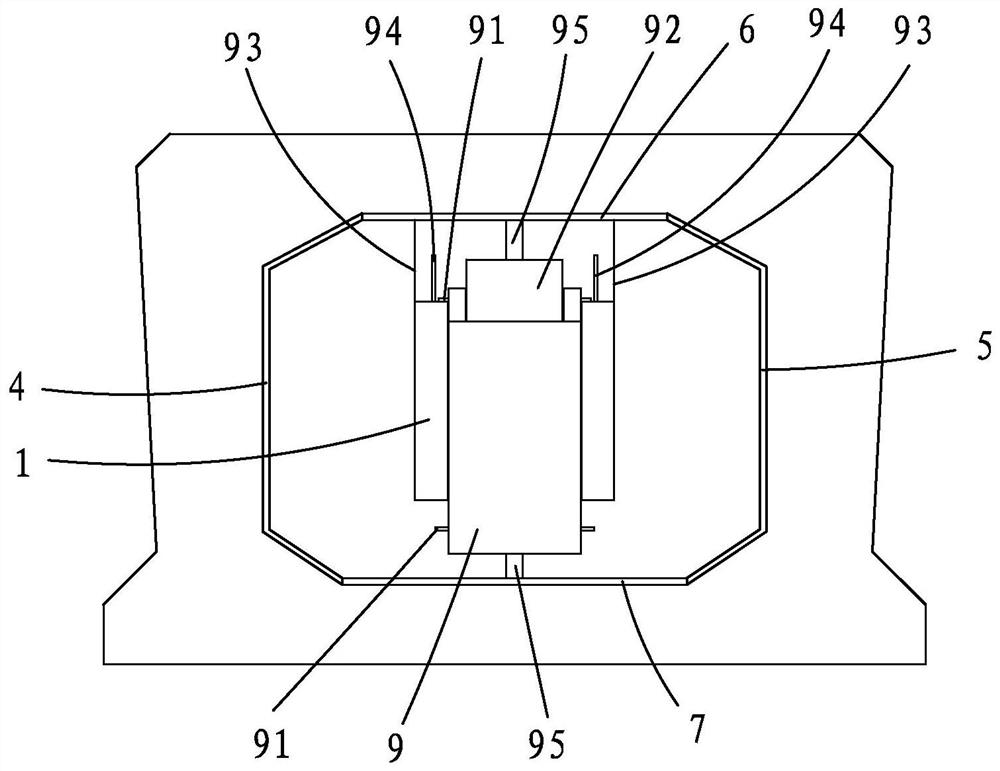

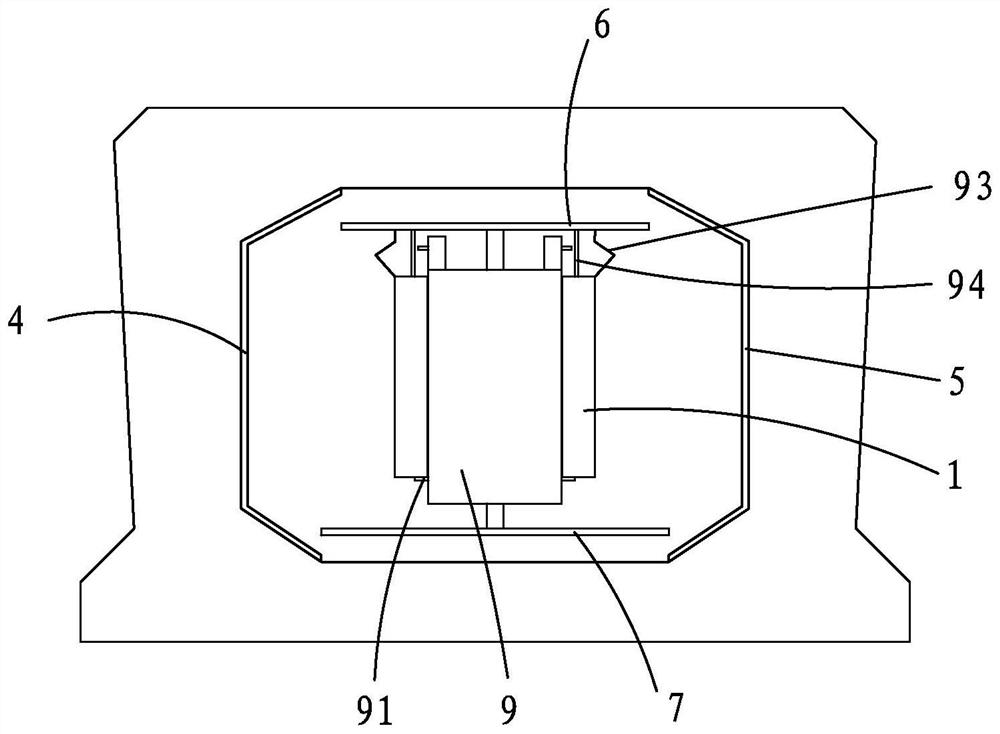

[0036] The embodiment of the present invention solves the shortcomings of the mandrel of the prefabricated hollow slab girder in the prior art by providing a mechanical demoulding device for the steel mandrel of the prefabricated hollow slab girder, and realizes the technical effect of conveniently installing and removing the steel formwork.

[0037] The technical solution in the embodiment of the present invention is to solve the above-mentioned shortcomings. The general idea is as follows: the support frame is placed in the hollow position of the prefabricated hollow slab beam, and the telescopic device is used to cooperate with the limit rope and the limit rod to install the steel formwork and the detachment rod in an orderly manner. Each telescopic device controls the movement of two steel formworks. When the steel formwork is unfolded, a steel core mold is formed. When the steel formwork is retracted, it is demoulding. After demoulding, the support frame can be directly ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com